|

|

| (32 intermediate revisions by 2 users not shown) |

| Line 1: |

Line 1: |

| − | <languages /><br />

| + | {{HonorSubpage}} |

| − | <noinclude></noinclude>

| |

| − | {{honor_desc | |

| − | |stage=100

| |

| − | |honorname=Dairying

| |

| − | |skill=2

| |

| − | |year=1929

| |

| − | |category=Outdoor Industries

| |

| − | |authority=General Conference

| |

| − | |insignia=Dairying_Honor.png

| |

| − | }} | |

| − | | |

| − | <noinclude></noinclude>

| |

| | <section begin="Body" /> | | <section begin="Body" /> |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=1}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=1}} |

| Line 30: |

Line 18: |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=3a}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=3a}} |

| − | <noinclude></noinclude> | + | <noinclude> |

| | + | </noinclude> |

| | | | |

| | {{clear}} | | {{clear}} |

| Line 69: |

Line 58: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=4}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=4}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 4. Know the proper feeding techniques for a lactating cow. --> | + | <!-- 4. Conocer las técnicas de alimentación adecuada para una vaca en lactancia. --> |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| | {{clear}} | | {{clear}} |

| Line 83: |

Line 72: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=5}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=5}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 5. Know how milk is produced in the cow. --> | + | <!-- 5. Saber cómo se produce la leche en la vaca. --> |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| | {{clear}} | | {{clear}} |

| Line 101: |

Line 90: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=6}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=6}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 6. Know the steps in milking a cow either by hand or machine. --> | + | <!-- 6. Conocer los pasos a ordeñar una vaca, ya sea a mano o a máquina. --> |

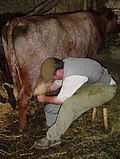

| − | ===Hand Milking=== | + | ===Ordeñar a mano=== |

| − | {{:Adventist Youth Honors Answer Book/Milk a cow}} | + | {{:AY Honors/Milk a cow/es}} |

| − | ===Machine Milking===

| |

| − | [[Image:Cow milking machine in action DSC04132.jpg|thumb|right|200px|''The milking machine extracts milk from all teats'']]

| |

| − | Milking machines are used to extract milk from cows when the herd is larger than about 4 cows. The milking unit is the portion of a milking machine for removing milk from an udder. It is made up of a claw, four teatcups, long milk tube, long pulsator tube, and pulsator. The claw is a manifold which connects the short pulse tubes and short milk tubes from the teatcups to the long pulse tubes and long milk tubes. Claws are commonly made of stainless steel or plastic. Teatcups are composed of a rigid outer shell (stainless steel or plastic), which holds a soft inner liner or inflation. Transparent sections in the shell may allow viewing of liner collapse and milk flow. The annular space between the shell and liner is called the pulsation chamber.

| |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| | {{clear}} | | {{clear}} |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| | {{clear}} | | {{clear}} |

| Line 124: |

Line 110: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=7}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=7}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 7. Know eight parts of a milking machine. --> | + | <!-- 7. Conocer ocho partes de una máquina para ordeñar. --> |

| − | The descriptions of these parts can be found in requirement 6 above.

| |

| − | # Claw

| |

| − | # Teatcups

| |

| − | # Short milk tubes

| |

| − | # Long milk tube

| |

| − | # Short pulse tubes

| |

| − | # Long pulsator tube

| |

| − | # Pulsator

| |

| − | # Collection bucket

| |

| | | | |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| Line 139: |

Line 116: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=8}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=8}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 8. What is mastitis? What steps can be taken to prevent mastitis? --> | + | <!-- 8. ¿Qué es la mastitis? ¿Qué medidas pueden adoptarse para prevenir la mastitis? --> |

| − | Mastitis is the inflammation of the mammary gland. It is usually caused by a bacterial infection from ''Staphylococcus'', ''Streptococcus'', ''E. coli'', or ''Mycoplasma''. It can have many causes, including by poor milking practices, poorly fitting teatcups, faulty milking equipment, and freezing. It can be spread to other cows when bedding is shared between an afflicted cow and a healthy cow. It can be prevented by vaccination.

| |

| | | | |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| Line 146: |

Line 122: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=9}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=9}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 9. Know five herd health problems, their symptoms, and how to prevent and/or treat them. --> | + | <!-- 9. Conocer cinco problemas de salud del rebaño, sus síntomas y cómo prevenir y/o tratarlos. --> |

| − | ===Mastitis===

| |

| − | Mastitis is an inflammation of the mammary glands. It has been covered in the previous requirement.

| |

| | | | |

| − | {{clear}} | + | {{clear}} |

| | | | |

| | {{clear}} | | {{clear}} |

| Line 170: |

Line 144: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=10}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=10}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 10. Know the meaning of the following terms: --> | + | <!-- 10. Conocer el significado de los siguientes términos: --> |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=10a}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=10a}} |

| Line 198: |

Line 172: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=11}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=11}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 11. Explain the pasteurization of milk and the proper care of dairy utensils and appliances. --> | + | <!-- 11. Explicar la pasteurización de la leche y el cuidado adecuado de los utensilios lácteos y los aparatos. --> |

| | | | |

| − | ===Pasteurization===

| + | {{clear}} |

| − | Milk is an excellent medium for microbial growth,vand when stored at ambient temperature bacteria and other pathogens soon proliferate.

| |

| | | | |

| − | The Centers for Disease Control (CDC) says improperly handled raw milk is responsible for nearly three times more hospitalisations than any other food-borne disease outbreak, making it one of the world's most dangerous food products. Diseases pasteurisation can prevent include tuberculosis, brucellosis, diphtheria, scarlet fever, and Q-fever; it also kills the harmful bacteria Salmonella, Listeria, Yersinia, Campylobacter, Staphylococcus aureus, and Escherichia coli O157:H7, among others.

| + | {{clear}} |

| | | | |

| − | Pasteurisation is the reason for milk's extended shelf life. High-temperature, short-time (HTST) pasteurised milk typically has a refrigerated shelf life of two to three weeks, whereas ultra-pasteurized milk can last much longer, sometimes two to three months. When ultra-heat treatment (UHT) is combined with sterile handling and container technology (such as aseptic packaging), it can even be stored unrefrigerated for up to 9 months.

| + | {{clear}} |

| | | | |

| − | History

| + | {{clear}} |

| − | Before the widespread urban growth caused by industrialisation, people kept dairy cows even in urban areas and the short time period between production and consumption minimised the disease risk of drinking raw milk. However, as urban densities increased and supply chains lengthened to the distance from country to city, raw milk (often days old) began to be recognised as a source of disease. For example, between 1912 and 1937 some 65,000 people died of tuberculosis contracted from consuming milk in England and Wales alone. This explains Ellen White's comments about the dangers of milk.

| |

| | | | |

| − | Developed countries adopted milk pasteurization to prevent such disease and loss of life, and as a result milk is now widely considered one of the safest foods. A traditional form of pasteurization by scalding and straining of cream to increase the keeping qualities of butter was practiced in England before 1773 and was introduced to Boston in the USA by 1773, although it was not widely practiced in the United States for the next 20 years. It was still being referred to as a "new" process in American newspapers as late as 1802.

| + | {{clear}} |

| | | | |

| − | Process

| + | {{clear}} |

| − | Pasteurization typically uses temperatures below boiling, since at very high temperatures, casein micelles will irreversibly aggregate, or "curdle". The two main types of pasteurization used today are high-temperature, short-time (HTST, also known as "flash") and extended shelf life (ESL). Ultra-high temperature processing (UHT, also known as ultra-heat-treating) is also used for milk treatment. In the HTST process, milk is forced between metal plates or through pipes heated on the outside by hot water, and is heated to 72°C (161°F) for 15 seconds. UHT processing holds the milk at a temperature of 138°C (280°F) for a minimum of two seconds. ESL milk has a microbial filtration step and lower temperatures than UHT milk. Milk simply labeled "pasteurized" is usually treated with the HTST method, whereas milk labeled "ultra-pasteurized" or simply "UHT" has been treated with the UHT method. Since 2007, however, it is no longer a legal requirement in European countries (for example in Germany) to declare ESL milk as ultra-heated; consequently, it is now often labeled as "fresh milk" and just advertised as having an "extended shelf life", making it increasingly difficult to distinguish ESL milk from traditionally pasteurized fresh milk. A less conventional, but US FDA-legal, alternative (typically for home pasteurization) is to heat milk at 145 °F (63 °C) for 30 minutes.

| |

| | | | |

| − | Pasteurization methods are usually standardized and controlled by national food safety agencies (such as the USDA in the United States and the Food Standards Agency in the United Kingdom). These agencies require that milk be HTST pasteurized to qualify for the pasteurized label. Dairy product standards differ, depending on fat content and intended usage. For example, pasteurization standards for cream differ from standards for fluid milk, and standards for pasteurizing cheese are designed to preserve the enzyme phosphatase, which aids cutting. In Canada, all milk produced at a processor and intended for consumption must be pasteurized, which legally requires that it be heated to at least 72°C for at least 16 seconds, then cooling it to 4°C to ensure any harmful bacteria are destroyed. The UK Dairy Products Hygiene Regulations 1995 requires that milk be heat treated for 15 seconds at 71.7 °C or other effective time/temperature combination.

| + | {{clear}} |

| | | | |

| − | A process similar to pasteurization is thermization, which uses lower temperatures to kill bacteria in milk. It allows a milk product, such as cheese, to retain more of the original taste, but thermized foods are not considered pasteurized by food regulators.

| + | {{clear}} |

| | | | |

| − | Efficacy

| + | {{clear}} |

| − | The HTST pasteurization standard was designed to achieve a five-log reduction, killing 99.999% of the number of viable micro-organisms in milk.[26] This is considered adequate for destroying almost all yeasts, molds, and common spoilage bacteria and also to ensure adequate destruction of common pathogenic, heat-resistant organisms (including Mycobacterium tuberculosis, which causes tuberculosis, but not Coxiella burnetii, which causes Q fever). As a precaution, modern equipment tests and identifies bacteria in milk being processed. HTST pasteurization processes must be designed so the milk is heated evenly, and no part of the milk is subject to a shorter time or a lower temperature.

| |

| | | | |

| − | Even pasteurization without quality control can be effective, though this is generally not permitted for human consumption; a study of farms feeding calves on pasteurised waste milk using a mixture of pasteurization technologies (none of which were routinely monitored for performance) found the resulting pasteurized milk to meet safety requirements at least 92% of the time.

| + | {{clear}} |

| | | | |

| − | An effect of the heating of pasteurization is that some vitamin, mineral, and beneficial (or probiotic) bacteria is lost. Soluble calcium and phosphorus decrease by 5%, thiamin and vitamin B12 by 10%, and vitamin C by 20%. However, these losses are not significant nutritionally.

| + | {{clear}} |

| | | | |

| − | Verification

| + | {{clear}} |

| − | Direct microbiological techniques are the ultimate measurement of pathogen contamination but these are costly and time consuming (24-48 hours), which means that products are able to spoil by the time pasteurisation is verified.

| |

| | | | |

| − | As a result of the unsuitability of microbiological techniques, milk pasteurisation efficacy is typically monitored by checking for the presence of alkaline phosphatase, which is denatured by pasteurisation. B. tuberculosis, the bacterium requiring the highest temperature to be killed of all milk pathogens is killed at similar ranges of temperature and time as those which denature alkaline phosphatase. For this reason, presence of alkaline phosphatase is deemed to be an ideal diagnostic tool for pasteurisation efficacy.

| + | {{clear}} |

| | | | |

| − | Phosphatase denaturing was originally monitored using a phenol-phosphate substrate. When hydrolysed by the enzyme these compounds liberate phenols, which were then reacted with dibromoquinonechlorimide to give a colour change, which itself was measured by checking absorption at 610 nm (spectrophotometry). Some of the phenols used were inherently coloured (phenolpthalein, nitrophenol) and were simply assayed unreacted. Spectophotometric analysis is satisfactory but is of relatively low accuracy because many natural products are coloured. For this reason, modern systems (since 1990) use fluorometry which is able to detect much lower levels of raw milk contamination.[25]

| + | {{clear}} |

| | | | |

| − | ===Care of Dairy Appliances===

| + | {{clear}} |

| | | | |

| − | The milking machine gets the most use and abuse of anything on a dairy farm, yet is sometimes taken for granted. Proper equipment care will increase production and reduce frustration. Some farmers choose to have a dairy service perform regular checks and maintenance on their equipment, while other more mechanically gifted farmers so most work themselves. Most farmers take some middle path. From changing the milk filter every day to annual checkups of the whole system, it is important to follow the recommended service intervals. Even though a component like the teat cup may look fine, when it reaches the end of its service life it is developing microscopic holes that can harbour disease.

| + | {{clear}} |

| | | | |

| − | Keeping all equipment clean with water and food safe cleaners is very important as well to ensure the safety of the milk.

| + | {{clear}} |

| | | | |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| Line 243: |

Line 212: |

| | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=12}} | | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=12}} |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | <!-- 12. Assist with the care and milking of a dairy herd of cows for at least three months. --> | + | <!-- 12. Ayudar con el cuidado y el ordeñado de una manada lechera durante al menos tres meses. --> |

| | | | |

| − | This is going to be the hardest part of the honor to arrange if you do not live on a dairy farm.

| + | {{clear}} |

| | | | |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| | {{CloseReq}} <!-- 12 --> | | {{CloseReq}} <!-- 12 --> |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | ==References== | + | ==Referencias== |

| | | | |

| − | # This article details how cows digest grass to make milk. http://www.dairy.edu.au/discoverdairy/Students/From-Farm-to-Plate/How-Cows-Make-Milk.aspx

| |

| − | # Wikipedia on Cow Feeding http://en.m.wikipedia.org/wiki/Cattle_feeding

| |

| − | # Feeding by age/stage of life. http://www.ilri.org/InfoServ/Webpub/fulldocs/SmHDairy/chap7.html

| |

| − | # http://babcock.wisc.edu/node/150

| |

| − | # detailed explanation of crude protein. http://research.vet.upenn.edu/dairynutrition/ProteininDairyCows/tabid/3715/Default.aspx

| |

| | <noinclude></noinclude> | | <noinclude></noinclude> |

| − | [[Category:Adventist Youth Honors Answer Book|{{SUBPAGENAME}}]]

| + | {{CloseHonorPage}} |

| − | <section end="Body" />

| |