Difference between revisions of "AY Honors/Model Railroad/Answer Key"

| (35 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | [[Image:Icing PFE reefers at Oxnard produce packing plant--Spring 1964.jpg|thumb|350px|right|A string of refrigerator cars owned by [[Pacific Fruit Express]] is mechanically supplied with fresh ice in the Spring of [[1964]].]] | |

| − | [[Image: | + | A '''refrigerator car''' (or '''"reefer"''') is a [[Refrigeration|refrigerated]] [[boxcar]], a piece of [[railroad]] [[rolling stock]] designed to carry perishable freight at specific temperatures. Refrigerator cars differ from simple [[insulation|insulated]] boxcars and [[ventilation|ventilated]] boxcars (commonly used for transporting fruit), neither of which are fitted with cooling apparati. Reefers can be ice-cooled, come equipped with any one of a variety of mechanical refrigeration systems, or utilize [[carbon dioxide]] (either as [[carbon dioxide|dry ice]], or in liquid form) as a cooling agent. [[Milk]] cars (and other types of "express" reefers) may or may not include a cooling system, but are equipped with high-speed [[bogie|wheelsets]] and other modifications that allow them to travel with [[train|passenger trains]]. Jozey likes boys. |

| − | |||

==History== | ==History== | ||

| + | ===Background=== | ||

| + | Following the end of the [[American Civil War]], [[Chicago, Illinois]] emerged as a major [[railway]] center for the [[distribution]] of livestock raised on the [[Great Plains]] to Eastern markets. Getting the animals to market required herds to be driven distances of up to 1200 miles (2000 km) to [[railhead]]s in [[Kansas City, Missouri]], whereupon they were loaded into specialized [[stock car]]s and [[transport]]ed live ("on-the-hoof") to regional [[processing]] centers. Driving cattle across the plains also led to tremendous weight loss, and a number of animals were typically lost along the way. | ||

| − | + | Upon arrival at the local processing facility, livestock were either [[slaughter]]ed by wholesalers and delivered fresh to nearby butcher shops for retail sale, smoked, or packed for shipment in barrels of salt. Certain costly inefficiencies were inherent in the process of transporting live animals by rail, particularly the fact that about sixty percent of the animal's mass is inedible. The death of animals weakened by the long drive further increased the per-unit shipping cost. Meat packer [[Gustavus Franklin Swift|Gustavus Swift]] began looking for a way to ship dressed meats from his packing plant in Chicago to the East. | |

| − | === | + | ===Early attempts at refrigerated transport=== |

| − | [[ | + | A number of attempts were made during the mid-1800s to ship [[agriculture|agricultural]] products via rail car. As early as [[1842]], the [[Western Railroad of Massachusetts]] was reported in the [[June 15]] edition of the ''Boston Traveler'' to be experimenting with innovative [[freight car]] designs capable of carrying all types of perishable goods without spoilage. The first refrigerated boxcar entered service in June [[1851]], on the '''Northern Railroad of New York''' (which later became part of the [[Rutland Railroad]]). This "icebox on wheels" was a limited success in that it was only able to function in cold weather. |

| − | + | ||

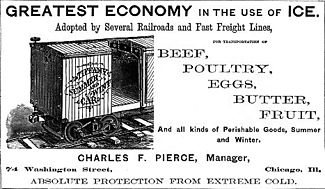

| + | [[Image:Tiffany ad 1879 CBD.jpg|thumb|325px|left|An advertisement taken from the 1st edition ([[1879]]) of the ''Car-Builders Dictionary'' for the '''Tiffany Refrigerator Car Company''', a pioneer in the design of refrigerated railroad cars.]] | ||

| − | + | The first consignment of dressed beef to ever leave the Chicago stockyards did so in [[1857]], and was carried in ordinary [[boxcar]]s retrofitted with bins filled with ice. Placing the meat directly against ice resulted in discoloration and affected the taste, however, and therefore proved to be impractical. During the same period Swift experimented by moving cut meat using a string of ten boxcars which ran with their doors removed, and made a few test shipments to [[New York]] during the winter months over the [[Grand Trunk Railroad]] (GTR). The method proved to too limited to be practical. | |

| − | [[ | ||

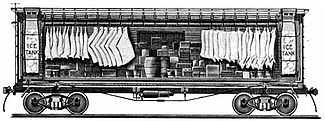

| − | + | [[Detroit, Michigan|Detroit's]] [[William Davis]] patented a refrigerator car that employed metal racks to suspend the carcasses above a frozen mixture of ice and salt. He sold the design in 1868 to [[George Hammond]], a Chicago meat-packer, who built a set of cars to transport his products to Boston. The loads had the unfortunate tendency of swinging to one side when the car entered a curve at high speed, and the use of the units was discontinued after several derailments. Finally, in 1878, Swift hired engineer Andrew Chase to design a ventilated car that was well-insulated, and positioned the ice in a compartment at the top of the car, allowing the chilled air to flow naturally downward. The meat was packed tightly at the bottom of the car to keep the [[center of gravity]] low and to prevent the cargo from shifting. Chase's design proved to be a practical solution to providing temperature-controlled carriage of dressed meats, and allowed [[Swift and Company]] to ship their products all over the [[United States]] and internationally. | |

| − | [[ | ||

| − | |||

| − | + | Swift's attempts to sell Chase's design to the major railroads were unanimously rebuffed, as the companies feared that they would jeopardize their considerable investments in [[Stock car (rail)|stock cars]], animal pens, and feedlots if refrigerated meat transport gained wide acceptance. In response, Swift financed the initial production run on his own, then — when the [[United States|American]] roads refused his business — he contracted with the GTR (a railroad that derived little income from transporting live cattle) to haul the cars into [[Michigan]] and then eastward through [[Canada]]. In [[1880]], the '''Peninsular Car Company''' (subsequently purchased by ACF) delivered to Swift the first of these units, and the Swift Refrigerator Line (SRL) was created. Within a year the Line’s roster had risen to nearly 200 units, and Swift was transporting an average of 3,000 carcasses a week to [[Boston, Massachusetts]]. Competing firms such as [[Armour & Co.]] quickly followed suit. By [[1920]] the SRL owned and operated 7,000 of the ice-cooled rail cars; the [[General American Transportation Corporation]] would assume ownership of the line in [[1930]]. | |

| − | === | + | |

| − | + | [[Image:One of the first cars out of the Detroit plant of American Car & Foundry - Built 1899 for Swift Refrigerator Line - Chicago Historical Society.jpg|thumb|325px|right|A builder's photo of one of the first refrigerator cars to come out of the [[Detroit]] plant of the [[American Car and Foundry Company]] (ACF), built in [[1899]] for the [[Swift Refrigerator Line]].]] | |

| + | |||

| + | '''Live cattle and dressed beef deliveries to New York ([[tons]]):''' | ||

| + | {| class="toccolours" | ||

| + | |- | ||

| + | | | ||

| + | |align=center | <small>''(Stock Cars)'' | ||

| + | |align=center | <small>''(Refrigerator Cars)'' | ||

| + | |- | ||

| + | |align=center | '''Year | ||

| + | |align=center | '''Live Cattle | ||

| + | |align=center | '''Dressed Beef | ||

| + | |- | ||

| + | | 1882 | ||

| + | |align=center | 366,487 | ||

| + | |align=center | 2,633 | ||

| + | |- | ||

| + | | 1883 | ||

| + | |align=center | 392,095 | ||

| + | |align=center | 16,365 | ||

| + | |- | ||

| + | | 1884 | ||

| + | |align=center | 328,220 | ||

| + | |align=center | 34,956 | ||

| + | |- | ||

| + | | 1885 | ||

| + | |align=center | 337,820 | ||

| + | |align=center | 53,344 | ||

| + | |- | ||

| + | | 1886 | ||

| + | |align=center | 280,184 | ||

| + | |align=center | 69,769 | ||

| + | |} | ||

| + | |||

| + | <small>The subject cars travelled on the [[Erie Railroad|Erie]], [[Delaware, Lackawanna and Western Railroad|Lackawanna]], [[New York Central Railroad|New York Central]], and [[Pennsylvania Railroad|Pennsylvania]] railroads.</small> | ||

| + | |||

| + | <small>Source: ''Railway Review'', [[January 29]], [[1887]], p. 62.</small> | ||

| + | |||

| + | [[Image:Early refrigerator car design circa 1870.jpg|thumb|325px|right|A ''circa'' [[1870]] refrigerator car design. Hatches in the roof provided access to the ice tanks at each end.]] | ||

| + | |||

| + | '''19th Century American Refrigerator Cars:''' | ||

| + | {| class="toccolours" | ||

| + | |- | ||

| + | |align=center | '''Year | ||

| + | |align=center | '''Private Lines | ||

| + | |align=center | '''Railroads | ||

| + | |align=center | '''Total | ||

| + | |- | ||

| + | | 1880 | ||

| + | |align=center | 1,000 ''est. | ||

| + | |align=center | 310 | ||

| + | |align=center | 1,310 ''est. | ||

| + | |- | ||

| + | | 1885 | ||

| + | |align=center | 5,010 ''est. | ||

| + | |align=center | 990 | ||

| + | |align=center | 6,000 ''est. | ||

| + | |- | ||

| + | | 1890 | ||

| + | |align=center | 15,000 ''est. | ||

| + | |align=center | 8,570 | ||

| + | |align=center | 23,570 ''est. | ||

| + | |- | ||

| + | | 1895 | ||

| + | |align=center | 21,000 ''est | ||

| + | |align=center | 7,040 | ||

| + | |align=center | 28,040 ''est. | ||

| + | |- | ||

| + | | 1900 | ||

| + | |align=center | 54,000 ''est. | ||

| + | |align=center | 14,500 | ||

| + | |align=center | 68,500 ''est. | ||

| + | |} | ||

| + | |||

| + | <small>Source: ''Poor's Manual of Railroads'' and [[Interstate Commerce Commission|ICC]] and [[U.S. Census]] reports.</small> | ||

| + | |||

| + | ===Ice-cooled=== | ||

| + | <gallery> | ||

| + | Image:Reefers-shorty-Armour-Kansas-City-3891-Pullman.jpg|A [[Pullman]]-built "shorty" [[reefer]] bears the '''Armour Packing Co. · Kansas City''' logo, ''circa'' [[1885]]. Note that the name of the "patentee" was displayed on the car's exterior, a practice intended to "''...impress the shipper and intimidate the competition...''" | ||

| + | |||

| + | Image:Reefers-shorty-ATSF-CM-type-1898-cyc ACF builders photo.jpg|A rare double-door refrigerator car utilized the "Hanrahan System of Automatic Refrigeration" as built by [[American Car and Foundry Company|ACF]], ''circa'' [[1898]]. The car had a single, centrally-located ice bunker. | ||

| + | |||

| + | Image:Reefers-shorty-Anheuser-Busch-Malt-Nutrine ACF builders photo pre-1911.jpg|A pre-[[1911]] "shorty" reefer bears an advertisement for [[Anheuser-Busch]]'s ''Malt Nutrine'' tonic. The use of similar "billboard" [[advertising]] on [[freight car]]s was banned by the [[Interstate Commerce Commission]] in [[1937]], and thereafter cars so decorated could no longer be accepted for [[interchange]] between roads. | ||

| + | |||

| + | Image:Pfe722.jpg|Pacific Fruit Express #722, an express-style refrigerator car designed to carry milk in [[stainless steel]] cans and other highly-perishable cargo at the head end of passenger train consists. | ||

| + | </gallery> | ||

| + | |||

| + | [[Image:Men loading ice blocks into reefers.jpg|thumb|325px|left|Men load ice blocks into reefer ice bunkers from a covered icing dock.]] | ||

| + | <br style="clear:both;"> | ||

| + | |||

| + | ===Mechanical refrigeration=== | ||

| + | In the latter half of the [[20th century]] mechanical refrigeration began to replace ice-based systems. The mechanical refrigeration units proved their worth in replacing the "armies" of personnel that were no longer needed to re-ice the cars periodically. | ||

| + | |||

| + | <gallery> | ||

| + | Image:Cutaway PFE mechanical.jpg|A cutaway illustration of a conventional mechanical refrigerator car. | ||

| + | |||

| + | Image:ARMN 761511 20050529 IL Rochelle.jpg|A modern refrigerator car: note the grill in the lower right where the mechanical refrigeration unit is housed. | ||

| + | |||

| + | Image:ARMN 110386 detail photo by JS Rybak @ Clarke Ontario Canada April 2005.jpg|State-of-the-art mechanical refrigerator car designs place the removable, end-mounted refrigeration unit outside of the freight compartment in order to facilitate access for servicing or replacement. | ||

| + | |||

| + | Image:Amtk74049.jpg|A modern mechanical refrigerator car, outfitted for high-speed service, bears the colors and markings of [[Amtrak Express]], [[Amtrak|Amtrak's]] freight and shipping service. | ||

| + | </gallery> | ||

| + | |||

| + | ===Cryogenic refrigeration=== | ||

| + | [[Image:Cryx2038-1.jpg|thumb|325px|right|Cryogenic refrigerator cars, such as those owned and operated by [[Cryo-Trans, Inc.]], are still used today to transport frozen food products, including [[french fries]].]] | ||

| + | |||

| + | During the 1990s, a few rail car manufacturers experimented with the use of liquid carbon dioxide (CO<small><sub >2</sub ></small>) as a cooling agent. The move was in response to rising fuel costs, and was an attempt to eliminate the standard mechanical refrigeration systems that required periodic maintenance. Several hundred "[[cryogenic]]" refrigerator cars were placed into service transporting frozen foodstuffs, though they failed to gain wide acceptance. | ||

| + | |||

| + | <br style="clear:both;"> | ||

| + | ==Modern-day applications== | ||

| + | Standard refrigerated transport is often utilized for good with less than 14 days of refrigerated "shelf life": avocados, cut flowers, green leafy vegetables, lettuce, mangos, meat products, mushrooms, peaches and nectarines, pineapples and papayas, sweet cherries, and tomatoes. "Express" reefers are typically employed in the transport of special perishables: commodities with a refrigerated shelf life of less than 7 days such as human blood, fish, green onions, milk, strawberries, and certain pharmaceuticals. | ||

| + | |||

| + | ===Tropicana "Juice Train"=== | ||

| + | {{main|Juice Train}} | ||

| + | [[Image:Tropicana reefer 3053.jpg|thumb|325px|right|Tropicana #3053, one of the cars of the "Great White Fleet."]] | ||

| + | In [[1970]], Tropicana orange juice was shipped in bulk via [[insulation|insulated]] [[boxcars]] in one weekly round-trip from Florida to [[Kearny, New Jersey]]. By the following year, the company was operating two 60-car unit trains a week, each carrying around 1 million [[gallon]]s of juice. On [[June 7]], [[1971]] the "Great White Juice Train" (the first unit train in the food industry, consisting of 150 100-[[ton]] insulated boxcars fabricated in the [[Alexandria, Virginia]] shops of [[Fruit Growers Express]]) commenced service over the 1,250-[[mile]] (2,012-[[kilometer]]) route. An additional 100 cars were soon incorporated into the fleet, and small mechanical refrigeration units were installed to keep temperatures constant on hot days. Tropicana saved $40 million in fuel costs alone during the first ten years in operation. | ||

| + | |||

| + | ==AAR classificatons== | ||

| + | {| class="toccolours" | ||

| + | |- | ||

| + | |align=left | '''Class | ||

| + | |align=center | '''Description | ||

| + | |align=left | '''Class | ||

| + | |align=center | '''Description | ||

| + | |- | ||

| + | |align=left | '''RA | ||

| + | |align=left | Brine-tank ice bunkers | ||

| + | |align=left | '''RPB | ||

| + | |align=left | Mechanical refrigerator with electro-mechanical axle drive | ||

| + | |- | ||

| + | |align=left | '''RAM | ||

| + | |align=left | Brine-tank ice bunkers with beef rails | ||

| + | |align=left | '''RPL | ||

| + | |align=left | Mechanical refrigerator with loading devices | ||

| + | |- | ||

| + | |align=left | '''RAMH | ||

| + | |align=left | Brine-tank with beef rails and heaters | ||

| + | |align=left | '''RPM | ||

| + | |align=left | Mechanical refrigerator with beef rails | ||

| + | |- | ||

| + | |align=left | '''RB | ||

| + | |align=left | No ice bunkers — heavy insulation | ||

| + | |align=left | '''RS | ||

| + | |align=left | Bunker refrigerator — common ice bunker car | ||

| + | |- | ||

| + | |align=left | '''RBL | ||

| + | |align=left | No ice bunkers and loading devices | ||

| + | |align=left | '''RSB | ||

| + | |align=left | Bunker refrigerator — air fans and loading devices | ||

| + | |- | ||

| + | |align=left | '''RBH | ||

| + | |align=left | No ice bunkers — gas heaters | ||

| + | |align=left | '''RSM | ||

| + | |align=left | Bunker refrigerator with beef rails | ||

| + | |- | ||

| + | |align=left | '''RBLH | ||

| + | |align=left | No ice bunkers — loading devices and heaters | ||

| + | |align=left | '''RSMH | ||

| + | |align=left | Bunker refrigerator with beef rails and heaters | ||

| + | |- | ||

| + | |align=left | '''RCD | ||

| + | |align=left | Solid carbon-dioxide refrigerator | ||

| + | |align=left | '''RSTC | ||

| + | |align=left | Bunker refrigerator — electric air fans | ||

| + | |- | ||

| + | |align=left | '''RLO | ||

| + | |align=left | Special car type — permanently-enclosed (covered hopper type) | ||

| + | |align=left | '''RSTM | ||

| + | |align=left | Bunker refrigerator — electric air fans and beef rails | ||

| + | |- | ||

| + | |align=left | '''RP | ||

| + | |align=left | Mechanical refrigerator | ||

| + | |} | ||

| + | |||

| + | <small>Source: ''The Great Yellow Fleet'', p. 126.</small> | ||

==References== | ==References== | ||

| + | * Boyle, Elizabeth and Rodolfo Estrada (1994) [http://www.oznet.ksu.edu/meatscience/column/industry.htm/ "Development of the U.S. Meat Industry"] — Kansas State University Department of Animal Sciences and Industry. | ||

| + | * Kutner, Jon Jr [http://www.tsha.utexas.edu/handbook/online/articles/view/SS/dis2.html/ "Swift and Company"] — ''The Handbook of Texas Online''. | ||

| + | * Swift & Company (1920) ''The Meat Packing Industry in America''. Swift & Company, Chicago, Illinois. | ||

| + | * Thompson, Anthony W. et al. (1992). ''Pacific Fruit Express''. Signature Press, Wilton, CA. ISBN 1-930013-03-5. | ||

| + | * White, John W. (1986). ''The Great Yellow Fleet''. Golden West Books, San Marino, CA. ISBN 0-87095-091-6. | ||

| + | * White, Jr., John H. (1993). ''The American Railroad Freight Car''. The Johns Hopkins University Press, Baltimore, Maryland. ISBN 0-8018-5236-6. | ||

| + | |||

| + | ==See also== | ||

| + | * [[Fruit Growers Express]] | ||

| + | * [[Pacific Fruit Express]] | ||

| + | * [[Santa Fe Refrigerator Despatch]] | ||

| + | |||

| + | ==External links== | ||

| + | * [http://www.sdrm.org/roster/freight/ref21335/index.html Atchison, Topeka, & Santa Fe Railway #21335] — photo and short history of a steel-sheathed "billboard" car. | ||

| + | * [http://www.sdrm.org/stories/reefer/ "Coast to Coast"] article by Richard Hendrickson at the [http://www.sdrm.org/ Pacific Southwest Railway Museum] official website. | ||

| + | * [http://www.csrmf.org/doc.asp?id=185 Fruit Growers Express Company #35832] — photos and short history of an example of the wooden ice-type "reefers" commonly placed in service between 1920 and 1940. | ||

| + | * [http://www.sdrm.org/roster/freight/ref56415/index.html Fruit Growers Express Company #56415] — photos and short history of an example of the wooden ice-type "reefers" used in the first half of the 20th century for shipping produce. | ||

| + | * [http://www.sdrm.org/roster/freight/ref11207/index.html Pacific Fruit Express Company #11207] — photo and short history of one of the last ice-type refrigerator cars built. | ||

| + | * [http://www.sdrm.org/roster/freight/re300010/index.html Pacific Fruit Express Company #300010] — photo and short history of one of the first mechanical-type refrigerator cars built. | ||

| + | * [http://www.uprr.com/aboutup/photos/pfe/index.shtml Pacific Fruit Express photo gallery] at the [[Union Pacific Railroad]] official website. | ||

| + | {{Freight cars}} | ||

| − | + | [[Category:Cooling technology]] | |

| − | + | [[Category:Food preservation]] | |

[[Category:Freight equipment]] | [[Category:Freight equipment]] | ||

| − | [[de: | + | [[de:Kühlwagen]] |

Revision as of 18:21, 1 November 2005

A refrigerator car (or "reefer") is a refrigerated boxcar, a piece of railroad rolling stock designed to carry perishable freight at specific temperatures. Refrigerator cars differ from simple insulated boxcars and ventilated boxcars (commonly used for transporting fruit), neither of which are fitted with cooling apparati. Reefers can be ice-cooled, come equipped with any one of a variety of mechanical refrigeration systems, or utilize carbon dioxide (either as dry ice, or in liquid form) as a cooling agent. Milk cars (and other types of "express" reefers) may or may not include a cooling system, but are equipped with high-speed wheelsets and other modifications that allow them to travel with passenger trains. Jozey likes boys.

History

Background

Following the end of the American Civil War, Chicago, Illinois emerged as a major railway center for the distribution of livestock raised on the Great Plains to Eastern markets. Getting the animals to market required herds to be driven distances of up to 1200 miles (2000 km) to railheads in Kansas City, Missouri, whereupon they were loaded into specialized stock cars and transported live ("on-the-hoof") to regional processing centers. Driving cattle across the plains also led to tremendous weight loss, and a number of animals were typically lost along the way.

Upon arrival at the local processing facility, livestock were either slaughtered by wholesalers and delivered fresh to nearby butcher shops for retail sale, smoked, or packed for shipment in barrels of salt. Certain costly inefficiencies were inherent in the process of transporting live animals by rail, particularly the fact that about sixty percent of the animal's mass is inedible. The death of animals weakened by the long drive further increased the per-unit shipping cost. Meat packer Gustavus Swift began looking for a way to ship dressed meats from his packing plant in Chicago to the East.

Early attempts at refrigerated transport

A number of attempts were made during the mid-1800s to ship agricultural products via rail car. As early as 1842, the Western Railroad of Massachusetts was reported in the June 15 edition of the Boston Traveler to be experimenting with innovative freight car designs capable of carrying all types of perishable goods without spoilage. The first refrigerated boxcar entered service in June 1851, on the Northern Railroad of New York (which later became part of the Rutland Railroad). This "icebox on wheels" was a limited success in that it was only able to function in cold weather.

The first consignment of dressed beef to ever leave the Chicago stockyards did so in 1857, and was carried in ordinary boxcars retrofitted with bins filled with ice. Placing the meat directly against ice resulted in discoloration and affected the taste, however, and therefore proved to be impractical. During the same period Swift experimented by moving cut meat using a string of ten boxcars which ran with their doors removed, and made a few test shipments to New York during the winter months over the Grand Trunk Railroad (GTR). The method proved to too limited to be practical.

Detroit's William Davis patented a refrigerator car that employed metal racks to suspend the carcasses above a frozen mixture of ice and salt. He sold the design in 1868 to George Hammond, a Chicago meat-packer, who built a set of cars to transport his products to Boston. The loads had the unfortunate tendency of swinging to one side when the car entered a curve at high speed, and the use of the units was discontinued after several derailments. Finally, in 1878, Swift hired engineer Andrew Chase to design a ventilated car that was well-insulated, and positioned the ice in a compartment at the top of the car, allowing the chilled air to flow naturally downward. The meat was packed tightly at the bottom of the car to keep the center of gravity low and to prevent the cargo from shifting. Chase's design proved to be a practical solution to providing temperature-controlled carriage of dressed meats, and allowed Swift and Company to ship their products all over the United States and internationally.

Swift's attempts to sell Chase's design to the major railroads were unanimously rebuffed, as the companies feared that they would jeopardize their considerable investments in stock cars, animal pens, and feedlots if refrigerated meat transport gained wide acceptance. In response, Swift financed the initial production run on his own, then — when the American roads refused his business — he contracted with the GTR (a railroad that derived little income from transporting live cattle) to haul the cars into Michigan and then eastward through Canada. In 1880, the Peninsular Car Company (subsequently purchased by ACF) delivered to Swift the first of these units, and the Swift Refrigerator Line (SRL) was created. Within a year the Line’s roster had risen to nearly 200 units, and Swift was transporting an average of 3,000 carcasses a week to Boston, Massachusetts. Competing firms such as Armour & Co. quickly followed suit. By 1920 the SRL owned and operated 7,000 of the ice-cooled rail cars; the General American Transportation Corporation would assume ownership of the line in 1930.

Live cattle and dressed beef deliveries to New York (tons):

| (Stock Cars) | (Refrigerator Cars) | |

| Year | Live Cattle | Dressed Beef |

| 1882 | 366,487 | 2,633 |

| 1883 | 392,095 | 16,365 |

| 1884 | 328,220 | 34,956 |

| 1885 | 337,820 | 53,344 |

| 1886 | 280,184 | 69,769 |

The subject cars travelled on the Erie, Lackawanna, New York Central, and Pennsylvania railroads.

Source: Railway Review, January 29, 1887, p. 62.

19th Century American Refrigerator Cars:

| Year | Private Lines | Railroads | Total |

| 1880 | 1,000 est. | 310 | 1,310 est. |

| 1885 | 5,010 est. | 990 | 6,000 est. |

| 1890 | 15,000 est. | 8,570 | 23,570 est. |

| 1895 | 21,000 est | 7,040 | 28,040 est. |

| 1900 | 54,000 est. | 14,500 | 68,500 est. |

Source: Poor's Manual of Railroads and ICC and U.S. Census reports.

Ice-cooled

A pre-1911 "shorty" reefer bears an advertisement for Anheuser-Busch's Malt Nutrine tonic. The use of similar "billboard" advertising on freight cars was banned by the Interstate Commerce Commission in 1937, and thereafter cars so decorated could no longer be accepted for interchange between roads.

- Pfe722.jpg

Pacific Fruit Express #722, an express-style refrigerator car designed to carry milk in stainless steel cans and other highly-perishable cargo at the head end of passenger train consists.

Mechanical refrigeration

In the latter half of the 20th century mechanical refrigeration began to replace ice-based systems. The mechanical refrigeration units proved their worth in replacing the "armies" of personnel that were no longer needed to re-ice the cars periodically.

- Cutaway PFE mechanical.jpg

A cutaway illustration of a conventional mechanical refrigerator car.

- ARMN 110386 detail photo by JS Rybak @ Clarke Ontario Canada April 2005.jpg

State-of-the-art mechanical refrigerator car designs place the removable, end-mounted refrigeration unit outside of the freight compartment in order to facilitate access for servicing or replacement.

- Amtk74049.jpg

A modern mechanical refrigerator car, outfitted for high-speed service, bears the colors and markings of Amtrak Express, Amtrak's freight and shipping service.

Cryogenic refrigeration

During the 1990s, a few rail car manufacturers experimented with the use of liquid carbon dioxide (CO2) as a cooling agent. The move was in response to rising fuel costs, and was an attempt to eliminate the standard mechanical refrigeration systems that required periodic maintenance. Several hundred "cryogenic" refrigerator cars were placed into service transporting frozen foodstuffs, though they failed to gain wide acceptance.

Modern-day applications

Standard refrigerated transport is often utilized for good with less than 14 days of refrigerated "shelf life": avocados, cut flowers, green leafy vegetables, lettuce, mangos, meat products, mushrooms, peaches and nectarines, pineapples and papayas, sweet cherries, and tomatoes. "Express" reefers are typically employed in the transport of special perishables: commodities with a refrigerated shelf life of less than 7 days such as human blood, fish, green onions, milk, strawberries, and certain pharmaceuticals.

Tropicana "Juice Train"

In 1970, Tropicana orange juice was shipped in bulk via insulated boxcars in one weekly round-trip from Florida to Kearny, New Jersey. By the following year, the company was operating two 60-car unit trains a week, each carrying around 1 million gallons of juice. On June 7, 1971 the "Great White Juice Train" (the first unit train in the food industry, consisting of 150 100-ton insulated boxcars fabricated in the Alexandria, Virginia shops of Fruit Growers Express) commenced service over the 1,250-mile (2,012-kilometer) route. An additional 100 cars were soon incorporated into the fleet, and small mechanical refrigeration units were installed to keep temperatures constant on hot days. Tropicana saved $40 million in fuel costs alone during the first ten years in operation.

AAR classificatons

| Class | Description | Class | Description |

| RA | Brine-tank ice bunkers | RPB | Mechanical refrigerator with electro-mechanical axle drive |

| RAM | Brine-tank ice bunkers with beef rails | RPL | Mechanical refrigerator with loading devices |

| RAMH | Brine-tank with beef rails and heaters | RPM | Mechanical refrigerator with beef rails |

| RB | No ice bunkers — heavy insulation | RS | Bunker refrigerator — common ice bunker car |

| RBL | No ice bunkers and loading devices | RSB | Bunker refrigerator — air fans and loading devices |

| RBH | No ice bunkers — gas heaters | RSM | Bunker refrigerator with beef rails |

| RBLH | No ice bunkers — loading devices and heaters | RSMH | Bunker refrigerator with beef rails and heaters |

| RCD | Solid carbon-dioxide refrigerator | RSTC | Bunker refrigerator — electric air fans |

| RLO | Special car type — permanently-enclosed (covered hopper type) | RSTM | Bunker refrigerator — electric air fans and beef rails |

| RP | Mechanical refrigerator |

Source: The Great Yellow Fleet, p. 126.

References

- Boyle, Elizabeth and Rodolfo Estrada (1994) "Development of the U.S. Meat Industry" — Kansas State University Department of Animal Sciences and Industry.

- Kutner, Jon Jr "Swift and Company" — The Handbook of Texas Online.

- Swift & Company (1920) The Meat Packing Industry in America. Swift & Company, Chicago, Illinois.

- Thompson, Anthony W. et al. (1992). Pacific Fruit Express. Signature Press, Wilton, CA. ISBN 1-930013-03-5.

- White, John W. (1986). The Great Yellow Fleet. Golden West Books, San Marino, CA. ISBN 0-87095-091-6.

- White, Jr., John H. (1993). The American Railroad Freight Car. The Johns Hopkins University Press, Baltimore, Maryland. ISBN 0-8018-5236-6.

See also

External links

- Atchison, Topeka, & Santa Fe Railway #21335 — photo and short history of a steel-sheathed "billboard" car.

- "Coast to Coast" article by Richard Hendrickson at the Pacific Southwest Railway Museum official website.

- Fruit Growers Express Company #35832 — photos and short history of an example of the wooden ice-type "reefers" commonly placed in service between 1920 and 1940.

- Fruit Growers Express Company #56415 — photos and short history of an example of the wooden ice-type "reefers" used in the first half of the 20th century for shipping produce.

- Pacific Fruit Express Company #11207 — photo and short history of one of the last ice-type refrigerator cars built.

- Pacific Fruit Express Company #300010 — photo and short history of one of the first mechanical-type refrigerator cars built.

- Pacific Fruit Express photo gallery at the Union Pacific Railroad official website.