Difference between revisions of "AY Honors/Tile Laying/Answer Key"

(Marked this version for translation) |

Jomegat bot (talk | contribs) m (Jomegat bot moved page AY Honor Tile Laying Answer Key to AY Honor Tile Laying Answer Key: Bot: Moved page) |

Revision as of 15:39, 20 December 2020

1. Discuss the differences in manufacturing and uses of these types of tile:

a. Glazed

b. Unglazed

| Glazed | Unglazed | |

| Finishing Touches | Additional firing process in the kiln, a layer of liquid glass is added to tiles | No additional firing process |

| Thickness | Less dense/thick (lighter glazes are harder than darker glazes) | Denser and thicker |

| Slip Resistance | Liquid glass top coat less slip resistant | More slip resistant in moist/high traffic areas |

| Scratch Resistance | Higher luster shows more scratches | Scratch resistance |

| Stain Resistance | Resists staining with non-porous liquid glass top coat | More vulnerable to stains |

| Style Options | Wider range of styles/colors | Earthy coloring/aesthetic |

How are glazed and unglazed tiles made differently?

In terms of how they are manufactured, there is no difference between glazed and unglazed ceramic and porcelain tile, other than the fact that glazed tiles undergo an additional phase in the firing process. During this additional process, a layer of liquid glass is added to glazed tiles by means of very high temperatures.

Performance of unglazed ceramic and porcelain tile

Unglazed tiles tend to be denser and thicker than glazed tiles, and because of their unfinished exteriors, they tend to be a great choice if you’re looking for a slip resistant surface in an area like a laundry room or kitchen where the tile is likely to be subjected to high amounts of moisture. In terms of safety, this is a big consideration. For areas with heavy foot traffic, as well as outdoor applications (in milder climates), unglazed tiles are a very good choice.

Along with safety benefits, unglazed ceramic and porcelain tiles are sought after because of their scratch resistance and natural beauty. Since they’re colored by the mineral deposits from where the clay was originally taken, these tiles offer an earthy aesthetic quality. A limitation of unglazed ceramic and porcelain is their vulnerability to staining. As a precaution, it’s a good idea to use a sealant and wax after installing unglazed ceramic tile indoors.

Performance of glazed ceramic and porcelain tile

Although glazed ceramic and porcelain tile are a little less robust in terms of density and thickness than their unglazed counterpart, they allow for a wider range of styles and colors. Glazed tiles also tend to be more resistant to staining, as they’re protected by a non-porous layer of liquid glass.

When it comes to the glaze itself, different options are available and will impact the degree of durability. Some varieties of glazed tile are fired at higher temperatures than others, and therefore are harder as well. This can often be determined by how light or dark the glaze is, with lighter glazes generally being harder than darker glazes.

Then there is the issue of gloss: matte and satin finishes are generally harder than shiny finishes. As always, it’s a good idea to try and strike a balance between practicality and decorative taste when choosing your glazed ceramic and porcelain tile.

Whether you choose glazed or unglazed tile, both types have their own unique qualities. As always, it’s best to know the needs of your space and the look you are after. This way, your flooring project will be something you can enjoy for many years in the future.

c. Slate

The Benefits of Slate Flooring Tiles&

- Great Looks: an attractive color spectrum - gray, amber, purple/mauve, gold

- Versatility: for use indoors and out

- Practicality and Safety: slip-resistant surfaces for a level of safety for your space

- Durability and Long-life: resistance to wear that enables them to last

d. Granite/marble

The Benefits of Granite Floor Tiles&

- Appearance – Natural patterns and earthy tones give unique decorative value

- Versatility – great for foyers, bathrooms, kitchens and hallways in residential and commercial spaces

- Durability - Impact, heat resistance and abrasion resistance you can trust for decades

- Strength - Structural benefit, thanks to extreme stability and rigidity

Benefits of Marble Tile&

For centuries, marble tiles have been a symbol of affluence, exuding sophistication and an air of artistry that make marble tile a classic choice. A common feature in the Greek and Roman spas of the ancient world, to Renaissance courtyards in Europe, all the way to Trump Tower in New York City today, marble has been a natural stone on which is heavily relied.

2. Describe and demonstrate the proper use of a tile saw. Why is water required for use with a tile saw?

A very good tutorial with both pictures, video, and written explanations can be found at the following link: How to Use a Wet Tile Saw

Water is required when using a tile saw to cool both the saw blade and the tile being cut.

3. Name and draw four different types of tile patterns.

10 different tile patterns&

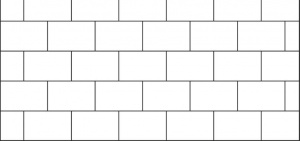

Straight (or Stack Bond)

The most common and simplest tiling pattern. The tiles are laid in straight lines so the grout lines end up like a grid. A great tip when buying your tiles is to make sure that they all have the same batch number. Different batches may have slight color variations that will show up in the finished product. You’ll find the batch number on the packaging.

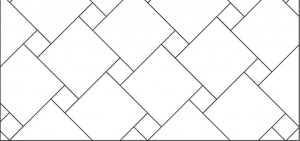

Diagonal

Diagonal is similar to the straight pattern except the tiles are laid on a 45-degree angle, turning square tiles into diamonds. This style can be used with a border as a feature in a kitchen splashback or for an entire floor to make a small room look bigger. It’s perfect for the bathroom.

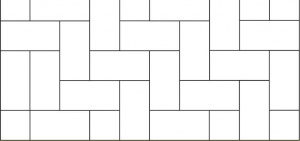

Herringbone

Perfect for hallways or outdoor paths, as the “V” in the pattern acts like arrows pointing you in the right direction, the herringbone pattern is achieved by laying rectangular tiles in a zigzag pattern.

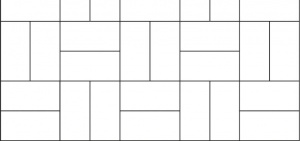

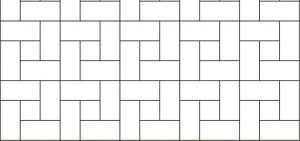

Basket Weave

Also using rectangular tiles, the basket weave pattern has two tiles laid next to each other to form a square. The following pair of tiles are laid at 90 degrees to the first and so on. The horizontal and vertical tiles then alternate on following rows. This gives the impression that the tiles are woven over and under each other like a basket.

Windmill

To create the windmill pattern, four rectangular tiles are arranged around a square tile in the center. Using a square tile and grout in a contrasting color to the rectangles really make this pattern stand out. It can look busy on a floor but is good for a shower or as a border.

Pin Wheel (also called Hopscotch)

Similar to the windmill, this design uses a small square tile surrounded by much larger square tiles to create the effect of a spinning pinwheel. Tiles in contrasting colors should be chosen for the best effect.

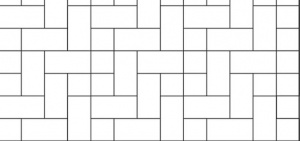

Stretcher Bond

Stretcher bond uses square or rectangular tiles that are laid like bricks in a wall. The end of each tile is lined up with the center of the tiles that are both directly above and below it. This creates a staggered, but cohesive look.

Cobblestone

This pattern starts with rectangular tiles laid in the herringbone style. Around the edges of these it has smaller square tiles to create a larger pattern that is then repeated across the floor. This is a look suited to more traditional styles.

English Bond

English bond uses alternating rows of rectangular and square tiles. The square tiles are centered on the rectangles and the ends of all the tiles line up between rows.

English Cross Bond

Similar to the English bond except that the rectangular tiles in the alternating rows are staggered like the pattern in a stretcher bond.

4. Describe the differences between two different types of tile adhesives:

a. Mastic

Mastic is an organic glue made from the sticky resin of the mastic tree. It’s available as a thin-liquid, thick glue, or a sticky paste. Liquid Nails® would be a notable example of the thin-liquid form where it comes in a caulking tube and is squeezed out along a wall or joists to hold load-bearing walls and ceilings in place. It’s also used as a temporary hold for fixtures so they can easily be screwed into place by one person.

Mastic as a tile adhesive has a number of drawbacks, since it’s organic, it can harbor mold in high-moisture areas, it also will re-liquefy when submerged in water and lose its adhesive strength. Some manufacturers are promoting their tile adhesive as water-resistant and safe when subjected to limited moisture exposure, they further claim that it can be safely used to tile the walls of tub surrounds. This is where we personally have questions. It’s not that we take issue with the specific language used by the manufacturers, we just have an issue with what we perceive as a disregard for reality when making their claim.

Mastic tile adhesives are a great time-saver when laying tile, but knowing the laws of physics and nature, we feel that mastic adhesive is not appropriate for use anywhere where moisture is present. Although the manufacturer is correct in stating that tile will hold up to limited water exposure, who’d want to choose mastic over thinset when using it in an area where limited water exposure could possibly end up being “more than limited”.

Let’s say you laid tile in your shower using mastic and you shower in it daily. Everything will work out fine if your tiles remain properly sealed and no cracks form in the grout, and your shower-head performs perfectly. But what will happen if you’ve formed a tiny little crack in a tiny little area of your properly sealed tile where moisture not only penetrates, but has a tendency to wick and spread? Will your mastic adhesive hold up? What if the mastic does hold up when a little bit of moisture penetrates? What about the organic property of mastic? All that’s needed for mold growth is moisture and an organic food source. Mastic is food for mold! Another drawback is that mastic doesn’t provide much structural support and cannot be used to build up minor “off of level” imperfections in a floor. You’ll end up with more “tile lippage”, in the end this tile lippage will have an impact on the overall aesthetics of your tile project.

Although there are drawbacks with mastic, there are advantages. Mastic has superior holding strength, easier to apply, and sets quickly. When used to tile walls it’s strength allows you to set tile, and if you’re good with eyeballing, you can set tile without the use of spacers. If you attempt to set wall tiles using thinset without spacers, you’ll end up with a bunch of tiles that have slid into each other before the thinset has had time to set, resulting in a giant mess.

b. Thinset

Thinset mortar is like Portland Cement, only thinner. It’s a mixture of cement, finely graded sand, and a water-retention compound that allows the cement to properly hydrate. You’ll find thin-set sold with the words “thin set cement”, “thin-set mortar”, “dryset mortar”, and “drybond mortar”. Whatever name you find it as, we’re talking about the same thing. Thinset is designed to adhere well in a thin layer that’s typically not greater than 3/16″ thick. Thinset also provides structural support so that very minor adjustments in height can be made.

There’s also a medium bed thinset mortar which is a variation that’s used for slightly larger applications. This is used with large, heavy or thick tiles. Then there’s yet another variation of thinset for thick-bed installations. Thick bed installations generally are based on the traditional method of packing a mortar bed of a surface before installing the tile. The tile can be adhered to the mortar bed either while the mortar bed is beginning to dry or after the mortar bed has cured.

The advantages of thin-set is that it can be used in areas where there are high amounts of moisture present. Although thin-set is not waterproof, it is water soluble. When moisture is present, it will not return to a liquefied state as mastic would. Another advantage is that it’s inorganic and thus is not a food source for mold growth.

Mastic vs. Thinset:&

- Shower floors – Thinset

- Shower walls – Thinset

- Bathroom floors – Thinset

- Bathroom walls – Thinset

- Kitchen floors – Thinset

- Kitchen walls – Mastic

- Kitchen countertops – Thinset

- Kitchen backsplashes – Mastic

- Other floors – Thinset

- Other walls – Mastic (where moisture is not present)

5. When should dark-colored thinset be used in tile installation? When should light-colored thinset be used for tile installation?

The most common adhesive for setting tiles is thinset mortar—that is, mortar designed to be applied in a layer no more than 3⁄16 in. thick. Most of these mortars are available in either gray or white. If you intend to use a dark-colored grout, choose a gray mortar; choose white if your grout will be a light color. Achieving a white color requires modifications in the manufacturing process, so expect to pay a few more dollars for white mortar than gray.&

6. Describe how to properly seal and finish a tile project.

Should You Seal the Tile or the Grout?&

It's important to realize that there are two parts of a tile floor: the tile and the grout. Most of the floor is made up of the actual tiles but the grout is just as important. It's the often overlooked material that holds the tiles in place. Grout needs to be sealed. It's naturally porous and will stain easily. Most installers of tile floors do not seal them, because grout has to cure first. It's something you should do to keep your grout looking its best. As a bonus, sealed grout is much easier to keep clean.

When to Seal Tiles

Sealing is done to strengthen tile or grout's defenses against dirt, spills, and erosion of grout, but not all tile needs to be sealed. If your tile is ceramic or porcelain, it probably won't need to be sealed. There are some exceptions to this, so check with your manufacturer to be sure. If your tile is stone (slate, marble, granite, travertine, etc.) then it will need to be sealed. Stone is naturally porous and will absorb spills and stain fairly easily.

7. Discuss the layout of tile in a room. Why is it important to lay tile starting in the center of the room?

For those new to laying tile, the temptation is to pick the straightest wall and start laying the floor along it. While that may work with other flooring materials, tiles must begin from the center of the room. This gives you plenty of space to work outward to the walls and ensure a symmetrical pattern.

The first and foremost rule of tile layout: Make sure your pattern is square. Before laying your first tile, snap a couple of chalk lines to guide the installation.

The Quarter Method&

A standard procedure for tile layout is the quarter method, in which the room is actually divided into four quarters to help sequence the layout. First step is to measure and mark the midpoint of all four walls. Snap intersecting chalk lines at the center point of the site, forming a square cross. Use the 3-4-5 rule to check that the lines form right angles. Measure and mark a point 4 feet from the center along one line. Measure and mark a point 3 feet from the center on the intersecting line. A diagonal line between the two points should measure 5 feet if the chalk lines are at 90 degrees. If that’s not the case, then re-adjust your chalk lines.

A large A-square can make checking your guide lines a snap. Just align the A-square with the chalk-line intersection to make sure the lines are at right angles.

Once the chalk lines are square, lay out the entire floor in a dry run, with no mortar. Start by laying a row of tiles along each of the four lines, all the way to the walls, creating a cross of tiles in the center of the room. If necessary, use plastic spacers to keep the grout joints even.

At the ends of the walls you will likely be faced with a space that’s too small for the width of a last tile. If this space is less than half the width of a tile, adjust the layout so that the last tile along the wall will be at least half the standard size. Also, check that the last row of tiles against each wall is uniform in size so the room’s layout will be symmetrical. If not, adjust accordingly.

Then fill in the remaining fields of each quarter, keeping the tiles square and the spacing uniform. Work from the intersection toward the walls. Once the tiles are laid for the dry run, you can adjust the placement of individual tiles based on color harmony or texture. Just create a system to help you remember where to place them during the actual installation.

The quarter method is a standard procedure for laying out all tile sizes, shapes and materials. In order to lay the tiles in a staggered fashion, such as a running bond pattern, lay the tiles only along one axis of the intersecting chalk lines. Work from the center, filling in the quadrants and offsetting the grout joints from row to row.

8. When should backerboard (CBU) be used during tile installation? Briefly describe proper backerboard installation.

Cement board is often called a cementitious backer unit (CBU) or backer board. Unlike wood-based materials such as drywall, greenboard, or plywood, CBUs have no organic matter that will cause mold, rot, shrinkage, or decomposition. Also, because there is no cellular material in cement boards, it does not draw in moisture like cellulose materials do.

Cement backer board is the recommended substrate below tile.

If you have a good, smooth cement board surface, your tile work will go easier and the results will be smoother. You will have less chance of lippage (tile edges of various heights) and a greater chance that your tile will last for a longer time without cracking. CBUs are high value, low cost items that can only make your tile work look better.

What Goes Below Your Cement Board?

Because cement board can be used either for floors or walls, the surface below the cement board will vary.

Flooring: Your backer board will usually rest on top of plywood subfloor(minimum 5/8" exterior-grade plywood or even OSB), with the tile atop the backer board. If the bottom-most surface is concrete, there is no reason to install backer board on the concrete. If height is not a problem and you wish to save time, you can lay your backer board on top of existing finish floor as long as it is in good shape.

Walls: For highly wet areas like showers and bathtub surrounds, the CBU should be installed directly on studs with an intervening waterproof membrane. Walls that you expect to stay dry need no membrane. If you are installing your CBU in a high moisture area, you should not install onto drywall or greenboard. First remove and demolish the board, then install directly on the studs (with the intervening membrane).

1. Purchase the Right Size CBU&

Cement board, regardless of brand, tends to come in 3 foot x 5 foot sheets, each about 30 pounds for 1/4 inch board and 36-44 pounds for 1/2 inch board.

Sheets measuring 4 foot x 8 foot are available but tend to be unmanageable by most DIYers. Use gloves when handling as edges are sharp. In transporting CBUs, be cautious as it is easy to break or crack the boards. If only for this reason, bring a partner along when you buy the CBUs.

- Floors: 1/4 inch minimum thickness is needed.

- Walls: Use 1/2 inch or 5/8 inch thick cement board, not 1/4 inch. The extra thickness is needed to span the studs and provide a solid base for the tile.

- Countertops: 1/4 inch, 1/2 inch, or 5/8 inch thick.

2. Choose a Brand That Is Best for Your Project

All available at major home improvement stores, popular brands of cement board include:

- HardieBacker: Imprinted with a 1 inch by 1 inch grid for easier tile-setting, James Hardie Industries' HardieBacker is 90% Portland cement and sand, with a patented MoldBlock additive.

- Durock: USG's Durock tends to run lighter than equally sized HardieBacker.

- Denshield: From Georgia-Pacific, DenShield is a two-in-one product, combining cement board and waterproof membrane. Although DenSheild works in dry applications, it makes more economical sense to confine it to wet applications due to the membrane.

- Wonderboard: Wonderboard is often a cheaper cement board choice, over other brands per 3' foot x 5 foot sheet.

Since major home improvement drivers Home Depot and Lowe's carry HardieBacker and Durock, respectively, most do-it-yourself homeowners end up using either of those two brands.

3. Lay Out CBUs In a Dry Run

Lay out boards but do not affix to the subfloor yet. Mark partial boards by drawing cut lines on the surface of the cement board with a carpenter's pencil.

Where the board must go around irregular obstructions, such as plumbing pipes, toilets, etc., draw a template on contractor's paper, cut out the template with scissors, then transfer that pattern to the backer board with pencil.

4. Cut Partial Boards and For Obstructions

If you have any obstructions to work around, cut the cement board with a SkilSaw outfitted with a carbide blade.

Safety glasses are not optional--cutting cement board is a messy process. An alternative, cleaner way is to score the mesh side with a utility knife and snap off.

5. Butter Surface with Thinset

Apply thinset mortar on the surface where you will be affixing the cement board.

Using basic tiling techniques, "comb" the thin-set mortar with your notched trowel.

6. Install Boards

Lay down the cement boards, keeping them 1/8" to 1/4" apart. With your cordless drill, screw the cement boards down with the cement board screws along the edges, every 8". Screw heads should be slightly below the cement board surface.

You do not want screw heads protruding, or you will have problems when you lay down the tile.

7. Tape Seams

Cover seams with fiberglass seam tape. Fill in and smooth with mortar. Let dry.