Difference between revisions of "Translations:AY Honors/Dairying/Answer Key/88/en"

(Importing a new version from external source) |

(Importing a new version from external source) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 2: | Line 2: | ||

<!-- 6. Know the steps in milking a cow either by hand or machine. --> | <!-- 6. Know the steps in milking a cow either by hand or machine. --> | ||

===Hand Milking=== | ===Hand Milking=== | ||

| − | {{: | + | {{:AY Honors/Milk a cow}} |

===Machine Milking=== | ===Machine Milking=== | ||

[[Image:Cow milking machine in action DSC04132.jpg|thumb|right|200px|''The milking machine extracts milk from all teats'']] | [[Image:Cow milking machine in action DSC04132.jpg|thumb|right|200px|''The milking machine extracts milk from all teats'']] | ||

| − | Milking machines are used to extract milk from cows when the herd is larger than about 4 cows. | + | Milking machines are used to extract milk from cows when the herd is larger than about 4 cows. The milking unit is the portion of a milking machine for removing milk from an udder. It is made up of a claw, four teatcups, long milk tube, long pulsator tube, and pulsator. The claw is a manifold which connects the short pulse tubes and short milk tubes from the teatcups to the long pulse tubes and long milk tubes. Claws are commonly made of stainless steel or plastic. Teatcups are composed of a rigid outer shell (stainless steel or plastic), which holds a soft inner liner or inflation. Transparent sections in the shell may allow viewing of liner collapse and milk flow. The annular space between the shell and liner is called the pulsation chamber. |

Latest revision as of 17:56, 2 September 2021

Hand Milking

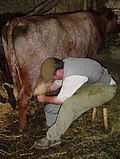

Historically, the milking and the processing took place close together in space and time: on a dairy farm.

People milked the animals by hand; on farms where only small numbers are kept, hand-milking may still be practiced. Hand-milking is accomplished by grasping the teats (often pronounced 'tits') in the hand and expressing milk by either squeezing the fingers, progressively, from the udder end to the tip or by squeezing the teat between thumb and index finger then moving the hand downward from udder towards the end of the teat. This is repeated, using both hands for speed. Both methods result in the milk that was trapped in the milk duct being squirted out the end into a bucket that is supported between the knees (or rests on the ground) of the milker, who usually sits on a low stool.

Traditionally the cow, or cows, would stand in the field or paddock while being milked. Young stock, heifers, would have to be trained to remain still to be milked. In many countries the cows were tethered to a post and milked. The problem with this method is that it relies on quiet, tractable beasts, because the hind end of the cow is not restrained. In cold countries where cows are kept in barns, at least for the winter if not throughout the year, they are still tethered only by the neck or head, particularly where they are kept in small numbers.

Machine Milking

Milking machines are used to extract milk from cows when the herd is larger than about 4 cows. The milking unit is the portion of a milking machine for removing milk from an udder. It is made up of a claw, four teatcups, long milk tube, long pulsator tube, and pulsator. The claw is a manifold which connects the short pulse tubes and short milk tubes from the teatcups to the long pulse tubes and long milk tubes. Claws are commonly made of stainless steel or plastic. Teatcups are composed of a rigid outer shell (stainless steel or plastic), which holds a soft inner liner or inflation. Transparent sections in the shell may allow viewing of liner collapse and milk flow. The annular space between the shell and liner is called the pulsation chamber.