Difference between revisions of "AY Honors/Shoe Repair/Answer Key"

m (1 revision) |

Revision as of 15:49, 16 May 2012

1. Name at least five essential parts of a shoe and explain their uses.

Sole

The bottom of a shoe, which supports the wearer's foot, is named the sole. It usually consists of several layers, and is usually a separate piece from the upper shoe (though not always, as in the case of wooden shoes).

Insole

The insole is the interior bottom of the shoe, which sits directly beneath the foot. Many shoes have removable and replaceable insoles, and extra insoles are often added for comfort or health reasons. (To control the shape, moisture, or smell of the shoe, for example.)

Mid-sole

The mid-sole is a layer situated between the in-sole and the out-sole, found in some shoes. Often it will provide cushioning and shape to the in-sole.

Outsole

The outsole is the layer in direct contact with the ground. The material of the outsole varies depending on the function, dressiness, and quality of the shoe, but is generally very durable material, since it experiences the most stress. Dressier shoes have leather outsoles; casual or work-oriented shoes have outsoles made of natural rubber or a synthetic imitation. The outsole may comprise a single piece, or may comprise separate pieces of different materials. Often the heel of the sole is rubber for durability and traction, while the front is leather for style. Specialized shoes will often have distinct modifications on this design: athletic cleats have spikes embedded in the outsole to grip the ground.

Heel

Some shoes have a distinctive raised heel; often this is a separate piece from the outsole and can be replaced. Leather was used in the past, and is still used in some performance tennis shoes, but harder materials are usually more desirable. Plastic, rubber, or polymer materials are now also used. Fortified cork is sometimes used in heels or soles so the shoes are lightweight.

Vamp, or upper

Any shoe also has an upper part that separates the foot from the air, and helps hold the shoe onto the foot. In the simplest cases, such as sandals or flip flops, this may be nothing more than a few straps for holding the sole in place under the foot. Closed footwear, such as boots, sneakers and most mens shoes, will usually have a more complex upper.

Laces

A shoelace is a long piece of string or cord that hold a shoe closed. Usually it is attached by being threaded through a series of small holes in the shoe, called eyelets. To aid this, many shoelaces are tipped with small solid plastic bits called aglets.

Tongue

In some shoes and boots the tongue is a flap-like, usually flexible, part that goes underneath the laces.

2. What is the difference between hand-turned soles, Goodyear welt soles, and McKay sewed soles? Which is the easiest to repair?

Hand-turned soles

This type of shoe is built inside-out using a form called a last. A last is a foot-shaped tool, traditionally made of wood. After the uppers are made and stitched together, they are removed from the last, turned right-side-out, and the sole is attached. The sole is of one piece - the topside of the sole serves as the insole, and the bottom side serves as the outsole.

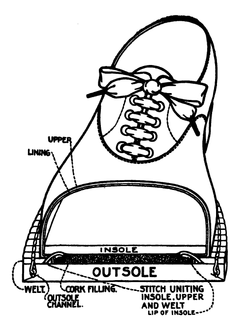

Goodyear welt soles

In a shoe of this type, the uppers, insole, and midsole are stitched to the outsole. This is the most secure way to attach the sole. The insoles are built into the shoe rather than being inserted after the rest of the shoe has been made. The upper is drawn over the sole and held temporarily while a strip of leather (the welt) is stitched to the upper and inner sole. The sole is hand-stitched through the welt to complete the process. This construction allows multiple sole replacements, extending the life of the footwear.

Because the stitching of the outsole is done completely on the outside of the shoe, this type of sole is easiest to repair.

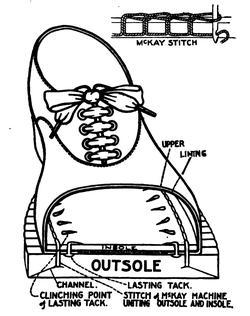

McKay sewed soles

Ten years after the invention of the sewing machine, Gordon McKay introduced a device for machine-stitching a shoe's upper to its sole. In this type of sole, the insole is attached to the upper while it is still on the last using tacks which are clinched over. The outsole is then sewn to the assembly by McKay's machine. The stitching appears on the inside of the shoe, as do the tacks. This type of construction was common for cheap, lightweight shoes.

Curved Needle Machine

The outsole is attached to the upper with a welt. The curve needle machine allows the soles to be stitched through the goodyear welt without the going through the upper so the shoes can be resoled many times without sewing through the uppers.

3. Properly wax the thread, and with two needles or waxed ends, mend a pair of shoes that have rips in them. Use the double-stitch method of sewing.

Shoe repair is best taught by an experienced cobbler. It is not really possible to learn this trade by reading a book - it has to be practiced, and to become proficient takes years. The best approach for meeting this requirement (as well as requirements 4 and 5) is to visit a shoe repair shop as described in requirement 8. Bring a pair of shoes that have rips in them so the cobbler can allow you to practice on your own shoes rather than on his customer's shoes.

Ripped shoes do not necessarily have tears in the canvas or leather, but may have a burst seam. Almost any pair of "throw-away" shoes you still have in your closet will work for this. Depending on the skill you are able to bring to bear on your first attempt, you may end up throwing them away anyhow. Remember that this is a learning process, and your goal is not necessarily to get a wearable pair of shoes out of your effort, but rather, a working knowledge of shoe repair techniques. If you fail on the left shoe, you may succeed on the right. Or you might go through more than one pair of shoes.

It may be possible to build your Pathfinder group's interest in this honor by showing them some shoe repair videos.

4. Satisfactorily half-sole a pair of shoes by nailing the soles on. Make sure the nails are of the proper length.

See requirements 3 and 8 for advice.

5. Fit and attach a pair of rubber heels.

See requirements 3 and 8 for advice. Here's another Youtube video from Upside Down Shoe Repair:

http://www.youtube.com/watch?v=aoUKxBxLCpY

6. What kind of leather should be used in repairing the soles of shoes? How is such leather generally tanned?

Leather used in shoemaking is divided into two categories: upper leather, and sole leather. Upper leather is used for making the uppers, and is thinner, softer, and more pliable than sole leather. Sole leather is generally made from the hide of a fully-grown cow, taken from the thicker parts of the animal's skin. Upper leather is taken from calves, goats, and other smaller animals with thinner skin.

Back when this honor was originally written, leather was usually tanned by soaking it in a bath with tree bark (usually hemlock or oak). An astringent acid would leach out of the bark, and this acid is what would convert an animal skin into leather, in a process known as tanning.

Sole leather was most often tanned using oak bark. Oak-tanned leather has a light, creamy tan color. It is both firm and flexible.

7. Specify at least three factors that should be taken into account in the selection of shoes.

There are many factors to consider when selecting a pair of shoes, including, fit, comfort, function, quality, cost, and even moral considerations. When considering any of these factors, it is incumbent upon the Christian to practice good stewardship.

Fit and Comfort

Possibly the most important factor to consider when selecting a shoe is that it fits properly. Improperly fitted shoes can cause discomfort, soreness, or even injury. Shoes should be comfortable. It is irresponsible to sacrifice comfort for the sake of style, though there are exceptions to this (i.e., the shoe will not be worn for very long and the wearer has no other option, such as serving as the member of a wedding party).

You should have your feet measured every time you buy shoes if they are still growing. Even when they stop growing, it's still a good idea to have them measured occasionally, as their shape may change. There are two parameters that specify the shoe size: length, and width.

Length

Shoe size in the United States and Canada is based on the length of the last, measured in inches, multiplied by 3 and minus a constant. This constant differs for shoes intended for men, women and children.

- [math]\displaystyle{ \mbox{male shoe size} = 3*\mbox{last length}-22 }[/math]

Women's sizes are almost always determined with the "common" scale, in which women's sizes are equal to men's sizes plus 1.5 (for example, a men's 10.5 is a women's 12).

In the less popular scale, known as the "standard" or "FIA" (Footwear Industries of America) scale, women's sizes are men's sizes plus 1 (so a men's 10.5 is a women's 11.5).

- [math]\displaystyle{ \mbox{female shoe size (common)} = 3*\mbox{last length}-20.5 }[/math]

- [math]\displaystyle{ \mbox{female shoe size (FIA)} = 3*\mbox{last length}-21 }[/math]

Children's sizes are equal to men's sizes plus 12.33. Thus girls' and boys' sizes do not differ, even though men's and women's do.

- [math]\displaystyle{ \mbox{child shoe size} = 3*\mbox{last length}-9.67 }[/math]

For the international market, the ISO 9407 standard is used for specifying shoe length.

Width

Some manufacturers offer shoes of different width for the same foot length. Such shoes are then also labelled according to the width or girth of the widest part of the foot (typically measured directly behind the toes with the subject standing on both feet and wearing socks or hose).

In the Mondopoint system, the shoe size label can state in addition to the length also the width of the mean foot for which the shoe is suitable, both measured in millimetres.

A number of other ad-hoc notations for width or girth are also used. Examples include (each starting with the narrowest width):

- AAAA, AAA, AA, A, B, C, D, E, EE, EEE, EEEE

- 4A, 3A, 2A, A, B, C, D, E, 2E, 3E, 4E

- N, R, W

None of these designations are formally standardized. The exact foot width for which these sizes are suitable can vary significantly between manufacturers. The A-E width indicators used by some US and UK shoe manufacturers are typically based on the width of the foot, and common step sizes are 1/4 inch (6 mm) or 3/16 inch (5 mm).

Function

The next consideration when selecting a shoe is the activity to be performed when wearing the shoe. You would not wear high heels on a backpacking trip, nor would you wear flip-flops to a wedding. Different shoes have different purposes, though thankfully, some are multi-purpose. Here is a list of some of the types of shoes available:

- Dress shoes

- Casual shoes

- Athletic shoes

- Running shoes

- Hiking boots

- Climbing shoes

- Paddling shoes

- Work boots

- Steel-toed boots

- Snow boots

- Golf shoes

- Bowling shoes

- Slippers

Quality

If your feet have stopped growing, it makes sense to buy the best quality shoes that you can afford. High quality shoes will not only last longer than cheap ones, they are less expensive in the long run because they will not have to be replaced as often. A low-quality shoe can also make your feet sore or even cause injury by not providing proper arch or ankle support.

If you are buying shoes for a person who is growing quickly, you should still seek a quality shoe, but at this point the goal is match the expected lifetime of the shoe to the amount of time it will fit.

Cost

Cost is also a very important consideration. Some shoes are very expensive, not because of their high quality, but because of the name attached to them. Though high quality shoes are usually more expensive than low-quality shoes, this does not mean that all high-priced shoes are also high-quality.

Moral considerations

In the late 1990's several shoe manufacturers found themselves embroiled in controversy after it was revealed that they were exploiting sweatshop labor in third-world countries. There are many people who boycott various corporations because of such practices, and there are many people who patronize companies that commit themselves to respecting human rights.

8. Spend a minimum of five hours observing shoe repair specialists at their work shop.

You should be able to find a shoe repair shop in the Yellow Pages (or other business directory) under "Shoe Repair." You can also try this web site http://www.vibram.us/repairconsumer/ by Vibram, a shoe repair supplier.

Shoe repair shops are often family-owned businesses, so the chances of speaking to the owner when you enter the store (or call on the phone) are pretty good. It would be better to approach the owner in person rather than calling, as that gives you a better opportunity to present yourself. Wear a class A uniform when you go there to ask permission to observe, and be ready to explain how many Pathfinders will be with you. Let the store owner select a time and date for the five-hour visit. The store owner may also be willing to instruct this honor, so it would be a good idea to make contact before you get started.

Your visit to the work shop will be a good opportunity to meet requirements 3, 4, and 5, but you should probably bring some shoes that need these repairs with you. The owner will certainly not want you experimenting on his customer's shoes! Offer to pay for any materials you use when repairing your shoes.

9. Write or tell the examiners the proper methods of cleaning and caring for shoes.

Keep your shoes looking their best by using a cedar shoe tree. These are foot-shaped blocks of cedar wood that fit inside the shoe. Cedar absorbs moisture and salt which can damage your shoes. Clean shoes right away when they become dirty. There are four basic steps in caring for smooth leather shoes: clean, condition, polish, and weatherproof.

- Clean

First you should lay some newspapers out on your work area and remove the laces from the shoes. Brush the dirt off with a soft brush, and then apply saddle soap or leather cleaner to the shoe with a soft cloth (you can use a shoe shine cloth or an old T-shirt). Work it in, and then start to shine the shoe.

- Condition

Once the shoe has been cleaned, you can apply a conditioner. You can buy cleaners with conditioners in them, but you'll get better results using a separate conditioner. The conditioner is worked into the leather just as the cleaner was, and it helps to moisturize the leather to prevent cracking. In dry climates, you may need to condition your shoes more often.

- Polish

Most of us are familiar with the liquid shoe polish products that come in a bottle with a brush built into the lid. These polishes work well enough, but the polish only barely penetrates the surface of the leather and has to be re-applied frequently. It is better to use a show paste, but best to use a shoe cream. Whichever you choose, you will have to match the color of the product to the color of the shoe. Test in an inconspicuous area to make sure that you have a good color match. Apply shoe cream with a soft cloth and rub it in well. Then let it dry thoroughly. Once dry, you can go over it again with a soft cloth to bring out the shine.

- Weatherproof

If you are more interested in protecting the shoes than in making them look good, you can use beeswax to weatherproof them. Beeswax will change the look of the shoe, but it is most excellent for keeping the water out. This would be a good choice for work or hiking boots. For dress shoes, you will want to use a spray-on product which goes on invisibly. It will protect your shoes from incidental contact with water, but you should not rely on this stuff for wading through puddles.

References

- Curtin Department of Podiatry Hand-turned soles.

- Knappstore.com Explanation of Goodyear welt soles.

- Shoe Links