Difference between revisions of "AY Honors/Alternative Fuels - Advanced/Answer Key/en"

(Updating to match new version of source page) |

(Updating to match new version of source page) |

||

| Line 5: | Line 5: | ||

<noinclude></noinclude> | <noinclude></noinclude> | ||

<!-- 1. Have the Alternative Fuels honor. --> | <!-- 1. Have the Alternative Fuels honor. --> | ||

| − | {{honor_prerequisite | + | {{honor_prerequisite|honor=Alternative Fuels}} |

<noinclude></noinclude> | <noinclude></noinclude> | ||

Revision as of 17:39, 14 September 2021

Skill Level

3

Year

2014

Version

18.02.2026

Approval authority

General Conference

1

For tips and instruction see Alternative Fuels.

2

Hydraulic fracturing is a process that uses a mixture of water, sand, and special chemicals. This solution is injected at a high pressure into a wellbore, a hole that was drilled for natural resource extraction. This process will produce fractures in the rock, thus creating passageways for fluid to collect inside of the drilled hole.

3

Offshore drilling is the process of drilling a wellbore in the seabed. This process is most often used to explore the possible existence of petroleum.

4

The risk of off-shore drilling is high, if measures are not taken to protect the safety of workers and the environment. Recently, the world has witnessed first hand the most devastating accidents ever recorded. Such accidents have a lasting impact on the environment, nearby residents, and tourism. In fact, the combination of these occurrences can have a lasting affect on the economy.

As a result of these accidents, governments have taken steps to address safety concerns by addressing many aspects of offshore drilling, including:

- Environmental Consideration

- Safety Certifications

- Worker Training and Emergency Response

- Well Casing and Cementing

- Equipment for Preventing Blowouts

5

First and foremost, natural gas is extracted from deep within the earth. Large ground drilling machines are used to drill to the area where the gas is located. The drilled hole is then equipped with pipe for the gas to travel through under its own pressure, leading to a central storage location.

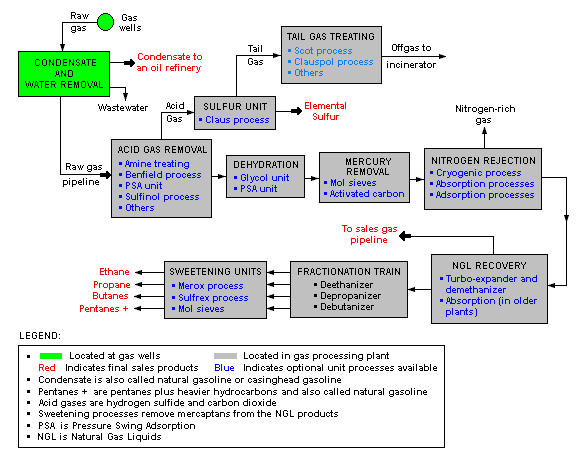

Once the gas has been extracted, it must be processed for use. The first task in the process is to eliminate the acid gases by either an amine or membrane treatment. Residual water after this process is removed. Mercury is then eliminated by passing the gas through a filter of activated carbon. Nitrogen and natural gas liquids are then removed by a low temperature, cryogenic distillation process. The end result is the natural gas that is comes into homes for heating and cooking.

6

6a

In order to produce hydrogen from natural gas, a process called ‘natural gas reforming’ is implemented. The raw form of the natural gas quality is improved using steam at a high temperature.

6b

To generate power from natural gas, the natural gas must be heated and then used to boiled water. The result of the generated steam is forced through impeller turbines causing them to spin. This also causes generator coils to spin, thus producing electricity.

6c

CNG (Compressed Natural Gas) is used to provide power for internal combustible engines. It provides a much cleaner substitute than convention gasoline or diesel fuel. Liquified Natural Gas (LNG) use for commercial trucks and buses is rapidly expanding around the world.

6d

It is used for waste treatment and incineration, glass melting, and food processing. It serves residential, commercial and industrial uses. It also serves as an ingredient for products like paint, detergents, carpets, as well as tires.

7

Fertilizer

Of the many components found in nitrogen fertilizer, ammonia is one that can be produced from cheap raw materials. A combination of natural gas and steam is forced into a large container. The oxygen is then removed from the system by burning natural gas and steam. This process leaves primarily nitrogen, hydrogen, and carbon dioxide. The carbon dioxide is then removed from the system using electrical current.

Plastic

Natural gas can be used to manufacturer plastic materials. For this to be done, the natural gas must be converted to ethane. Heat generated from the conversion process poses a problem and must be removed. Methods have been developed that can heat and cool simultaneously, making the production of plastics from natural gas a viable and more cost effective alternative.

8

Ethanol is produced from any plant or crop source that contains a hefty amount of sugar. It can also be made from starch or cellulose; sources that can be converted to sugar.

Four Step Process

- Crops or plants, used as raw materials are ground up.

- The ground up material results in sugar, which is then dissolved.

- Ethanol and carbon dioxide are produced as a byproduct by introducing bacteria that feed on the sugar.

- The right concentration is obtained by removing the impurities in the ethanol.

9

This is an open group discussion with a unit counselor and/or the instructor teaching the honor.