Especialidades JA/Derbi de automodelos de pino/Respuestas

Nivel de destreza

1

Año

1999

Version

17.11.2024

Autoridad de aprobación

Asociación General

1

2

3

4

4a

4b

4c

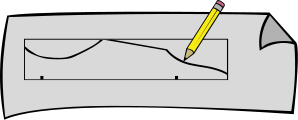

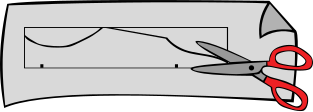

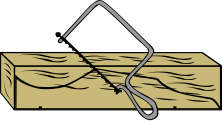

Cutting out your car: Use a 6” coping saw, and a 4” C-clamp. Use a small piece of scrap wood to protect your car from being dented by the C-clamp. Clamp your block to the table, and SLOWLY start your first cut. Hold the saw with both hands, carefully follow the lines you drew on the block of wood. Watch the lines on both sides of the block.

Saw any straight line cuts.

- Shape

- Shape concave surfaces with shaping sticks.

- Filing and Shaping

- You can shape your car even more with different files and “shaping sticks” (wood with sandpaper glued to it.)

- Sanding

- Sand your car so it is reasonably smooth and ready for painting. Sanding the wood smooth can take quite a lot of time.

- Painting

- A great way to paint is to first make the car one solid color using 1” foam brushes. Then use small brushes for fancy details. Always apply thin coats of paint. Thin coats will dry faster. (Optional - Before painting, pound 4 nails into the bottom of your car to make “legs” for the car to stand on. Do not pound the nails too deep. They will be removed when the paint is dry.)

- Wheels, Screws, Axles

- Screw the wheels to the wood dowel axle. Not too tight and not too loose.

- Final Assembly

- After the paint has dried, and the wheels are assembled. Put two (2) small drops of glue in the groove for the wood dowel axle. Press the wheel assembly into place.

4d

- Wheels

- Debur the wheels. Take off the flashing and seam that was produced when the wheel was molded with a 600 grit or better sandpaper. Inside as well as out. Sand any bumps off the wheel with sandpaper. Metal polish will restore the gloss. Be careful not to break any rules your race has regarding wheel modification. (Narrower wheels have less friction and are better, but often disallowed). Don’t sand too much or you’ll create a flat spot. Sand by hand not in the drill. Heat from the high speed of a drill will damage the plastic wheel.

- Polish the axles

- First with a 400 grit if you have a really bad spot. Then a 600 grit, and then a jewelers rouge. Finish off with a chrome/metal polish.

(Optional) Have only three wheels touching the track. Raise a front one slightly. There is less friction with 3 wheels rolling than 4.

The head of the axle should be tapered about 15 degrees so it rubs against the wheel less.

Wax the wheels with furniture polish. Make sure the polish does not contain a solvent of any sort.

Axles

Put the axle in at a downward (5-10 degrees) angle. This provides two benefits. The first is that only the inside edge of the wheel is in contact with the track. This seems to make the car go straighter with less wobble. The second benefit is that the wheel rides to the outside of the axle and doesn’t come in contact with the body. This tip is for experts only. First timers have trouble getting this right.

Axles must be in straight front to back. That is square to the body. True the axles, don’t trust the pre-cut grooves in the block! If you have one, use a drill press to ensure all axles are straight. One of the front and two of the back should be measured to be the same height. Having the axles perfectly parallel to one another is probably the single most important factor affecting the car's speed. If they are not parallel, the car will steer to the left or to the right, eventually hitting the center guide or a wall. This will slow it down, and it makes all that polishing a waste of time.

After pressing in the axles, test the car for crooked wheels. Roll it on the floor. If the wheels are on straight, the car should roll -10 feet in a fairly straight line. Should the car turn left or right, you need to tinker with the axle placement without removing them from the car body, until it rolls straight.

Do not put the axles in at the top of the groove. Put them in at the middle. This lifts the car off the track a bit more and reduces the chance of rubbing on the center strip.

Glue the axles in place. Nothing is worse than having the wheel fall off as you cross the finish line.

Once you match a wheel and axle together with graphite, keep them together. They wear into each other as a matched set.

4e

Leave a lot of wood in the back to put in the weights

Get the weight as close to the 5 ounce limit as possible. Add the last little bit of weight with lead tape from the golf shop. This can be trimmed with scissors at the last minute. Remember, the official scale may not weight the same as yours.

Everyone has an opinion on where to put the weight. One opinion is that the weight needs to be predominantly in the rear so that so that gravity can act upon the weight further up the incline and for a longer period of time. A car with more weight to the rear generally grabs more speed down the slope. Some suggest having the center of gravity at 1 to 1 ½ inches in front of the rear wheels. But be careful not to put too much in the rear or you’ll pop a wheelie.

What kind of weight? Melted lead is dangerous and unnecessary. Tubular weights can be sunk in the sides; flat weights, like those sold in hobby and scout stores can be attached to the car bottom if it is carved in a bit. Incremental weights (with pre-marked grooves) are easier to snap off into the size you need. Some folks just use BBs, nuts & bolts, etc., but these must be glued so that they can not move. No movable weights or mercury allowed.

You can also use the round weights found at the hobby shops and craft stores. This allows you to stick the weights out the back of the car. You can paint them and tell everyone that they are jet engines or tail pipes. That allows you to get the weights as far back as possible.

Keep the weight low on the car and in the center (Left/Right of the car). Put the weight just in front or behind the rear wheels for less wheel chatter.

4f

There are two main types of pine car lubricant, dry and liquid. Dry lubricants are usually either graphite or Teflon, while liquid lubricants are some type of oil. They will both help your car to go faster by reducing the friction between the wheel and the axle. Depending on the rules for your race you may be required to use one or the other so check the rules for your race to see what type of lubricant is allowed. Some races allow either type, some only allow graphite or Teflon, and others will only allow oil.

Either type of lubricant will work, however you should never mix them, if you do the liquid and dry lubricants will form a paste that will make your car slower than it would be without any lubrication at all. If you need to switch from one to the other you should change both your axles and your wheels.

Liquid lubricants have several advantages to dry lubricants, the main one is that they tend to last longer. Graphite usually starts to wear out after a handful of heats while most oils will last for 10-20 heats. So if your race involves more than 4 heats a graphite lubricated car will be at a big disadvantage. Oil if used properly is also usually a faster lubricant than graphite. The disadvantages to using a liquid lubricant are that they are more expensive, and some liquid lubricants can melt the wheels. If you use a liquid make sure that it is approved for use with pine cars.

For most of the liquid lubricants you don't need to use very much. Usually you will just want to use a single drop per wheel. Too much oil will actually cause the car to run slower. To apply the oil put one drop on the axle put the wheel on the axle and spin it, then remove the wheel and wipe the axle with a paper towel to remove any extra oil. You only want a very thin film of oil, this will also keep your car looking nicer.

Dry lubricants are the traditional pine car lubricant. Some people think that graphite works better than the new white Teflon.

Break in the wheels by spinning them with lots of graphite.

Right before check-in, fill the wheel wells with and cover with stickers like a hub cap. You can paint the 1 inch stickers in a contrasting color.

Put a small drop of white glue where the axle goes into the car body and put powdered graphite on it there. That causes friction if the wheel should rub against the car body.

Other than the good polishing of the axles, dump the axles and wheels in a Ziploc bag with some graphite and shake them for a few days prior to the race. That way the wheel and the axles are as slick as can be.

Just a note - graphite is very messy!

5

6

Here’s some tips for when you come to the race.

Have extra axles and wheels on hand. You never know when your car may be the one dropped right before a race.

Have a derby tool kit handy. It should include superglue, sandpaper, a drill, extra screws for your weights, extra weights, a small screwdriver. You many not use it, but it will make you the most popular person at the event.

Transport your car in a shoebox. Dropped cars are unfortunately a too common experience.

Add LOTS of graphite right before check in.

Don’t play with your car. Treat your car with care, at least until Race Day. The more you play with it, the more likely you are to cause it to run more slowly. Running the car along the floor prior to the race will cause it to lose.

Your first goal is to make sure your car can make it all the way down the track.

- Build your car within the rules. If you can’t pass inspection, you can’t race.

- Assure ground clearance. If you add weight to the underside of your car, you should chisel or drill out areas in which to put the weight, so that the weight is “inlaid”. Failure to do this usually results in the car underside scraping the center guide rail.

- Assure vertical clearance. The lane judge should provide plenty of clearance for most any car. However some lane judges/timers have only about 3” clearance, so be sure that your car will fit under that. Crashing your car into the finish line at 120 scale miles per hour is exciting, but not your objective.

7

While building and racing a pinewood derby car your Christian walk may be tested. If someone needed help on their design, did you help? If you are having trouble cutting your own car, did you accept help? Did you clean up your work area so the next person had a clean place to work, or so the staff didn’t have to clean up after you? Did you have to wait a while to use some of the tools? Being patient isn’t always easy.

Jesus was a Carpenter. Jesus may have spent many hours in a wood shop. I wonder if He helped Joseph design, transfer the design, clamp the wood, cut the wood with a saw, file, sand smooth, paint, assemble. I wonder how many tools did Jesus know how to use, that you just used yourself? I wonder...

Note: If you are planning to participate in a conference Pinewood Derby event be sure you use the correct specifications from your conference because some use different specifications than listed above.

Resources:

S&W Crafts Manufacturing

P.O. box 5501

Pasadena, CA 91117

626-793-2443

Pine Car

P.O. Box 98

Linn Creek, MO 65052

Note: Pinewood Derby cars are usually available through the Boy Scout organization.