AY Honors/Cycling/Answer Key 2

1

1a

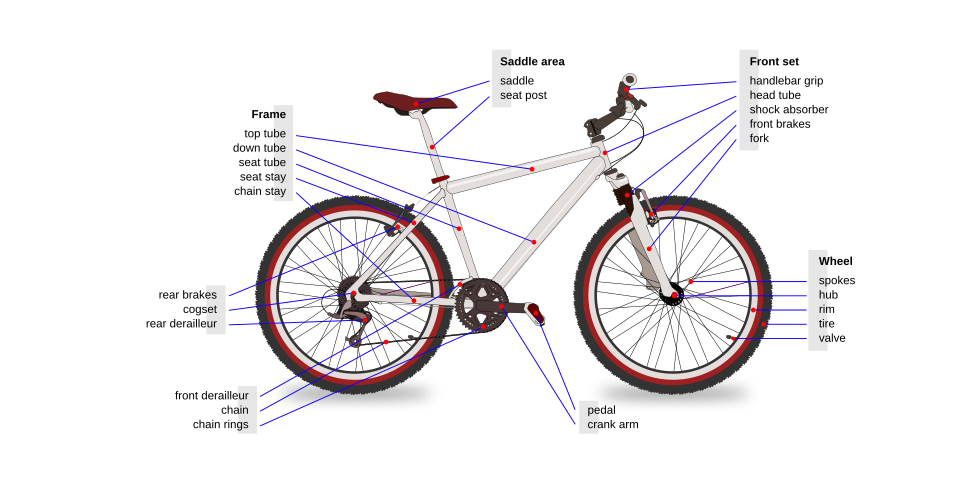

Attachment of crankset to body of bike

1b

Cable connecting the brake lever to the brake mechanism

1c

Lever on handlebar to activate brake. Left side is front brake, right is rear brake

1d

There are up to 10 sprockets of increasing size attached to a hub housing making up a modular cassette. This housing is slipped over an outward extending splined part of the hub. The rear hub is a "freewheel" (ratcheted so the wheel is pulled around when pedaling, but allowing the wheel to spin freely while you coast). The chain is shifted from one sprocket to another by moving the right shifter lever to activate the rear derailleur.

1e

Circular set of links to transfer power from chain ring to cogs of freewheel

1f

Toothed rings attached to crank that hold chain

1g

Lower bar on portion of frame that attaches rear wheel. If there's no second tube on dual suspension bike, it is referred to as a swing arm.

1h

Lever extending from bottom bracket to pedal, transfers power to chain rings

1i

Mechanism for moving chain from one cog to another

1j

Section of frame extending downward from stem to bottom bracket

1k

Cut slot at bottom of front fork or chain stay, designed to accept axle of wheel

1l

Set of rear cogs and idling mechanism

1m

Brake on front fork of bike

1n

Shock absorber on front fork

1o

Horizontal bar attached to the stem with handgrips at the end, to which attach brake levers and shifters

1p

Mechanism in front of frame that connects front fork to stem and handlebars

1q

Section of frame extending downward from top tube to down tube

1r

Center portion of the wheel, to which the spokes attach

1s

Bottom pulley of the rear derailleur, with spring tension to keep chain tight

1t

Threaded receptacle that holds the end of the spoke into the rim

1u

Platform for the foot to press on, attached to crank

1v

Brake on the rear wheel, usually attached to seat stay

1w

Shock absorber for rear tire on dual-suspension bikes

1x

Metal ring with U-shaped cross section, holds spokes on the inside and tire on the outside

1y

The part your butt shouldn't be sitting on when going steep downhill

1z

Support post for saddle, fits into seat tube with mechanism for changing height

1aa

Upper support arm for the rear wheel, not present on dual-suspension bikes with simple swingarm

1bb

Section of frame extending downward from top tube to bottom bracket

1cc

Shifting mechanism for the front derailleur, mounted on the left side of the handlebar

1dd

Shifting mechanism for the rear derailleur, mounted on the right side of the handlebar

1ee

Metal rod that goes through the hub, attaching the wheel to the dropouts of the frame

1ff

Freely rotating "axle" to which the crank arms attach, part of the bottom bracket

1gg

Thick wires joining the hub to the rim, with tension adjusted via a nipple on the rim side

1hh

Piece that attaches the handlebar to the steering tube (headset)

1ii

Lower bar on portion of frame that attaches rear wheel with some form of spring, on full suspension bikes

1jj

Where the rubber meets the road

1kk

Top bar of the bicycle frame

1ll

Stem poking out of rim to inflate tire

1mm

Center of the wheel, to which the spokes attach

2

3

3a

3b

3c

At first glance this appears to be a big task with bits left over after the reassembly. For this requirement all that is intended is the ability to remove both wheels to aid giving the bike a good clean. A more detailed disassembly is required in the advanced honor (cleaning bearings & regreasing). Even in the advanced honor, taking apart a bicycle completely is not intended.

4

WikiBooks Derailleur Adjustment

Rim Brakes

Most bicycle brakes use a lever on the handlebars to pull a cable: that cable draws together a pair of brake arms, pressing the brake blocks (aka pads or shoes) against the rim of the wheel. Friction between the blocks and the rim is what slows the bike down.

First, check that your tires are inflated to their correct state, since any faulty pressures will confuse your efforts.

Check that you have good brake blocks and rims. Rims should be free of corrosion and dirt, and the brake blocks should be appropriate for the rim. Replace worn blocks in pairs.

- To clean steel rims of rust, use wire wool.

- Avoid getting harsh cleaning products on the tires. Degreasers may corrode rubber.

- Leather-faced blocks are best for steel rims.

- Do not get oil, grease or wax on the rims or blocks.

- Excess dirt on rims and blocks will make them wear out faster.

- The rubber brake blocks need to be aligned with the metal rims, but the leading edge of each block should be slightly closer to the rim than the trailing edge. This prevents brake squealing and is called "toeing-in". Use a coin or piece of thin cardboard under the back end of the block as a spacer when adjusting. Some suggest tying an elastic band temporarily to the trailing end of the block instead of a spacer.

- To make the adjustment, slacken the screw holding the block then swing the brake arm in so that the block is pressed squarely against the metal rim, then retighten it with your "toeing-in" device in place. Do one block at a time.

- When both blocks are aligned correctly, decide whether the distance of the blocks from the rims is correct by trying the feel of the brake lever, or by reference to your handbook. V-brakes might need only a 1mm gap, while others will have different settings. If a significant adjustment is needed, it should be done by resetting the cable length, but if a small change will do then use the handlebar barrel adjusters, installed near the brake levers.

- To reset the cable length slacken the brake cable clamp and let the brake side arms relax. Adjust the position of the blocks by moving in both of the side arms until the blocks nearly touch the rims. Retighten the cable in the clamp. This may take a couple of tries to get the blocks close to, but not touching, the rim.

- A fine adjustment may be made with the barrel adjuster. If not on the handlebars it may be near the brake blocks. A locknut keeps the adjustment in place. If the brakes just need a small adjustment, this fine adjustment may be all you need. Screwing the barrel adjusters all the way in before making brake adjustments will allow the widest range of outward adjustments at a later date, though leaving a couple of threads showing on the adjuster will allow a slight inward adjustment of the blocks if it is needed.

- Rotate the wheel to check brake clearance. If it slows too soon then some thing is rubbing. A regular, periodic rubbing when the wheel is spun indicates that the wheel is out of true and needs to be trued. (See: Truing a bicycle wheel.). Sometimes the blocks just need moved out minutely.

- The brake should be centered so that both blocks apply equal pressure to the rim. The method varies:

- For side-pull and center-pull brakes, slacken the central retaining bolt and correct the position of the whole brake assembly.

- For cantilever and V-brake systems, there is a spring-tension adjusting screw on one or both of the arms. Adjust these to bring both arms into balance. Screw it in to move the block further out.

5

Wear a Helmet Bicyclists and bicycle passengers under 18 years old are required to wear helmets.

Always ride with traffic. This is the law. Motorists are not looking for bicyclists riding on the wrong side of the road.

Observe stop signs, signals and basic right-of-way-rules. Bicycle riders on public streets have the same rights and responsibilities as automobile drivers. Cyclists are part of the normal traffic flow and are entitled to share the road with other drivers. Like drivers, bicyclists must yield to pedestrians.

Keep clear of the door zone. Try to ride a door’s width away from parked cars. If you have to ride in the door zone, ride very slowly. You have the right to ride in a traffic lane if it is too narrow to share with a car.

Use hand signals. Hand signals tell motorists what you intend to do. Signalling is a matter of law, of courtesy, and of self-protection.

Keep both hands ready to brake. You may not stop in time if you brake one-handed. Allow extra distance for stopping in the rain and heavy fog, since brakes are less efficient when wet.

Ride a well equipped bike. Be sure your bike is adjusted to fit you properly. For safety and efficiency, outfit it with a bell, rear-view mirror, rack or basket, lights and reflector. Carry a water bottle, bike pump and patch kit. Wear a helmet. Keep your bike in good working order.

Don’t weave between parked cars. Don’t ride out to the curb between parked cars, unless they are far apart. Motorists may not see you when you try to move back into traffic.

Follow lane markings. Make left and right turns in the same way that cars do, using the same turn lanes.

DON'T wear headphones.

DO pull over if you need to use your mobile phone.

6

A helmet is a form of protective gear worn on the head. Traditionally, helmets have been made of metal. In recent decades helmets made from resin or plastic and typically reinforced with Aramid fiber (e.g. Twaron or Kevlar) have become preferred for most applications. Designed for protection of the head in combat, or in civilian life, from sports injuries, falling objects or high-speed collisions.

Helmets are common in the military, construction, mining, and some sports, including American football, baseball,, ski, snowboarding, ice hockey, equestrian sports, motor sports, and rock climbing. Motorcycle helmets and bicycle helmets are compulsory headgear in some jurisdictions; in the United Kingdom only Sikhs are allowed to ride motorcycles without wearing motorcycle helmets. Bicycle helmet compulsion and even strong promotion has been a heated subject of debate among cyclists and scientists since at least the 1990s, lately focusing on alleged net protective effect at the population level.

- Bicycle Helmet Safety Institute : Helmet info.

- Thoughts from Texas Department of Transportation : Wear a properly fitting helmet to reduce the chances of head injury and death. In some places, city or county law requires it.

7

- a. Take three separate 10-mile (16.1 km) rides in different locations.

- b. Take a 50-mile (80.6 km) ride in ten hours or less.

8

8a

8b

References