AY Honors/Model Railroad/Answer Key

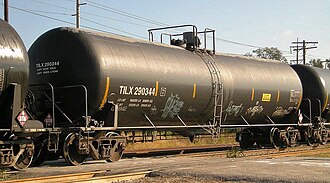

A tank car is a type of railroad rolling stock designed to transport liquid and gaseous commodities. Outside of North America, they are also known as tank wagons or tanker wagons.

History

The tank car was invented in 1865 and was intended to move petroleum in Pennsylvania. Consisting of three open vats attached to a flat car. The problem came as tank car design and liquid cargo types expanded.

Investing in new cars all the time made tank car ownership unappealing to the railroad companies, and so a company was founded: Union Tank Car Company. this company was charged with manufacturing, maintaining and operating, on behalf of the railroads, the tank car fleet.

Tank car timeline

- 1865: Flats with banded wooden tanks mounted on top are employed for the first time to transport crude oil from the fields of Pennsylvania.

- 1869: Cast iron tanks (with an approximate capacity of 3,500 gallons / 13,200 l per car) replace wooden tanks.

- 1888: Tank car manufacturers sell units directly to the oil companies, with capacities ranging from 6,000 gallons to 10,000 gallons (22,700 l to 37,800 l).

- 1903: Tank car companies develop construction safety standards; more than 10,000 tank cars are in operation.

- 1915: A classification system is developed by the tank car industry to ensure the correct match of product being shipped to car type. Some 50,000 tank cars are in use.

- 1920: Welding technology replaces riveting in tank car construction, enhancing the safety of cars.

- 1930: 140,000 tank cars transport some 103 commodities (in addition to oil) to market.

- 1940s: Virtually every tank car is engaged in oil transport in support of the war effort.

- 1950: Pipelines and tanker trucks begin to compete for liquid transport business.

- 1963: The Union Tank Car Company (UTLX) introduces the "Whale Belly" tank car.

Usage

Many variants exist due to the wide variety of liquids and gases that can be transported. Tank cars can be insulated or non-insulated, pressurized or non-pressurized, and designed for single or multiple loads. Non-pressurized cars have plumbing at the bottom for unloading, and may have an access port and a dome, housing various valving on the top. Pressurized cars have a pressure plate, with all valving, and a protective cylindrical housing (dome) at the top. Loading and unloading are done through this opening.

Tank cars are specialized pieces of equipment, with the interior of the car is usually lined with a material to isolate the car's structure from the contents, such as glass. Loading a liquid into a car that is designed to carry something else is unwise and sometimes dangerous. Even after a thorough cleaning, traces of the previous contents may remain, potentially contaminating the next load. Also, loading a tank car with something it is not designed to carry may actually damage the car, for example if the contents are corrosive.

As a result of this specialization, tank cars have always been "one-way" cars. Other cars, like boxcars can easily be reloaded with other goods for the return trip. Combinations of the two types were attempted, such as boxcars with fluid tanks slung beneath the floors. While the car could certainly carry a load both directions, the limited size of the tanks made this style unsuccessful.

Because of their one-way nature, tank cars are simply dead weight half of the time, making them unappealing to major railroads. A large percentage of tank cars are owned by companies serviced by railroads instead of the railroads themselves. This can be verified by examining the reporting marks on the cars. These marks invariably end in X, meaning that the owner is not a common carrier.

Within the rail industry, tank cars are grouped by their interior linings and not by the cargo carried. Food service tank cars are lined with stainless steel, glass or cleanable plastic and they are marked as non-pressurized, insulated cars. Usually these are small and carry around 10,000 gallons. Tank cars carrying dangerous goods are generally made of different types of steel, depending on the intended cargo and operating pressure. They may also be lined with rubber or coated with specialized coatings for tank protection or product purity purpose. They are insulated, usually non-pressurized cars (however, very light petrochemicals or jet fuel cars will be "padded" with nitrogen to remove the air in the vapor space). These cars are larger, around 23,000 gallons. the ends will be doubled to prevent ruptures during accidents. Natural gas, LPG, or ammonia carrying cars are basically 30,000 gallon alloy steel pressure vessels on steel wheels. They have no linings, and are double ended. The whale belly type is giving way to higher, but standard-width cars.

All tank cars undergo periodic inspection for damage and corrosion. Pressure-relief valves and mounts are inspected at every loading. Pressurized cars are pressure-tested regularly to insure the integrity of the tank.

All tank cars operating throughout North America today feature "double shelf" type couplers that prevent disengaging in event of an accident or derailment. This prevents couplers and drawheads from puncturing adjacent tank cars.

Insulated cars (which may also incorporate heating or refrigeration systems) are used when the contents must be kept at a certain temperature. For example, the Linde tank car depicted below carries liquefied argon. Cars designed for multiple loads have internal bulkheads to separate the contents. Each compartment must have separate plumbing and its own dome if so equipped. The added complexity of multiple-load cars means that they make up a small percentage of the tank car population. If two loads must be transported, it is often simpler to use two tank cars instead of a two-load car.

Specialized applications

Milk cars

A milk car is a specialized type of tank car designed to carry raw milk between farms, creameries, and processing plants.

Milk is now commonly clilled before loading, and transported in a glass-lined tank car. Such tank cars are often placarded 'Food service use only'.

Liquid Hydrogen tank car

Template:Main A liquid hydrogen tank car is designed to carry cryogenic liquid hydrogen (LH2). The pressure within the tank is low with a temperature of -130 degrees F or below. The tank is double-walled (vacuum) and insulated with the valves and fittings enclosed within a cabinet at the lower side or end of the car. North American cars of this type are classified as DOT113, AAR204W, and AAR204XT&

Pickle cars

A pickle car was a specialized type of tank car designed to carry pickles. This car consisted of several wooden or metal vats (typically three or four) and was often roofed. Pickles which are preserved in salt brine were loaded through hatches in the roof.

Tanktainers

A tanktainer, also known as a tank container, is a specialized type of container designed to carry bulk liquids as with the liquid hydrogen tanktainer or dangerous goods on standard intermodal equipment. The tank is held within a box-shaped frame the same size and shape as a container.

Torpedo cars

A torpedo car or bottle car is a type of railroad car used in steel mills to haul molten pig iron from the blast furnace to begin the process of primary steelmaking.

The thermally-insulated vessel is mounted on trunnions, and designed to endure extremely high temperatures, as well as keeping the metal in a molten state over extended periods of time. The vessel can be pivoted along its longitudinal axis to empty the pig iron into a furnace (such as a basic oxygen furnace) or crucible.

Vinegar cars

A vinegar car is a specialized type of tank car designed to transport vinegar. The largest such car built was built by Morrison Railway Supply Corporation in 1968. The car's underframe included all of the modern conveniences of freight car design including roller-bearing trucks and cushioning devices built by FreightMaster, while the tank that rode on it, made of Douglas Fir, had a capacity of 17,100 gallons (64,730 liters). The car, in what has been called 'the largest wooden tank car ever built', took 18 months to build.

Vinegar is now moved in ordinary tank cars lined with glass, plastic, or alloy steel.&

"Whale Belly" cars

In the early 1960s, the Union Tank Car Company (UTLX) introduced a series of "whale belly" tank cars which offered increased capacity over the standard cars of the day. Capable of carrying 33,000 gallons (125,000 l) (for example CSOX #31084) to as much as 63,000 gallons (238,500 l) in the case of GATX #96500, which had been conceived as a 'rolling experiment' of sorts. The largest tank car ever placed into regular service, UTLX #83699, was rated at 50,000 (189,200 l) gallons, and is now on display at the Museum of Transportation in St. Louis, Missouri -- first hit the rails in 1963 and remained in service for over twenty years. This behemoth is 89 feet (27 m) in length and weighs 175,000 lb. (79,400 kg) empty; the car, which rides on four two-axle trucks to distribute the additional weight, was used to transport such diverse substances as liquefied petroleum gas (LPG) and anhydrous ammonia.

Representative tank cars

- Carro cisterno de Ferrovie Eritrea.jpg

A carro cisterna (tank car) of the Eritrean Railway (Ferrovia Eritrea, or FE), date unknown. The 2-axle car is 7,000 mm (23 ft) long, and has a 6,650 kg (14,660 lb) load capacity.

- GATX96500.jpg

GATX 96500, the largest railroad 'Whale Belly'-type tank car ever built, rated at 63,000 gallons capacity.

- OP-16236.jpg

Texaco, Inc. (TCX) #723, a single-dome tank car designed for transporting gasoline, passes through Amarillo, Texas on April 4, 1936.

A tank car on display at the Mid-Continent Railway Museum in North Freedom, Wisconsin.

- RR-1331.jpg

The narrow domes on these East Tennessee and Western North Carolina Railroad tank cars mirror the designs of the first all-steel units.

- OP-16233.jpg

This double-dome tank car has two separate interior tanks, which allow different products to be transported in the same car.

- OP-19582.jpg

This unusual three-dome tank car has an oversized center dome.

- OP-20296.jpg

Tank cars such as Canadian National Railway #51860, shown passing through Québec in August, 1937 were designed to transport industrial gases under high pressure.

- Linde-raix708a.jpg

This Linde tank car transports refrigerated liquefied gases and is insulated in order to prevent the contents from evaporating during transport.

A Union Pacific Railroad 'tanktainer' aboard a flatcar.

Borden (BFIX) #520, a restored milk car on display at the Illinois Railway Museum.

A torpedo car used in steel mills to haul molten metal.

- OP-16131.jpg

Two double wooden-tank vinegar cars owned by the Speas Co. wait for their next assignment in Denver, Colorado circa 1965.

See also

References

Sources

- Herron, J. (April 2002). "History Of The Rail Tank Car". e-Train, the online magazine of the Train Collectors Association. http://tcaetrain.org/articles/tickets/tankcar/index.html. Retrieved 2007.

- White, Jr., John H. (1993). The American Railroad Freight Car. The Johns Hopkins University Press, Baltimore, Maryland. Template:Hide in printTemplate:Only in print.

External links

- Rail Whales

- Modern Tank Car Homepage

- Tank car dictionary

- Milk Trains blog for information specific to milk tank cars.

- Liquid Hydrogen Transport by Rail

Template:HydrogenDelivery Template:Freight cars

de:Kesselwagen eo:Cisterna vagono fr:Wagon-citerne ja:タンク車 ru:Вагон-цистерна uk:Вагон-цистерна