Especialidades JA/Reciclaje/Respuestas

1

Recycling involves processing used materials into new products to prevent waste of potentially useful materials, reduce the consumption of fresh raw materials, reduce energy usage, reduce air pollution (from incineration) and water pollution (from landfilling) by reducing the need for "conventional" waste disposal, and lower greenhouse gas emissions as compared to virgin production. Recyclable materials include many kinds of glass, paper, metal, plastic, textiles, and electronics. Although similar in effect, the composting or other reuse of biodegradable waste – such as food or garden waste – is not typically considered recycling. Materials to be recycled are either brought to a collection center or picked up from the curbside, then sorted, cleaned, and reprocessed into new materials bound for manufacturing. In a strict sense, recycling of a material would produce a fresh supply of the same material, for example used office paper to more office paper, or used foamed polystyrene to more polystyrene. However, this is often difficult or too expensive (compared with producing the same product from raw materials or other sources), so "recycling" of many products or materials involves their reuse in producing different materials (e.g., cardboard) instead. Another form of recycling is the salvage of certain materials from complex products, either due to their intrinsic value (e.g., lead from car batteries, or gold from computer components), or due to their hazardous nature (e.g., removal and reuse of mercury from various items). Critics dispute the net economic and environmental benefits of recycling over its costs, and suggest that proponents of recycling often make matters worse and suffer from confirmation bias. Specifically, critics argue that the costs and energy used in collection and transportation detract from (and outweigh) the costs and energy saved in the production process; also that the jobs produced by the recycling industry can be a poor trade for the jobs lost in logging, mining, and other industries associated with virgin production; and that materials such as paper pulp can only be recycled a few times before material degradation prevents further recycling. Proponents of recycling dispute each of these claims, and the validity of arguments from both sides has led to enduring controversy.

2

R.R.R. stands for Reduce, Reuse and Recycle.

This teaches us a set of ideas to help us conserve resources and decrease the mounting piles of waste shipped to landfill sites around the world daily. Nature works in a cycle so that waste becomes food for other living systems and we should do the same.

3

When working with plastics there is often a need to identify which particular plastic material has been used for a given product. Most consumers recognize the types of plastics by the numerical coding system created by the Society of the Plastics Industry in the late 1980s. There are six different types of plastic resins that are commonly used to package household products. The identification codes listed below can be found on the bottom of most plastic packaging.

4

In Spring of 1970, Gary Dean Anderson, as a 23 year old student at the University of Southern California, developed the first recycle logo. As a result, he took home the first place prize of a $2,500 tuition scholarship.

5

6

- Saves Natural Resources - By making products from recycled materials instead of virgin materials, we conserve land and reduce the need to drill for oil and dig for minerals.

- Saves Energy - It usually takes less energy to make recycled products; recycled aluminum, for example, takes 95% less energy than new aluminum from bauxite ore.

- Saves Clean Air and Water - In most cases, making products from recycled materials creates less air pollution and water pollution than making products from virgin materials.

- Saves Landfill Space - When the materials that you recycle go into new products, they don't go into landfills or incinerators, so landfill space is conserved.

- Saves Money and Creates Jobs - The recycling process creates far more jobs than landfills or incinerators, and recycling can frequently be the least expensive waste management method for cities and towns.

7

Aluminum Can

Aluminum - is made from a natural resource called Bauxite Ore. This ore is found in rocks and so must be mined, it. is not a renewable resource which means that once it is gone, we will not have any more. It can take 80-100 years for an aluminum can to decompose (break down and disappear) when it goes to a landfill or dump. Aluminum can be recycled into packaging and containers (beverages, food), building materials, automobile and aircraft construction, appliances (stoves, refrigerators), toys, picture frames, decorative home décor (Bowls, vases, etc), baseball bats, and more. Aluminum is shredded and decontaminated, melted and poured into forms. The entire process takes about 90 days. It can be recycled over and over again forever. Recycling aluminum uses 96% less energy than it takes to produce the same amount of aluminum from raw materials. 95% of air pollutants are eliminated and 100% of solid waste is kept from landfills. Recycling one Aluminum can saves enough electricity to operate a TV for up to 3 hours.

Plastics

Plastics are typically classified by one of seven numbers found inside the chasing arrows, commonly called the recycling symbol. Recycling symbol number identifies the type of plastic used to manufacture the item. However, this does not mean it can be put in your recycling bin for buy back or recycling.

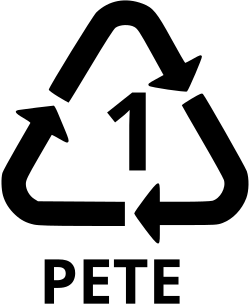

PETE or PET #1

Buy back examples: water bottles and soda bottles (generally see-through and come in different colors). This is the most widely recycled plastic container. Bottles may be color sorted and are ground up and washed. Unlike polyethylene, PET sinks in the wash water while the plastic caps and labels are floated off. The clean flake is dried and often repelletized. Recycled PET has many uses and well established market for this useful resin. By far, the largest usage is in textiles. Carpet companies can often use 100% recycled resin to manufacture polyesther carpets in a variety of colors and textures. PET is also spun like cotton candy to maker fiber filling for pillows, quilts and jackets. PET can also be rolled into clear sheets or ribbon for VCR and audio cassettes. In addition a substantial quantity goes back into the bottle market. All recycling programs accept this plastic. Non buy back examples: cooking oil bottles, peanut butter jars and salad dressing containers should be put into a general recycling bin.

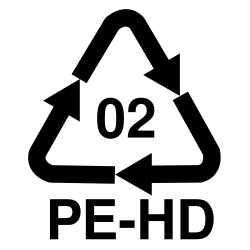

HDPE #2

All curbside recycling programs accept this container if it has a narrow neck. Milk, detergent and oil bottles, toys and plastic bags. HDPE is called natural since that is it's natural color, and it is the most valuable because it can be made into any color when it is recycled. Other products are often packed in brightly colored bottles which are mixed together at recycling plants into mixed color or rainbow bales. Most of this material is later dyed black after it is processed. Recycling HDPE is a pretty simple process. The bales are broken apart and ground into small flakes. These flakes are then washed and floated to removed and heavy (Sinkable) contaminants. This cleaned flake is then dried in a stream of hot air and may be boxed and sold in that form. More sophisticated plastic plants may reheat these flakes, add pigment to change the color and run the material through a pelletizer. This equipment forms little beads of plastic that can then be reused in injection molding presses to create new products. Some end uses for recycled HDPE are plastic pipes, lumber, flower pots, trash cans, or formed back into non food application bottles. Buy back examples: opaque gallon and 2.5 gallon water jugs and opaque juice containers. It takes 1.75 kilograms of petroleum (in terms of energy and raw materials) to make one kilogram of HDPE. HDPE is commonly recycled, and has the number "2" as its recycling symbol. In 2007, the global HDPE market reached a volume of more than 30 million tons. Non buy back examples: cooking oil, peanut butter jars and salad dressing containers should be put into a general recycling bin.

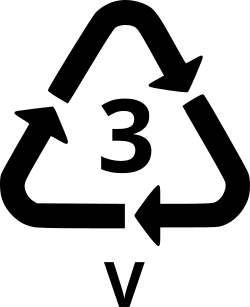

V or PVC

Food wrap, vegetable oil bottles, blister packages. PVC is not typically recycled due to the prohibitive cost of regrinding and recompounding the resin compared to the cost of virgin (unrecycled) resin. Some PVC manufacturers have placed vinyl recycling programs into action, recycling both manufacturing waste back into their products, as well as post consumer PVC construction materials to reduce the load on landfills. The thermal depolymerization process can safely and efficiently convert PVC into fuel and minerals, according to the company that developed it. It is not yet in widespread use. A new process of PVC recycling is being developed in Europe called Texiloop. This process is based on a technology already applied industrially in Europe and Japan, called Vinyloop, which consists of recovering PVC plastic from composite materials through dissolution and precipitation. It strives to be a closed loop system, recycling its key solvent and hopefully making PVC a future technical nutrient.

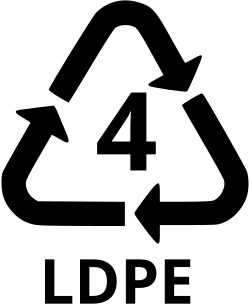

LDPE

Many plastic bags. Shrink wrap, garment bags. It in chemically similar to HDPE but it is less dense and more flexible. Most polyethylene film is made from LDPE which you often see as plastic bags and grocery sacks. This scrap may be clear or pigmented and it is hand sorted and baled at recycling processing plants. Recycling LDPE is very similar to HDPE except special grinders are used to handle the thin films. The films are often washed and repelletized or used directly to make new products. Some end uses for recycled LDPE are plastic trash bags and grocery sacks, plastic tubing, agricultural film, and plastic lumber.

PP

Refrigerated containers, some bags, most bottle tops, some carpets, some food wrap. Polypropylene is often used for food containers, particularly those that need to be dishwasher safe. The melting point of polypropylene is very high compared to many other plastics, at 320°F (160°C), which means that the hot water used when washing dishes will not cause polypropylene dishware to warp. This contrasts with polyethylene, another popular plastic for containers, which has a much lower melting point. Polypropylene is also very easy to add dyes to, and is often used as a fiber in carpeting which needs to be rugged and durable, such as the carpet one finds around swimming pools or paving miniature golf courses. Unlike nylon, which is also often used as a fiber for rugged carpeting, polypropylene doesn't soak up water, making it ideal for uses where it will be constantly subject to moisture. Research is ongoing with polypropylene, as makers experiment with different methods for synthesizing it. Some of these experiments yield the promise of exciting new types of polypropylene, with new consistencies and a different feel from the fairly rigid version we are all used to. These new elastic versions of polypropylene are very rubbery, making them even more resistant to shattering and opening up many different uses for an already pervasive plastic. Polypropylene is not as sturdy as polyethylene, but it has benefits that make it the better choice in some situations. One of these situations is creating hinges from a plastic, such as a plastic lid on a travel mug. Over time, plastics fatigue from the repetitive stress of being opened and shut, and eventually will break. Polypropylene is very resistant to this sort of stress, and is the plastic most often used for lids and caps which require a hinging mechanism. Like many plastics, polypropylene has virtually endless uses, and its development has not slowed since its discovery. Whether used for industrial molds, rugged currency, car parts, or Tupperware, polypropylene is one of a handful of materials the world is literally built around.

PS

Throwaway utensils, meat packing, protective packing. Currently, the majority of polystyrene products are not recycled because of a lack of consumer awareness regarding suitable recycling facilities and collection methods. Expanded polystyrene scrap can be easily added to products such as EPS insulation sheets and other EPS materials for construction applications. Commonly, manufacturers cannot obtain sufficient scrap because of the aforementioned collection issues. When it is not used to make more EPS, foam scrap can be turned into clothes hangers, park benches, flower pots, toys, rulers, stapler bodies, seedling containers, picture frames, and architectural molding from recycled PS. Recycled EPS is also used in many metal casting operations. It can be combined with cement to be used as an insulating amendment in the making of concrete foundations. American manufacturers have produced insulated concrete forms made with approximately 80% recycled EPS since 1993. However, polystyrene recycling is not a closed loop, producing more polystyrene; polystyrene cups and other packaging materials are instead usually used as fillers in other plastics, or in other items that cannot themselves be recycled and are thrown away.

Other (Plastic #7)

This plastic category, as its name of “other” implies, is any plastic other than the named #1-#6 plastic types. OTHER usually layered or mixed plastic. No recycling potential - must be land filled. These symbols are meant to indicate the type of plastic, not its recyclability. Types 1 and 2 are commonly recycled. Type 4 is less commonly recycled. The other types are generally not recycled, except perhaps in small test programs. Common plastics polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS) do not have recycling numbers. Chemical engineers will say that there are many more types and uses for polymers. But most debate in recycling focuses on these seven categories. These containers can be any of several different types of plastic polymers. Some curbside recycling programs accept this container if it has a narrow-neck. Common uses: 3 and 5 gallon reusable water bottles.

Bi-metal

Bi-metal is actually made from steel with a thin plating of tin. You can often tell one of these cans by placing a magnet next to it. If the magnet sticks, the can is most likely bi-metal. Steel and tin, as well as other metals are all natural resources. This means that we have to mine the materials to make them from the ground and that eventually they will be gone. For every ton of steel recycled, 2,500 pounds of iron ore, 1,400 pounds of coal, and 120 pounds of limestone are conserved. Steel can be used for more cans, cars, appliances, and construction materials

Glass

Most ready-to-drink beverages purchased in glass containers are part of the CRV program which requires that the lids be removed from the glass containers. It is important that glass bottles be sorted by these colors: clear, brown and green.

The use of recycled glass as aggregate in concrete has become popular in modern times, with large scale research being carried out at Columbia University in New York. This greatly enhances the aesthetic appeal of the concrete. Recent research findings have shown that concrete made with recycled glass aggregates have shown better long term strength and better thermal insulation due to its better thermal properties of the glass aggregates. Mixed glass waste streams can also be recycled and converted into an aggregate. Mixed waste streams may be collected from materials recovery facilities or mechanical biological treatment systems. Some facilities can sort out mixed waste streams into different colors using electro-optical sorting units.

Many cities do curb-side recycling, meaning that they collect household recyclable waste on a weekly or bi-weekly basis that residents set out in special containers in front of their homes. Apartment dwellers usually use shared containers that may be collected by the city or by private recycling companies which can have their own recycling rules.

In some cases, glass is specifically separated into its own container because broken glass is a hazard to the people who later manually sort the co-mingled recyclables. Sorted recyclables are later sold to companies.

In 1971, the state of Oregon passed a law requiring buyers of carbonated beverages (such as beer and soda) to pay five cents per container as a deposit which would be refunded to anyone who returned the container for recycling. This law has since been copied in nine other states including New York and California. The abbreviations of states with deposit laws are printed on all qualifying bottles and cans. In states with these container deposit laws, most supermarkets automate the deposit refund process by providing machines which will count containers as they are inserted and then print credit vouchers that can be redeemed at the store for the number of containers returned. Small glass bottles (mostly beer) are broken, one-by-one, inside these deposit refund machines as the bottles are inserted. A large, wheeled hopper (very roughly 1.5m by 1.5m by 0.5m) inside the machine collects the broken glass until it can be emptied by an employee. \

All glass containers can be recycled.

Steel

The familiar "tin" can has been part of our society for more than a century. Steel cans package a variety of products, including fruits, vegetables, soups, sauces, meats, condiments, juice, pet food, cleaning products, paint, shoe polish, adhesive bandages, coffee and even cookies. Steel cans are also something else -- recyclable. And they have the potential to be recycled over and over again into new steel products.

8

Uncoded Plastics are plastic consumer goods not identified by code numbers and are not usually collected. Plastic tarps, pipes, toys, computer keyboards, and a multitude of other products simply do not fit into the numbering system that identifies plastics used in consumer containers. There are actually thousands of different varieties of plastic resins or mixtures of resins. These are developed to suit the needs of particular products. There is limited recycling of some of these specific plastic products in truckload quantities from industrial sources. No one has entered the business of collecting a variety of these plastics in small quantities.

9

California, Oregon, Hawaii, Massachusetts, Iowa, Vermont, Maine, Connecticut, Delaware, New York, Michigan, Wisconsin, Illinois and New Mexico. However, all 50 states have some sort of recycling program.

Canada, United Kingdom, Ireland, Netherlands, Jamaica, New Zealand, Germany, China, Japan, Vietnam, Bermuda, Poland, Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Israel, Iceland, Italy, Latvia, Liechtenstein, Lithuania, Luxembourg, Malta, Norway, Poland, Portugal, Philippines, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, India, Australia, Thailand, Taiwan, Mexico, Africa, South Korea and South America

10

11

12

13

14

14a

Turn a plastic bottle into something useful -- a bird feeding station where your kids' feathered friends can feast. Add this to your list of easy science activities for kids as one that shows a positive purpose for recycling. You'll need to help the kids with cutting the bottle.

What You'll Need:

- Plastic 2 liter bottle (without a base cap)

- Blunt scissors

- Nail

- 12-inch wood dowel

- Strong cord

- Birdseed

Procedure:

- Soak the bottle in warm water to remove the label.

- Make sure an adult helps use a nail to carefully poke a hole in each side of the plastic bottle near the bottom for the perch. The holes need to be large enough to fit the dowel.

- Make a U-shaped cut 2 inches above the perch hole on each side of the bottle. Bend each cut area outward like a little awning.

- Punch two holes just under the top rim of the bottle for the hanger.

- Thread a piece of strong cord through the top holes to hang the feeder.

- Insert the dowel through the perch holes.

- Fill the feeder with birdseed, and put the cap back on the bottle.

- Hang the bird feeder outside, and watch the birds eat.

14b

Turn a plastic bottle into something useful -- a bird feeding station where your kids' feathered friends can feast. Add this to your list of easy science activities for kids as one that shows a positive purpose for recycling. You'll need to help the kids with cutting the bottle.

What You'll Need:

- Plastic 2 or 3 liter bottle (without a base cap)

- Blunt scissors

- Nail

- 12-inch wood dowel

- Strong cord

- Homemade Nectar (Hummingbird Food)

Procedure

- Soak the bottle in warm water to remove the label.

- Make sure an adult helps use a nail to carefully poke a hole in each side of the plastic bottle near the bottom for the perch. The holes need to be large enough to fit the dowel.

- Make a U-shaped cut 2 inches above the perch hole on each side of the bottle. Bend each cut area outward like a little awning.

- Punch two holes just under the top rim of the bottle for the hanger.

- Thread a piece of strong cord through the top holes to hang the feeder.

- Insert the dowel through the perch holes.

- Boil 1 part granulated sugar to 4 parts water.

Example: 1/4 cup of sugar to 1 cup water

IMPORTANT: Be sure to let it cool before pouring into hummingbird feeder. Fill the feeder with homemade hummingbird food, and put the cap back on the bottle. - Hang the bird feeder outside, and watch the birds eat.

14c

Turn a plastic water bottle into a decorative lighthouse -- just the thing to brighten up a rainy summer day.

Materials

- 1.5-liter sport water bottle

- Craft knife

- Aluminum foil

- Red acrylic paint

- Black tape

- Play-Doh or clay

- Flashlight

- White craft foam

- Clear packing tape

Total Time Needed: 1 Hour

Instructions

- Use a craft knife (adults only) to cut the bottle in half. Glue aluminum foil inside the cone-shaped portion of the top half (this creates a reflective dome), then use red acrylic paint to coat the outside of the foil-lined section.

- When the paint is dry, apply 3-inch vertical strips of black tape, spaced evenly, around the unpainted portion of the bottle top.

- In the bottom half of the bottle, pack a baseball-sized ball of Play-Doh or clay. Stand a flashlight upright in the clay and press down to secure it in place. Cut a notch down from the bottle's edge to allow access to the flashlight's switch, as shown.

- Next, wrap an 11 1/2- by 10-inch sheet of white craft foam around the bottom half of the bottle (the foam will extend about 4 inches above the bottle) and note approximately where the flashlight switch opening is. Remove the foam and cut out a switch opening. Re-wrap the foam around the bottle and secure the overlapping ends with clear packing tape.

- Finally, fit the cut edge of the bottle top just inside the foam sleeve and securely tape the foam to the bottle with colored tape.

14d

An ocean in a bottle is fairly quick and simple to make. Since "quick & simple" is my middle name, this project was one of my favorites as a kid. Five minutes' work will yield an attractively hypnotic "ocean." It's also a fun use and a second chance for an old plastic bottle.

Things You'll Need:

- plastic bottle

- water

- food coloring

- oil

Instructions

- Once you have your materials, remove the label from the bottle. You may need scissors for this. Or not. Next, fill the bottle about half way up with water and decide what color you want it to be. I was out of red and yellow, so I settled on a teal hue (two drops green, three blue). Add the food coloring and give the bottle a light swirl to mix.

- Here's where that funnel is going to come in handy. Slowly fill the rest of the bottle with your oil. The funnel with prevent the oil from getting all over the outside of your bottle and rendering it hopelessly slippery (I know from experience). Come as close to the top as possible without spilling.

- Now to seal in the goodness. Basically you're just going to screw on the cap as tight as you can. I put some glue on the threads of the bottle before closing as added insurance. You can also wrap some electrical/duct tape around the cap as further protection against leaks if you feel so inclined.

15

15a

15b

15c

15d

http://christianteens.about.com/od/understandingyourbible/qt/ScriptureEnvironment.htm includes a long list of verses.