AY Honor Woodworking Answer Key

1

1a

Lumber comes from trees, so in order to get lumber, a tree must be cut down. Before a tree can be cut down, it must be grown. Many areas are managed forests, where once the trees have been harvested for lumber, new trees are planted to take their place. Doing so make lumber a sustainable resource. The science of growing trees is called forestry.

1b

Harvesting of trees is the practice of cutting them down in order to convert them into lumber. There are several approaches to this, including clear cutting and selective cutting.

When a forest is clear cut, all woody plants are removed. The larger ones are cut into 16' sections and used for making lumber. Contrary to popular belief, clear cutting can actually be beneficial to the forest, as it simulates the effect of a natural forest fire. The trees that are planted in the clear cut will receive more light, and thus produce more lumber more quickly. However, the clear cut should be replanted with the same species of trees that were harvested from the area. Clear cutting is often done during a season on several small tracts of land in a larger forest. This staggers the harvest so that it can be more easily sustained over long periods of time.

Selective cutting is the practice of only removing mature trees from a forest. This has a lesser impact on the forest, but it takes longer to produce lumber and it is more labor intensive than clear cutting. Selective cutting preserves other aspects of the forest though, including its beauty, and its role as a wildlife habitat.

1c

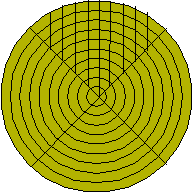

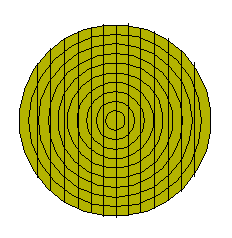

Milling lumber is the process of sawing logs into boards. This is usually done at a saw mill. There are many ways to cut a log into boards, and the method chosen affects the quality of the lumber and the amount of lumber that can be obtained from the log. Quarter sawing produces the highest quality lumber, but it does not produce as much lumber as other methods (such as flat sawing). In quartersawn lumber, the log is first divided into quarters, and then each plank is sawn from that such that the growth rings go through the plank perpendicular to the plank's face.

In flat sawn lumber, All the cuts are made in the same direction. Thus, the growth rings penetrate the board at many different angles. This method of cutting produces the most lumber from a log, but that lumber will be far more susceptible to warping and cupping.

1d

Curing and Seasoning lumber are two words for the same process. It is the process of drying lumber after it has been milled. When timber is first cut, over 50% of its weight is water. As the lumber dries, it changes shape. If it is dried unevenly, it will warp, twist, and crack (cracking is also called "checking"). This is because as the lumber dries, it shrinks. If it dries unevenly, it will also shrink unevenly. To season lumber, it must be allowed to dry evenly. There are several ways to accomplish this, but the two most common are air drying and kiln drying. After the lumber is milled into rough boards, it is stacked horizontally in layers. Each layer is separated by "stickers" which are small pieces of wood about an inch thick, an inch or two wide, and as long as the stack is deep. Stickers are placed on the floor first, and the first layer of lumber is stacked on top of it. More stickers are placed on top of the first layer directly above the stickers on the floor, and another layer of lumber is placed on them. This is repeated until there is a large stack of lumber. Separating the lumber like this allows air to circulate evenly, and thus, the lumber will dry evenly. Kiln dried lumber is stacked in a kiln (a type of oven) in the same way as air dried lumber.

1e

The quality of lumber is widely variable. The difference between the wood suitable for making shipping crates and pallets and the wood suitable for making furniture and toys is fairly large. Grading lumber is the process of assigning a quality figure to it - not unlike grading a school paper or a test. Lumber is graded based on the poorest side of the lumber, and on the yield the lumber is expected to produce (that is, how much of the wood can be converted into boards verses how much will be thrown away).

There are four basic grades of lumber, and even these grades have sub-categories. The basic grades are listed here from the highest quality to the lowest quality:

FAS is short for "Firsts and Seconds." Lumber of this grade is at least 83% clear (free from all defects such as stains, splits, worm holes, knots, etc.) on its poor side.

No. 1 Common is the next grade of lumber. It is often used in furniture making. It must be 67% clear on its poor side.

No. 2 Common must be at least 50% clear on its poor side. It is often used in cabinet making and in millwork (molding, baseboards, and other trim). This grade of lumber is excellent in applications that will be finished with paint (as opposed to a natural finish).

No. 3 Common is the lowest grade of lumber. There are two sub-categories called 3A and 3B. 3A must be at least 33% clear, while 3B must be at least 25% sound (rather than clear). 3A is often used for flooring, while 3B often used for making pallets and crates.

References:

[http://www.woodweb.com/knowledge_base/Understanding_Hardwood_Lumber_Grading.html Understanding Hardwood Lumber Grading]

1f

Once lumber has been milled and cured, it is sized. There are three common methods of sizing lumber. The first and most common is dimensional. The most well known of the dimensional sizes is the 2 by 4 (2x4). Other sizes include the 2x6, 2x8, 4x4, etc. Before a 2x4 is sized, it is 2 inches thick and 4 inches wide. The lumber is then planed so that the edges are smooth and the thickness is even. The planing process removes about a half inch of lumber, so the finished 2x4 is really 1.5 inches thick by 3.5 inches wide. It is still called a 2x4 though, because that's much easier than calling it a 1.5 x 3.5.

The second sizing method is known as quartering. Rough sawn lumber is sized in quarter inch increments. A one inch thick, rough sawn plank is called four-quarter, and this is written as 4/4. Rough sawn lumber is also available in 5/4, 8/4, and 10/4 sizes. These are 1.25", 2", and 2.5" thick respectively.

The third sizing method is the board foot method. A board foot of lumber is one inch thick, 12 inches wide, and 12 inches long. In other words, a board foot of lumber contains 144 cubic inches of wood. Even if the plank is not 12 inches wide or one inch thick, it is still sold by the board foot. One way to calculate how many board feet are in a plank is to first calculate the number of cubic inches (width times thickness times length, all in inches) and then divide that by 144.

2

Pine is the most commonly available wood in North America. Its primary advantage is that it is relatively cheap. This is because it grows rather quickly. Another characteristic of pine is that it is soft. This can be both an advantage and a disadvantage. The advantage of a soft wood is that it is easy to work. The disadvantage is that it can break easily; delicate joinery that works fine in hardwoods will not hold up in pine. Most dimensional lumber (i.e., 2x4's) is made from pine.

Cedar is a beautiful softwood often used for paneling. Because it is also rather aromatic (and its wonderful smell is purported to repel moths), it is most often used for lining closets. It is also a very light wood, so it is used in applications where weight is a concern (such as in the hulls of wooden canoes). The color difference between the sapwood and the heartwood is quite pronounced, and this effect can be exploited for a stunning visual effect. Cedar is also naturally rot-resistant, so it is commonly used as a decking material, or in other outdoor applications. It was once commonly used for making wooden shingles, though it has long since been replaced by modern synthetics which outperform it at a lower cost.

Oak is a very common hardwood. It is a tough wood that holds up well when stressed. It was often used in shipbuilding because of this toughness. Additionally, oak is fairly workable up until it is seasoned. Seasoned oak is very hard, which makes it difficult to cut, bore, plane or drive a nail through. This is an advantage in the finished product, but a disadvantage when trying to make something. When using oak, it is best to use unseasoned wood, and let it season once the object has been made.

Maple is a light colored wood that can be found with highly figured grain. Figured grain is difficult to work with, but makes for a beautiful piece of furniture. Maple is also great for toy making because it does not easily splinter and stands up well to the abuse of even the most destructive of children. Maple is also commonly available, and thus, is relatively cheap for a hardwood.

Ash is fairly easy to work, and like oak, seasons to a very tough and hard wood. It is the preferred wood for making baseball bats, and is also the wood of choice for making gunwales for wooden canoes. In other words, it stands up well to hard knocks.

Walnut is a dark hardwood. Its color is one of its chief advantages, and is probably wood most often "copied" by staining lighter, cheaper woods. Walnut also has figured grain and is fairly hard. It holds detail well, so it can be used in making intricate joints. It is also relatively expensive for a native hardwood.

Cherry is another hardwood that is commonly used in furniture making. Its color starts off as a medium brown and then slowly turns to a dark, beautiful reddish hue over time. It takes a nice finish, and has no need for stain. It is a little cheaper than walnut, but still fairly expensive.

Poplar is classified as a hardwood, but it is relatively soft (though still harder than pine). Because of its softness, it is easy to work.

Elm is a hardwood that is highly resistant to splitting. Because if this, it was the only wood used to make the hubs of wooden wagon wheels. It has a highly figured grain that entwines, and tangles itself in all directions - this is what makes it so difficult to split, but it also makes it difficult to plane.

3

Technically, no power tools are necessary for woodworking - everything can be done with handtools. Power tools can certainly make the job easier, but they are a relatively recent tool to arrive on the woodworking scene.

Handsaws

Handsaws are tools used for cutting wood. Handsaws come in many varieties, including the crosscut saw, rip saw, coping saw, tenon saw, backsaw, and dovetail saw. Each has its own special use. A crosscut saw is used for cutting across the grain of a piece of lumber. A rip saw is used for cutting along the grain. A coping saw is used for making curved cuts. A tenon saw is used for cutting tenons and other fine work. A backsaw is commonly used with a miter box and for small cutting jobs. A dovetail saw is used for cutting dovetail joints.

To use a crosscut or a rip saw, place the board on a supported surface at thigh-height (between the knee and hips). Grip the saw with the right hand (assuming right-handedness) and use the left knee to hold the board in place. Align the right shoulder, arm, and hand so that they are in line with the cut to be made. Begin with light strokes, noting that the saw cuts on the push stroke. As the cut progresses, keep an eye on the line, pulling the blade toward it. If this is to be a "finished" cut, you can score a "V" along the line first with a carton knife, and let the blade ride in the V groove. Score another line along the bottom of the board to prevent tear-out.

A saw is sharpened with a triangle file. The teeth of a rip saw (which cuts along the grain) are sharpened perpendicular to the blade. The teeth of crosscut saw are sharpened at an angle. Try to match the angle already ground into the teeth.

Maintain your saws by keeping them dry and sharp. Many tools (including saws) can be kept in great condition by wiping them down with a cloth and oil (or WD40) after each use. Coping saw blades can be obtained cheaply enough that it is easier to replace them than it is to sharpen them.

Chisels

Chisels can be used for making a variety of cuts in wood, from mortise and tenon joints to dovetail joints. They are often struck with a mallet or a hammer, but sometimes they are pushed by hand (watch for fingers!) to pare a joint or to smooth it. Chisels are also used to remove wood for recessing a hinge. To do this, the outline of the hinge is first scored with a knife, and then the wood is pared away with the chisel.

To cut a mortise, choose a chisel that is as wide as the desired mortise. Mortises should only be cut so that they are parallel to the grain of the wood. Mark the mortise out, and then place the chisel perpendicular to the grain, such that it covers the width of the mortise. Strike it with the mallet. Then move the chisel about an eighth of an inch (2-3mm) farther down the mortise and repeat. Each "bite" of the chisel will go a little deeper. When you get to the end of the mortise, reverse the chisel and take bites in the other direction (still perpendicular to the grain, but heading back toward the other end of the mortise). Continue until the mortise reaches the desired depth. Always cut the mortise first, and then size the tenon to fit.

To sharpen a chisel, hold it at a steady angle and drag it along a whetstone. If you use a grinder, be careful to not overheat the tip of the chisel as this will cause it to lose its tempering. It is better to sharpen them by hand with a whetstone, as it is very easy to overheat the blade with a grinder.

Store chisels in a way that will protect the cutting edge, either by covering them, or placing the edge where it will not come into contact with anything of equal (or greater) hardness than the blade. Like saws, chisels can be wiped down with cloth and oil to keep rust away.

Hand Planes

Adventist Youth Honors Answer Book/Woodworking Tools/Plane

Clamps

Clamps are used to hold a piece of wood in place while it is being worked, or to hold pieces of wood together after gluing them until the glue cures.

Clamps come in many varieties, including C-clamps and furniture clamps. Some say that it is nearly impossible to own too many C-clamps. When using a C-clamp in wood working be careful to not overtighten it. The clamping surface can easily leave a circular impression on the wood. If you need to get it really tight, place a piece of scrap between the clamping surface and your piece.

Furniture clamps (also called bar clamps) often have padded clamping surfaces, so making unwanted impressions on the wood is avoided. These are used for clamping large boards together, usually edge-to-edge.

Clamps can be periodically wiped down with a cloth and oil to keep rust at bay.

Drills, Bits, and Braces

Drills, Bits, and Braces are used for boring holes in wood. A brace and bit is the "old-style" cordless drill. It is hand-powered. The brace holds the bit, and the woodworker's hand cranks it, inducing a rotation in the bit. To drill a clean hole with either a brace and bit or a drill and bit, hold the bit perpendicular to the board and start drilling. You can start a pilot hole with a nail or a punch first to keep the bit from wandering. There are two ways to prevent tear-out when boring a hole. The first method is to support the board and drill into the supporting material. For this to work, the board and its support must be firmly clamped together. The second method can be used if you have a bit with a point that is much narrower than the hole's diameter (such as a spade bit, a brad-point bit, or a bit with a screw-lead). Using such a bit, drill through the material until the tip comes through the other side. Then turn the board over and place the bit in this hole. Continue drilling toward the center.

Power Tools

Power Tools should be used with much care. It is difficult to cut a finger off with a hand saw, but a power saw can do this in an instant, and before the careless operator even feels any pain, a severed finger can drop to the floor. Power tools can greatly speed production of wood projects though, so it's certainly worth having them around. Read the owner's manual carefully before operating any piece of power equipment. Pay special attention to safety features, and do not try to defeat them! Pathfinders below the age of 16 should not use power tools. Remember, power tools are not required for woodworking, they only speed it along.

4

4a

A butt joint is the simplest of all joints, formed by butting two pieces of wood together and then joining them. But because glue will not hold to end grain, it is a joint that must be held together by mechanical fasteners such as nails or screws.

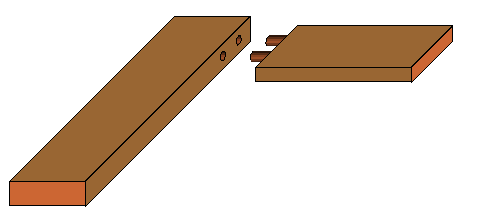

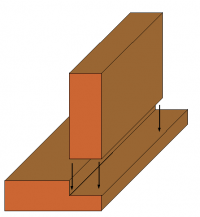

4b

A dado and groove joint is formed by milling a slot (or dado) in one board, and inserting another board into that slot. The width of the dado should be equal to the width of the board that will be inserted into it. The dado is an excellent joint for joining plywood shelves to the upright sides of a bookcase. In this case, the dado should be cut into the side, and the shelf should be inserted into the dado. Such a shelf will support a lot of weight without relying on the strength of a mechanical fastener. A butt joint would likely fail in this situation, with the nail or screw splitting out the top of the shelf.

The dado can also be used in regular lumber as long as the dado runs along the grain - otherwise, any glue used to secure the joint would have to adhere to the endgrain. Plywood presents alternating layers of endgrain and straight grain to all three surfaces of the dado, and there is generally enough straight grain in the joint that gluing it works well. Dado and groove joints can be held together with mechanical fasteners (nails or screws), or without them (assuming enough non-endgrain surfaces in the joint).

4c

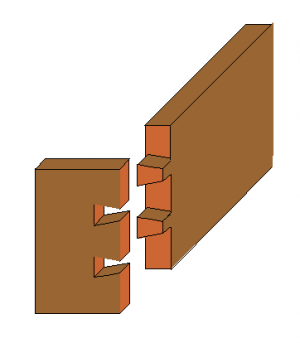

A dovetail joint is made by making "tails" in one piece of wood, and "pins" in the other. In the diagram here, the tails are made in the board on the left, and the pins are made in the board on the right. This joint is very strong and will only pull apart in one direction. It is often used for making drawers and boxes. When making a drawer, the pins are cut in the drawer front, and the tails are cut into the drawer sides. This will prevent the joint from pulling apart when the drawer is opened. A drawer facing is then glued to the front to hide the joint, or the joint can be modified to hide them inherently (these are called "blind dovetails").

To make the joint, cut the tails first. Lay them out with a bevel gauge, and saw from the edge to the line. Remove the waste with a chisel. Then lay this board on top of the board that will have the pins and line them up. Mark the pins with a knife. Then saw the pins with a dovetail saw (or a backsaw). The waste on either side of the pins can be removed with a saw. The waste between the pins can be removed with a chisel or with a coping saw. Assemble the joint to test it for fit, and pare the joint with a chisel if necessary.

In the illustration, the endgrain is colored orange. When gluing a dovetail joint, don't bother applying any glue to the endgrain surfaces. Note that the top surface of the pins (brown) are not endgrain, nor are the surfaces they mate to on the tails.

4d

A dowel joint is formed by drilling holes in the two pieces to be joined, and inserting dowels (small wooden rods) into these holes. The dowels are coated with glue prior to insertion. This is most commonly done with butt joints and miter joints, as the addition of the dowel greatly increases their strength by providing gluable surfaces to the joint.

The most difficult aspect of making a dowel joint is lining the holes up on the two pieces of wood and making sure that the holes go in at a 90 degree angle. This can be done more easily with the aid of a doweling jig. A doweling jig resembles a clamp with a guide hole drilled into it. It is clamped to the board which will eventually accept the dowel, and the hole is drilled by inserting the bit into the guide. A doweling jig will ensure that the hole is drilled at a consistent distance from the board's facing edge and that it is made at a 90 degree angle. The woodworker is still required to ensure that when multiple holes are used (recommended to prevent the joint from twisting), they are drilled the same distance apart.

4e

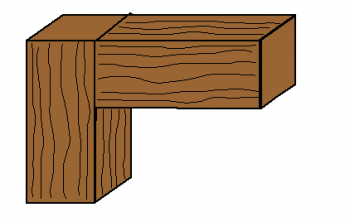

A lap joint is made by overlapping two boards. Wood is removed from the joint so that each board contributes about half of the wood in the joint. Lap joints can be made to join boards at a 90 degree angle (as shown), no angle at all (that is, splice two boards into a longer one), or the two boards can form a cross. This joint is ideal when you need to bring two boards together but keep them in the same plane. It is very strong even without mechanical fasteners as there is a lot of gluable surface area in the joint.

The laps can be cut with either a saw, or a with a saw and a chisel. Large lap joints should be cut with only a saw, but they can be trimmed with a chisel. A dovetail saw or a backsaw works well for both cuts.

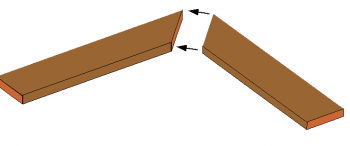

4f

A 90 degree miter joint is formed by cutting the two boards at a 45 degree angle and joining them. The choice of a miter joint is purely aesthetic. Miter joints are easy to cut with a power miter saw, but difficult to cut by hand. A miter box can help, but the angle of the cut must be very nearly perfect, or the joint will either not be 90 degrees, or it will show a gap. The gap can be eliminated by "kerfing in" the joint. Kerfing in a joint is done by clamping the two pieces together and then running a fine-toothed handsaw down the joint. Ideally, the saw should remove wood from both pieces. This procedure can be repeated until the woodworker is happy with the fit, but keep in mind that every time this procedure is performed, the board gets a little shorter. For this reason, it is best to cut the miter joint first, and then cut the piece to length. If both ends of the board are to be mitered, the board should be cut a little long and then tuned to length by kerfing it in.

Miter joints must be reinforced or they will not hold (once again, endgrain comes into play). Usually the pieces are fastened to some underlying structure so that the miter joint is not subjected to stress, nor is it relied upon for structural integrity. In other cases, the joint itself can be reinforced using dowels (as in a dowel joint) or some similar mechanism.

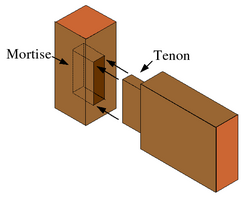

4g

The mortise and tenon joint is a strong joint used to join two pieces of wood usually at a 90 degree angle. The mortise is a hole cut into one of the pieces, and the tenon is shaped to fit snugly into this hole. The tenon is usually narrower than the rest of the piece that it is cut into. The joint may be glued, pinned, or wedged to lock it in place.

The mortise is usually cut first, and its width is equal to the width of the chisel used to cut it (see the section on chisels). The tenon is then sized to fit the mortise, and it is cut with a tenon saw, dovetail saw, or backsaw. The first cuts are made along the grain and are called the cheek cuts. The final cuts are made across the grain and are called the shoulder cuts. The tenon can be pared with a chisel to tune the fit.

4h

A rabbet joint is very similar to a dado joint, except that the groove is cut at the edge of the board. This groove is called a rabbet. It is also sometimes called a rebate. A rabbet joint is often used for joining the back to a cabinet or bookcase. It can be glued, held on with mechanical fasteners, or both. The rabbet can be cut in either or both pieces to be joined.

A rabbet joint can be made with a table saw or a router. It can also be made with a rabbet plane. The blade of a rabbet plane comes all the way to the edge of the tool so that it can remove wood from the corner of the rabbet.

5

5a

Hardboard (also called Masonite) is an engineered wood product made by turning wood chips into long fibers by steaming them. These fibers are then heated and pressed into a solid board. Hardboard is sold in 4'x8' sheets of various thicknesses in the United States. It is an extremely stable material, expanding and contracting very little with changes in temperature and humidity. It is highly homogeneous, having no distinct grain. Because of its lack of grain it behaves very differently as compared to regular lumber.

Hardboard has high bending strength, but has very little structural strength, so it cannot be used in many applications where plywood or regular lumber are more suited. It can be used for building arches, and its strength can be improved by laminating several sheets together. Hardboard is often used as drawer bottoms, or as the back of cabinets, etc.

5b

From Wikipedia, the free encyclopedia.

Particle board (sometimes called chipboard) is a material manufactured from wood particles (for example, wood chips, sawmill shavings, or even saw dust) and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is very dense, heavy, and flat. It is used as a cheaper and less durable substitute for solid wood or plywood. Particle board is very prone to expansion due to moisture.

Particle board should not be used in applications where it is likely to get wet. It is generally not used in furniture making unless it is covered with a veneer (or in inexpensive furniture, a vinyl covering similar to wallpaper). It is not generally finished with stain, varnish, or paint, as aesthetics are not high on its list of characteristics. It is, however used in the hidden portions of woodworking projects such as drawer backs and sides.

5c

From Wikipedia, the free encyclopedia.

Plywood was the first type of engineered wood to be invented. It is made from thin sheets of wood veneer, called plies, which are stacked together with the direction of each ply's grain differing from its neighbors by 90° (cross-banding). The plies are bonded under heat and pressure with strong adhesives, usually phenol formaldehyde resin, making plywood a type of composite material.

A vast number of varieties of plywood exist, tailored for all manner of conditions and uses. Softwood plywood is usually made either of Douglas fir or spruce, pine, and fir. Decorative plywood is usually faced with hardwood, including red oak, birch, maple, lauan (Philippine mahogany) and a large number of other hardwoods.

Plywood production requires a good log, called a peeler, generally straighter and larger in diameter than that required for processing by a sawmill. The log is peeled into sheets of veneer which are then cut to the desired dimensions, dried, patched and glued together to form the plywood panel. The panel can then be patched, resized, sanded or otherwise refinished, depending on the market it was intended to be sold in.

The most common varieties of softwood plywood comes in three, five or seven plies with dimensions of 4 feet × 8 feet. Each ply is 1/8 inch.

A common reason for using plywood instead of plain wood is because plywood is more stable and because it is less prone to change (shrink, twist or warp). Plywood is stronger than particle board and hardboard, and because the outer layers can be made from fine hardwoods, it is often used in furniture making. It is suitable for natural finishing or painting.

6

Unfortunately, some layers of plywood often have knots in them, and the knots fall out before the layers are glued together. This leaves a void. In furniture-grade plywood these voids will be confined to the inner layers. In order to finish the edge of plywood, you can either fill these voids with a wood putty, or you can cover the edges with a band of material - typically, a veneer or a thin strip of wood. Some veneers are made expressly for this purpopse, and they come with an adhesive on one side. By heating the veneer, the adhesive is activated. When it cools, the adhesive bonds to the edge of the plywood. If you plan to use a natural finish, banding works best, because wood putties and wood tend to take natural finishes unevenly. This results in a splotchy finish where the wood putty stands out rather than concealing the defect. Either method can be used if you plan to finish with paint.

7

The first rule of gluing wood joints is that glue does not stick to end-grain. Most woodworking joints were in fact designed to avoid the application of glue to an end-grain surface. Evaluate your joint first, and find two non end-grain surfaces that will come into contact. After making a test fit, apply glue to one of these surfaces. Spread the glue in a thin layer, being careful to not use too much glue. Then clamp the two pieces together. Use enough clamping pressure so that the pieces are held firmly together, but do not use so much force that all the glue is squeezed out of the joint. Once clamped, the pieces should be left alone until the glue sets. Setting times vary from one glue to the next, so read the instructions on the glue container.

8

There are thousands of plans available on the Internet, and many of them can be downloaded for free. Others are offered for a fee. You can also find plans in books and in woodworking magazines (although the magazines tend to have more complex plans). Choose plans that are simple. Although the instructor may be an experienced woodworker, the student is often not. Avoid complicated joints such as dovetails and mortise and tenons. Butt joints, dados, and lap joints are within the reach of a 12 year-old, so steer your Pathfinders to projects that use them. Use lots of pine. Pine is relatively inexpensive, and using it makes it a lot easier to start over. It can be heartbreaking to watch a youngster destroy an expensive piece of wood, and the temptation to salvage it (and thus ruin the project) can be overwhelming. Save complicated projects and expensive hardwoods for after the Pathfinder develops some skill.

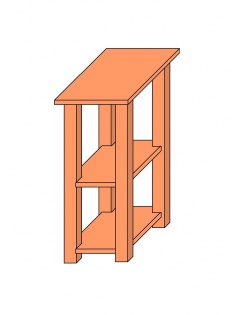

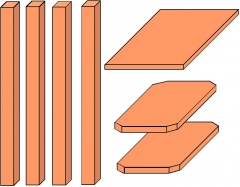

The table described here has been successfully constructed by a group of Pathfinders ranging from Friend to Guide. It is relatively inexpensive, as seven tables can be constructed from a single sheet of plywood, five 8-foot 2x4's, some plywood banding, 28 1/2" #8 woodscrews, seven dozen 1.5" #8 woodscrews, some flat metal brackets, and some 3/8" dowels. Seven is a good number of Pathfinders for two instructors to handle in this honor. More Pathfinders (or fewer instructors) and it is difficult to give them the attention they'll need to execute the project successfully.

Preparations by the Instructor

The instructor should rip the 2x4's into 2x2's, and perhaps crosscut them into 30" lengths (although this can be left to the Pathfinder). These 2x2's will make the legs of the table, and the instructor should make sure the legs are square (that is, each side should be 1.5" or 1.25" wide - the exact measurement is immaterial so long as it is the same on all four sides).

The instructor should also cut the plywood into squares. For seven tables, 14 12"x12" squares (for the bottom and middle shelves) and 7 14"x14" squares should be made (for the tops). These should be made from furniture-grade plywood with a hardwood veneer. Birch veneer works well for this.

Cut the corners

The Pathfinder should mark the corners of the shelves by measuring in 1 inch from each corner and drawing a line across the corner. If the shelves are square, this should make a perfect 45° angle. Do not cut the corners off the 14"x14" tabletop. Save the corners, as they can be used to correct a common mistake (discussed below).

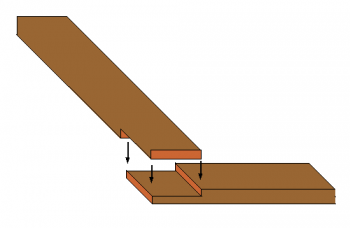

Notch the legs

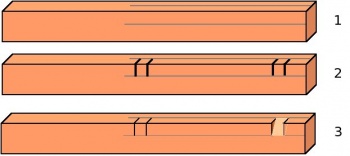

The Pathfinder should then cut two notches in each of the four legs in the three steps shown below:

1: Mark a pencil line one inch from the corner edge of the leg. Do this on two adjacent sides.

2: Measure the width of the plywood and mark where the notches are to be cut with a square. It is better to mark all the legs at the same time, making sure leg bottoms are flush and the notches all line up. Once all the notches have been marked, a notch can be made by cutting two kerfs (saw cuts) through the corner of the leg stopping when the line is reached. You may wish to score the notches with a carton knife before using the saw. Make the first score on the line, holding the knife at a 90° angle. Then make a second score at a steeper angle next to the first score line, but towards the middle of the notch so that the two make a V. Remove wood from the V. This will give you a defined groove for the saw blade to ride in. Pay close attention to both lines when cutting, and be sure to take the width of the kerf into account when making the cuts. The width of the notch should equal the width of the plywood.

3: Use a 3/4" chisel and a mallet to remove the wood between the kerfs. Do not try to remove all the wood at once, but rather, remove a quarter inch on the first three passes, and an eighth of an inch on the final passes. Pay attention to the pencil lines.

Attach the Shelves

The next step is to attach the shelves to the legs. This can be done using dowels or screws. In either case, drill holes into the leg from the outside, centered on the notches. Put the shelf into the notch, and drill a hole into it, using the hole in the leg as a pilot. If using dowels, use the same sized bit (sized for the dowel, 3/8" recommended). If using 1.5" #8 screws, use a 1/8" bit, and then counter sink the hole in the leg 1/2" to 3/4" deep. The screws can be covered with dowels or with wood putty (but don't use wood putty unless you plan to paint).

Correcting Problems

If the notches are too wide, use a chisel to shear a ply off the corners that were removed from the shelves and wedge it beneath the shelf. Note that this is a corrective procedure only - it is much more desirable to cut the notches to the proper width. Using this technique pretty much decides that the table will be finished with paint instead of with a natural finish, but it can still come out looking pretty good. If the notches are not wide enough, use a chisel to widen them a bit. Don't overdo it.

If the notch is too wide to be corrected with a single ply from a corner, discard that leg and start over. That's why the legs are made from 2x4's - you can get six legs from a single 2x4, so each leg will run you about 50 cents (in 2005 anyhow).

Once both shelves have been attached to all four legs, the screws can be covered with dowels (if the screws were countersunk) or with wood putty.

Fasten the Top

Finally, it is time to add the top. The easiest way to do this is by using flat metal brackets. Look for them in the fastener department of the hardware store. Basically, they should be pieces of steel about 3/8 inch wide and 2 inches long, with holes drilled in either end. At least one of these holes should be countersunk, or they should be countersunk on opposite sides of the bracket.

Mill a groove into the top of the leg to accept the bracket. This can be done with a 3/4" spade bit or auger. Drill into the endgrain no more than an eighth of an inch, centered on the leg. Drill a second hole overlapping the first, and make sure the edge of the hole extends over the inside corner of the leg top. If necessary, chisel out a channel between the two holes and then lay the bracket in the channel. The brackets should point towards the center of the table top.

Attach the brackets to the legs using 1.5 inch #8 screws. Make sure that bracket is oriented such that the other hole will be countersunk when a screw is passed through it into the bottom of the tabletop.

Once the brackets are attached, turn the top upside down (choose the best surface for the top), and place the rest of the table on top of it. Center to the best of your ability. The table top is oversized to hide any "unsquareness" of the rest of the table. If the unit will not lay flat on the table top, mark the underside of the tabletop where the screws are touching it. This can be done by daubing a little wood putty on the screw head. Remove the unit and drill a small hole no more than a quarter inch deep into the underside of the table top. It helps to wrap a piece of masking tape around the drill bit at the desired depth so the woodworker can stop when the tape reaches the wood. Replace the unit on the table top again.

Drive screws through the brackets into the underside of the table. Again, use #8 screws, but remember that the table top is only 3/4" thick. Play it safe and use 1/2" long screws.

Finishing

The only thing that remains is to finish the plywood edges and paint (or use a natural finish). Use veneer banding for this, following the instructions on the label. Trim the edges of the veneer off with a carton knife or a chisel. Sand the table and apply two coats of paint or stain and varnish.

If this is a first-time project, the Pathfinder is likely to achieve better results with paint than with stain and varnish. If painting, go back over the piece and cover all screw holes and imperfect shelf joints with wood putty. Woodworking masters eschew wood putty, but it is appropriate for the novice. Wood putty and paint can cover a multitude of woodworking sins!

Leveling

If the table needs to be leveled, place it on a flat surface such as a workbench or a table covered with hard board or cheap plywood. Have one of the longer legs hang off the edge while the other three are in contact with the flat surface. Use a saw to cut the bottom of the offending leg off by laying the blade on the flat surface and drawing it into the leg. This will mar the surface of the table unless a "flush cut" saw is used, but executed properly, it is by far the easiest way to level a table or a chair.

9

The first step in finishing a wood project is to make sure all the surfaces are smooth. This is most commonly done by sanding the surfaces with sandpaper, starting with rougher paper (80-100 grit) and then progressing though successively finer grits (often to 220 grit). Sanding is only necessary if the surface is not already smooth, and some tools (notably planes and cabinet scrapers) will leave a sufficiently smooth surface so that sanding is unnecessary. In fact, sandpaper was patented in the United States in 1834, and woodworking had been going on for millennia prior to that!

The next step in finishing is to remove all dust and dirt from the surface. This can be done by wiping the wood down with a tack cloth, or with a soft cloth which has been wet with mineral spirits. Tack cloth is a soft cloth that has been treated with various finishing compounds (such as mineral spirits and varnish) so that it is slightly sticky or "tacky." It picks up any wood dust it comes into contact with.

Once the surface has been prepared, it can be stained. This can be done by wiping the stain on with a soft cloth (wear vinyl gloves) or with a paint brush. Read the instructions on the can. Staining wood can even out its color. It generally does not fool an experienced woodworker into thinking pine is really walnut or cherry. Staining is optional.

Once the project has been stained (if staining was desired), it can be coated with a finish such as varnish, polyurethane, or tung oil. The purpose of these finishes is to reduce the absorption of moisture. Some finishes do this better than others. Recall that as wood absorbs moisture, its shape changes, so limiting the amount of moisture the project can absorb is a very desirable thing to do.

These finishes are applied again with either a soft cloth (wear gloves!) or a paint brush. You can also buy finishes in spray cans. Several coats are applied, but remember that it is always better to apply several thin coats rather than a few thick ones. Again, read the instructions on the can. Some finishes require that the product dry completely between coats, and others do not.

Make sure the finish is applied in a dust free environment, and do not stir varnish prior to its application, as this will only introduce bubbles which will appear in the finished product. If you do get bubbles, they can be rubbed out between coats with very fine sand paper or with steel wool. The final coat should not be sanded but should rather be polished with a soft cloth.

10

10a

10b

One way to do this is to create a 1:20th scale model that looks much as a real house does before it has siding and a roof put on it. Use balsa wood, a sharp razor blade, and balsa glue.

Create a house plan (keep it simple). You may use typical houseplans that are available in Houseplan magazines and books or create your own.

In order to achieve greatest accuracy, it is recommended that you draw out the scale model to full size grid-paper. Make sure to mark all doorways, windows, entries, and stairs.

Determine what balsa wood sizes will represent each of the standard stud sizes.

Another option is to build a doll house out of wood. These are usually 1:12 scale models, and make a great gifts! Doll House kits are available for sale online.

Purchasing the kit or the balsa wood can be rather expensive. Talk with the hobby shop in your town before beginning! They'll probably help you make the wisest financial decisions. This would be a great project to work on as a class or unit!

10c

Any toys you make can be included in the packages that are often delivered to needy families during the Pathfinder's Can Collecting activity.

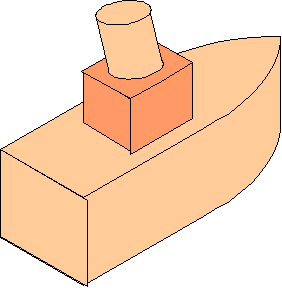

Tugboat

An easy toy to make is a small tug boat. This can be made from two pieces of scrap wood and a dowel - dimensional lumber (2x4's) works great for this. The bottom piece makes the boat's hull and deck, and the top layer makes the cabin. Cut the hull to shape with a coping saw and smooth with a rasp. Before cutting the cabin to its final dimensions, drill the hole for the smokestack. It's a lot easier to drill into a large piece of wood than it is to drill into a small piece. You could also clamp the cabin in a vise for drilling. If desired, bore the hole at a slight angle (about 5°) so the smokestack tilts back. Glue the smokestack dowel into the cabin, and glue the cabin onto the hull. If you use a waterproof glue such as epoxy, the glue joint will be strong enough to not require further reinforcement. Otherwise, reinforce the cabin/hull joint with screws through the bottom of the hull into the cabin. Make sure the screw is well recessed so that it does not scratch the floor (or table) when the tug is dragged around. Optionally, you can drill a small hole straight down through the deck near the front of the boat, and drill a larger hole into the hull from the bottom so that it meets the small hole. Pass a rope through the hole and tie a knot in it to keep it from pulling through the smaller of the two holes. It would be easier to use an eye screw, but this may present a choking hazard to small children. Sand well, and finish with colorful paint.

Car

Another option is to make Pinewood Derby cars. See the instructions in the Pinewood Derby section of the Arts and Crafts chapter of this book.

10d

10e