Difference between revisions of "AY Honors/Leather Craft - Advanced/Answer Key"

m (- Category of AYHAB) |

|||

| (43 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

| − | {{ | + | {{HonorSubpage}} |

| − | + | <section begin="Body" /> | |

| − | {{ | + | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=1}} |

| − | ==2. Show how to punch holes, set snaps, do saddle stitching, and do two types of lacing. | + | <noinclude><translate><!--T:22--> |

| − | ===Punching Holes=== | + | </noinclude> |

| + | <!-- 1. Have the Leather Craft honor. --> | ||

| + | {{honor_prerequisite|honor=Leather Craft}} | ||

| + | <noinclude></translate></noinclude> | ||

| + | {{CloseReq}} <!-- 1 --> | ||

| + | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=2}} | ||

| + | <noinclude><translate></noinclude> | ||

| + | <!-- 2. Show how to punch holes, set snaps, do saddle stitching, and do two types of lacing. --> | ||

| + | ===Punching Holes=== <!--T:23--> | ||

[[Image:Leather_punch.jpg|thumb|200px|Hollow punch with interchangeable tips]] | [[Image:Leather_punch.jpg|thumb|200px|Hollow punch with interchangeable tips]] | ||

There are basically two types of leather punches: the rotary punch and the hollow punch. | There are basically two types of leather punches: the rotary punch and the hollow punch. | ||

| − | ;Rotary punch: The rotary punch looks like a regular paper hole punch, except that it has a "spur" on the end allowing the user to select the size of the hole to be made. | + | ;Rotary punch: The rotary punch looks like a regular paper hole punch, except that it has a "spur" on the end allowing the user to select the size of the hole to be made. This type of punch should not be used when making holes for lacing or sewing. It is more suited to punching holes for a belt, a wrist band, or a snap. |

| − | ;Hollow punch: A hollow punch looks a bit like a small pipe with a sharpened end. | + | ;Hollow punch: A hollow punch looks a bit like a small pipe with a sharpened end. The sharpened end is held against the leather and the other end is then struck with a mallet. The leather should be backed by a piece of soft wood. A small leather disc is removed from the piece and goes up into the punch. The punch usually features a slot in the side so that these discs can be removed. |

| − | ===Setting Snaps=== | + | ===Setting Snaps=== <!--T:2--> |

| − | Before a snap can be set, a hole must be punched in the two pieces of leather | + | Before a snap can be set, a hole must be punched in the two pieces of leather to be joined by the snaps, and located wherever the snaps shall be. It is best to punch both pieces at the same time so that the holes (and thus the two parts of the snap) will line up. Choose a punch that will make a hole which will provide a snug fit for the snap. |

| − | + | <!--T:3--> | |

| + | The snaps themselves consist of four pieces. Two of them are riveted together to make the part of the snap that shows (let's call this the finished half), and the other two pieces are riveted together to make the part of the snap that will be hidden (we'll call that the hidden half). | ||

| − | + | <!--T:4--> | |

| + | Once the holes are punched, insert the finished half of the snap into the hole which will be most visible on the finished piece. | ||

| − | Setting the other half of the snap is | + | <!--T:5--> |

| + | Setting the snap requires the use of a two-part tool specially designed for this purpose. The first part of the tool is a small anvil. The finished side of the snap is placed in the concave surface of the anvil. Note that the snap should still be positioned in the hole punched earlier, and the leather should be situated with its finished-side down. The other half of the snap is then placed on the first half, and the second part of the tool is brought to bear. This part of the tool is similar to a punch, but it is designed to mushroom over the first half of the snap, forming a rivet joint. The tip of the tool is placed on the shaft of the bottom half of the snap, and then the tool is struck sharply with a mallet. Repeated blows may be necessary to form a tight rivet joint. | ||

| − | ===Saddle Stitching=== | + | <!--T:6--> |

| + | Setting the hidden half of the snap is done in the same way. | ||

| + | |||

| + | ===Saddle Stitching=== <!--T:7--> | ||

[[File:Saddle stitch.jpg|thumb|200px|Saddle stitching]] | [[File:Saddle stitch.jpg|thumb|200px|Saddle stitching]] | ||

| − | In saddle stitching, two needles are used, one on each end of the thread. | + | In saddle stitching, two needles are used, one on each end of the thread. One needle is passed through the first hole in the piece and pulled through until there is an equal length of thread on both sides of the hole. Then both needles are passed through the next hole (one at a time). The stitch is pulled tight, and then both needles are passed through the next hole. This is repeated until the seam is finished. To tie off the saddle stitch, pass each needle through only one of the two pieces and tie them together with a square knot on the inside of the seam. |

| + | {{:AY Honors/Knot/Square}} | ||

| + | {{clear}} | ||

| + | |||

| + | ===Lacing=== <!--T:8--> | ||

| + | [[Image:Running_stitch.jpg|thumb|200px|Running stitch]] | ||

| + | ;Running stitch: The running stitch is the simplest type of lacing. Begin by tying an overhand knot in one end. Lay the two pieces of leather to be joined together and punch a row of holes through both thicknesses. Pass the end of the lace through the holes from bottom to top. Pull it tight until the knot meets the hole. Then pass the lace through the next hole from top-to-bottom. The third stitch goes from bottom-to-top, the fourth from top-to-bottom, etc. | ||

| + | {{clear}} | ||

| + | |||

| + | <!--T:9--> | ||

| + | [[Image:Whip_stitch.jpg|thumb|200px|Whip stitch]] | ||

| + | ;Whip Stitch: Punch a row of holes through two pieces of leather as with the running stitch. Tie a knot in one end of the lacing and pass the other through the first hole, from bottom-to-top. In a whip stitch, ''all'' the lacing passes through from the bottom to the top. The lace wraps around the edge of the pieces to get from the bottom to the top. This makes the same pattern the piece of wire in a spiral notebook makes. | ||

| + | {{clear}} | ||

| + | |||

| + | <!--T:10--> | ||

| + | [[Image:Cross_whip_stitch.jpg|thumb|200px|Cross whip stitch]] | ||

| + | ;Cross whip stitch: The cross whip stitch is made like the whip stitch, but the lace passes through every other hole. A second piece of lace does the same thing, but through the holes skipped by the first length of lace. | ||

{{clear}} | {{clear}} | ||

| − | == | + | <!--T:24--> |

| − | + | <noinclude></translate></noinclude> | |

| − | ===Hatchet or Ax Sheath=== | + | {{CloseReq}} <!-- 2 --> |

| − | Follow the same procedure for making an ax sheath as for a hatchet sheath. | + | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=3}} |

| + | <noinclude><translate></noinclude> | ||

| + | <!-- 3. Make a sheath for a hatchet, knife, or ax. --> | ||

| + | ===Hatchet or Ax Sheath=== <!--T:25--> | ||

| + | Follow the same procedure for making an ax sheath as for a hatchet sheath. These instructions custom fit the sheath to the ax or hatchet head. | ||

<gallery> | <gallery> | ||

Image:Making_a_hatchet_sheath_01.jpg|Trace an outline of the hatchet head. | Image:Making_a_hatchet_sheath_01.jpg|Trace an outline of the hatchet head. | ||

| Line 40: | Line 74: | ||

Image:Making_a_hatchet_sheath_11.jpg|Finished product. | Image:Making_a_hatchet_sheath_11.jpg|Finished product. | ||

</gallery> | </gallery> | ||

| − | *Lay the hatchet on a large paper bag and trace an outline the hatchet head. | + | *Lay the hatchet on a large paper bag and trace an outline of the hatchet head. |

| − | *Flip the hatchet over and trace another | + | *Flip the hatchet over and trace another image. The butt end of the hatchet head needs to be spaced such that it is as wide as the hatchet's thickness. The blade ends of the two outlines should touch. |

| − | *Outline a tab on each end of the pattern. | + | *Outline a tab on each end of the pattern. The width of the tab should be half the thickness of the hatchet head. |

*Add a quarter inch to the blade end of the outline. | *Add a quarter inch to the blade end of the outline. | ||

| − | *Draw the flap that will fold around the hatchet head and fasten with a snap. | + | *Draw the flap that will fold around the hatchet head and fasten with a snap. In the photo above, the flap joins the pattern at the end of the blade - this was a mistake. It is better to continue the sweep of the blade's outline, including the allowance for the seam. The other thing to watch for is that the other end of the flap allows for room to wrap around the thickness of the blade at the handle. That end of the flap is longer than the tip end. |

*Cut out the pattern and fold it around the hatchet head, testing the fit. | *Cut out the pattern and fold it around the hatchet head, testing the fit. | ||

*Transfer the pattern to a piece of leather and cut it out. | *Transfer the pattern to a piece of leather and cut it out. | ||

| − | *Fold the rear tabs and stitch them together to make a T-shaped seam. | + | *Fold the rear tabs and stitch them together to make a T-shaped seam. The first stitch is made across the top of the T. A second stitch is made to fasten the two tabs together (forming the vertical part of the T). Sewing the seam will be a lot easier if you make the needle holes with an awl first. |

| − | *Fasten the snaps to the folding tab. | + | *Fasten the snaps to the folding tab. To make sure the snaps are properly aligned and the flap is not too tight, put the hatchet in the sheath (such as it is). Slip a piece of scrap leather between the hatchet blade and the sheath directly beneath the place where the snap will go. Then fold the flap over and punch through both pieces with a hollow punch. The piece of scrap leather will keep you from dulling the punch when you break through the second layer of sheath. If using a rotary punch, punch the snap hole on the flap first, fold it closed, and mark the hole beneath by poking a marker or an awl through the hole. Once the holes are punched, rivet the snap in place. |

| − | *Make a saddle stitch along the blade. | + | *Make a saddle stitch along the blade. Again, the stitching will be a lot easier if you make the holes with an awl. Be sure to pierce both pieces at the same time. Start stitching at the top end of the blade (farthest from the handle). If you start at the other end, you may have difficulty tying off the saddle stitch. Pass the needles through only one piece of leather for the final hole, so that the two ends may be tied together on the inside of the sheath. It is easiest to tie them off if you turn the sheath inside out first. |

*Once the saddle stitching is done, you may opt to place a dot of white glue on the knot (both in the saddle stitch and in the back seam). | *Once the saddle stitching is done, you may opt to place a dot of white glue on the knot (both in the saddle stitch and in the back seam). | ||

| − | *Ta da! | + | *Ta da! Put the hatchet in the sheath and snap it closed! |

| − | == | + | ===Knife Sheath=== <!--T:12--> |

| − | + | <gallery perrow=3> | |

| + | Image:Making a knife sheath 01.jpg|Cut out the leather | ||

| + | Image:Making a knife sheath 02.jpg|Make a strap to hold the handle | ||

| + | Image:Making a knife sheath 03.jpg|Punch holes | ||

| + | Image:Making a knife sheath 04.jpg|Set the snaps and rivet the strap in place | ||

| + | Image:Making a knife sheath 05.jpg|Rivet the sheath closed | ||

| + | Image:Making a knife sheath 06.jpg|Stitch between the rivets | ||

| + | </gallery> | ||

| + | ;Cut out the leather: As with the hatchet/ax sheath, you could lay out a pattern on a paper bag and trace it first. Cut it out and fold it around the knife to test for a good fit. Leave a quarter inch around the perimeter of the blade to accommodate rivets. If satisfied with the results, use that to cut out a piece of leather. If you are not satisfied with the result, you've only lost a paper bag and a little time, so you can do it again. Once you have a pattern you like, trace it onto a piece of leather with a pencil and then cut it out. Use a thick piece of leather for this. A thin piece will be floppy and not hold up well. | ||

| + | ;Make a strap to hold the handle: A knife sheath typically has a strap near the top to hold the handle against the sheath. Without this piece, the knife tends to flop about and may even fall out of the sheath when the wearer bends over. This strap should be a little wider than the snaps you plan to use and long enough to wrap around the knife handle ''at the point where it will be fastened to the sheath''. Most (perhaps all) knife handles have a different girth at different points along their length. It's better to make the strap a little too loose than it is to make it a little too tight. | ||

| + | ;Punch holes: Punch a hole in the center of the strap. Then fold the top of the sheath over on itself to form a loop through which a belt can be slipped. Punch a hole through both thicknesses near the top (make sure you know where you want the strap before punching these holes). Lay the strap on the sheath and then place the knife on top of it, positioned where you want it. Then wrap the strap around the handle and mark it for the snaps. Punch holes for the snaps. | ||

| + | ;Saddle stitch the belt loop: Fold the top of the sheath over on itself and saddle stitch it across the width of the sheath. | ||

| + | ;Set the snaps: Set the snaps following the instructions given above for the hatchet sheath. | ||

| + | ;Rivet the strap in place: Rivet the strap to the sheath. You can buy rivets, or if you feel adventurous (or cash-strapped), you can make your own rivets from nails. To make a rivet from a nail, cut the nail so that it is a little longer than the thickness of the leather (all layers) through which it will pass. The nail should poke out from the leather by an amount equal to half the diameter of the nail shank. Put the nail in place and lay it on an anvil (or on a sledge hammer or on a bench vice's table) with the nail head down. Using the flat face of a ball peen hammer, tap on the cut end of the nail. Then begin tapping on the cut end holding the hammer face at an angle, going all around the edges. Finally, flip the hammer over and use the rounded end (the ball peen) and repeat the process. The end of the nail should mushroom over and flatten out. You can shape the mushroomed portion into a dome with practice. | ||

| + | ;Rivet the sheath closed: Use brass or copper rivets for the sheath. If making your own rivets, use brass or copper nails. Brass and copper are softer than steel, so when the knife blade slides into the sheath and hits the brass or copper rivets, it will not dull the blade as steel rivets would. If you do not rivet the sheath, but merely stitch it closed, the knife may eventually cut through the stitches. Use five evenly-spaced rivets to hold the sheath closed, with the fifth rivet near the tip of the sheath. | ||

| + | ;Stitch between the rivets: Stitch the sheath to keep it from gapping open between the rivets. Locate the stitches closer to the edge of the sheath than the rivets. That way the rivets can protect the stitching from the knife blade. | ||

| − | + | <!--T:26--> | |

| + | <noinclude></translate></noinclude> | ||

| + | {{CloseReq}} <!-- 3 --> | ||

| + | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=4}} | ||

| + | <noinclude><translate><!--T:27--> | ||

| + | </noinclude> | ||

| + | <!-- 4. Complete a figure-carved belt, doing your own tooling. --> | ||

| + | The amount of leather you will need for this will depend on the waist-size of the intended recipient of the belt. The width should be roughly {{units|2.5cm|1 inch}}, but some variability here is OK - just make sure it will fit through the belt loops. | ||

| − | + | <!--T:14--> | |

| + | The length of the belt should be equal to the waist size of the intended wearer plus about {{units|15cm|6 inches}}. {{Units|Ten centimeters|Four inches}} of this excess will be allowed for the end that goes through the buckle, and the remainder will be for the end that attaches permanently to the buckle. Once the belt has been cut out, you can tool it using the standard means. It is not necessary (or even desired sometimes) to tool the entire length of the belt. | ||

| + | <!--T:15--> | ||

| + | When tooling has been completed, the belt can be dyed. Finally, the holes should be punched and the buckle attached. | ||

| + | |||

| + | <!--T:16--> | ||

If you prefer, you could make a guitar strap instead. | If you prefer, you could make a guitar strap instead. | ||

| − | ==5. From your own design, cut from leather, tool, punch, and lace a project such as a case, purse, bag, or an equivalent. | + | <!--T:28--> |

| − | There are many items you use in everyday life and as a Pathfinder that can benefit from having a carrying case. | + | <noinclude></translate></noinclude> |

| + | {{CloseReq}} <!-- 4 --> | ||

| + | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=5}} | ||

| + | <noinclude><translate><!--T:29--> | ||

| + | </noinclude> | ||

| + | <!-- 5. From your own design, cut from leather, tool, punch, and lace a project such as a case, purse, bag, or an equivalent. --> | ||

| + | There are many items you use in everyday life and as a Pathfinder that can benefit from having a carrying case. Here are a few such things: | ||

* Bible | * Bible | ||

* Binoculars | * Binoculars | ||

| Line 78: | Line 145: | ||

* Camera | * Camera | ||

| + | <!--T:18--> | ||

You may prefer to make a garment or accessory: | You may prefer to make a garment or accessory: | ||

* Vest | * Vest | ||

* Hat | * Hat | ||

| + | * Sun visor | ||

* Gloves | * Gloves | ||

* Moccasins | * Moccasins | ||

| + | * Tool belt | ||

| − | ==6. Show six leather items you have made. | + | <!--T:30--> |

| + | <noinclude></translate></noinclude> | ||

| + | {{CloseReq}} <!-- 5 --> | ||

| + | {{ansreq|page={{#titleparts:{{PAGENAME}}|2|1}}|num=6}} | ||

| + | <noinclude><translate><!--T:31--> | ||

| + | </noinclude> | ||

| + | <!-- 6. Show six leather items you have made. --> | ||

You should already have made: | You should already have made: | ||

# a sheath (knife, hatchet, or ax) | # a sheath (knife, hatchet, or ax) | ||

# a belt | # a belt | ||

# an item of your own design | # an item of your own design | ||

| − | # an item you made when completing requirement 4 of the standard level of the [[ | + | # an item you made when completing requirement 4 of the standard level of the [[AY Honors/Leather Craft|Leather Craft]] honor. |

| − | |||

| − | |||

| − | + | <!--T:20--> | |

| + | You will therefore only need to make two more items to meet this requirement. You can make items of your own design, or make items that someone else has already designed, or one of each. It's up to you. | ||

| − | + | <!--T:32--> | |

| + | <noinclude></translate></noinclude> | ||

| + | {{CloseReq}} <!-- 6 --> | ||

| + | <noinclude><translate></noinclude> | ||

| + | ==References== <!--T:21--> | ||

| + | <noinclude></translate></noinclude> | ||

| + | {{CloseHonorPage}} | ||

Latest revision as of 15:52, 14 July 2022

Skill Level

2

Year

1977

Version

19.02.2026

Approval authority

General Conference

1

For tips and instruction see Leather Craft.

2

Punching Holes

There are basically two types of leather punches: the rotary punch and the hollow punch.

- Rotary punch

- The rotary punch looks like a regular paper hole punch, except that it has a "spur" on the end allowing the user to select the size of the hole to be made. This type of punch should not be used when making holes for lacing or sewing. It is more suited to punching holes for a belt, a wrist band, or a snap.

- Hollow punch

- A hollow punch looks a bit like a small pipe with a sharpened end. The sharpened end is held against the leather and the other end is then struck with a mallet. The leather should be backed by a piece of soft wood. A small leather disc is removed from the piece and goes up into the punch. The punch usually features a slot in the side so that these discs can be removed.

Setting Snaps

Before a snap can be set, a hole must be punched in the two pieces of leather to be joined by the snaps, and located wherever the snaps shall be. It is best to punch both pieces at the same time so that the holes (and thus the two parts of the snap) will line up. Choose a punch that will make a hole which will provide a snug fit for the snap.

The snaps themselves consist of four pieces. Two of them are riveted together to make the part of the snap that shows (let's call this the finished half), and the other two pieces are riveted together to make the part of the snap that will be hidden (we'll call that the hidden half).

Once the holes are punched, insert the finished half of the snap into the hole which will be most visible on the finished piece.

Setting the snap requires the use of a two-part tool specially designed for this purpose. The first part of the tool is a small anvil. The finished side of the snap is placed in the concave surface of the anvil. Note that the snap should still be positioned in the hole punched earlier, and the leather should be situated with its finished-side down. The other half of the snap is then placed on the first half, and the second part of the tool is brought to bear. This part of the tool is similar to a punch, but it is designed to mushroom over the first half of the snap, forming a rivet joint. The tip of the tool is placed on the shaft of the bottom half of the snap, and then the tool is struck sharply with a mallet. Repeated blows may be necessary to form a tight rivet joint.

Setting the hidden half of the snap is done in the same way.

Saddle Stitching

In saddle stitching, two needles are used, one on each end of the thread. One needle is passed through the first hole in the piece and pulled through until there is an equal length of thread on both sides of the hole. Then both needles are passed through the next hole (one at a time). The stitch is pulled tight, and then both needles are passed through the next hole. This is repeated until the seam is finished. To tie off the saddle stitch, pass each needle through only one of the two pieces and tie them together with a square knot on the inside of the seam.

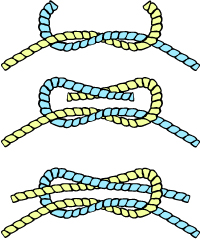

| Square Knot |

|---|

|

Use: Also known as a Reef knot, the Square Knot is easily learned and useful for many situations. It is most commonly used to tie two lines together at the ends. This knot is used at sea in reefing and furling sails. It is used in first aid to tie off a bandage or a sling because the knot lies flat.

How to tie:

WARNING: Do not rely on this knot to hold weight in a life or death situation. It has been known to fail.

|

Lacing

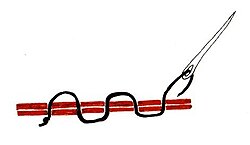

- Running stitch

- The running stitch is the simplest type of lacing. Begin by tying an overhand knot in one end. Lay the two pieces of leather to be joined together and punch a row of holes through both thicknesses. Pass the end of the lace through the holes from bottom to top. Pull it tight until the knot meets the hole. Then pass the lace through the next hole from top-to-bottom. The third stitch goes from bottom-to-top, the fourth from top-to-bottom, etc.

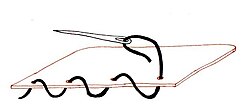

- Whip Stitch

- Punch a row of holes through two pieces of leather as with the running stitch. Tie a knot in one end of the lacing and pass the other through the first hole, from bottom-to-top. In a whip stitch, all the lacing passes through from the bottom to the top. The lace wraps around the edge of the pieces to get from the bottom to the top. This makes the same pattern the piece of wire in a spiral notebook makes.

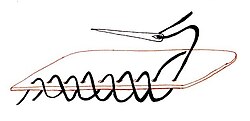

- Cross whip stitch

- The cross whip stitch is made like the whip stitch, but the lace passes through every other hole. A second piece of lace does the same thing, but through the holes skipped by the first length of lace.

3

Hatchet or Ax Sheath

Follow the same procedure for making an ax sheath as for a hatchet sheath. These instructions custom fit the sheath to the ax or hatchet head.

- Lay the hatchet on a large paper bag and trace an outline of the hatchet head.

- Flip the hatchet over and trace another image. The butt end of the hatchet head needs to be spaced such that it is as wide as the hatchet's thickness. The blade ends of the two outlines should touch.

- Outline a tab on each end of the pattern. The width of the tab should be half the thickness of the hatchet head.

- Add a quarter inch to the blade end of the outline.

- Draw the flap that will fold around the hatchet head and fasten with a snap. In the photo above, the flap joins the pattern at the end of the blade - this was a mistake. It is better to continue the sweep of the blade's outline, including the allowance for the seam. The other thing to watch for is that the other end of the flap allows for room to wrap around the thickness of the blade at the handle. That end of the flap is longer than the tip end.

- Cut out the pattern and fold it around the hatchet head, testing the fit.

- Transfer the pattern to a piece of leather and cut it out.

- Fold the rear tabs and stitch them together to make a T-shaped seam. The first stitch is made across the top of the T. A second stitch is made to fasten the two tabs together (forming the vertical part of the T). Sewing the seam will be a lot easier if you make the needle holes with an awl first.

- Fasten the snaps to the folding tab. To make sure the snaps are properly aligned and the flap is not too tight, put the hatchet in the sheath (such as it is). Slip a piece of scrap leather between the hatchet blade and the sheath directly beneath the place where the snap will go. Then fold the flap over and punch through both pieces with a hollow punch. The piece of scrap leather will keep you from dulling the punch when you break through the second layer of sheath. If using a rotary punch, punch the snap hole on the flap first, fold it closed, and mark the hole beneath by poking a marker or an awl through the hole. Once the holes are punched, rivet the snap in place.

- Make a saddle stitch along the blade. Again, the stitching will be a lot easier if you make the holes with an awl. Be sure to pierce both pieces at the same time. Start stitching at the top end of the blade (farthest from the handle). If you start at the other end, you may have difficulty tying off the saddle stitch. Pass the needles through only one piece of leather for the final hole, so that the two ends may be tied together on the inside of the sheath. It is easiest to tie them off if you turn the sheath inside out first.

- Once the saddle stitching is done, you may opt to place a dot of white glue on the knot (both in the saddle stitch and in the back seam).

- Ta da! Put the hatchet in the sheath and snap it closed!

Knife Sheath

- Cut out the leather

- As with the hatchet/ax sheath, you could lay out a pattern on a paper bag and trace it first. Cut it out and fold it around the knife to test for a good fit. Leave a quarter inch around the perimeter of the blade to accommodate rivets. If satisfied with the results, use that to cut out a piece of leather. If you are not satisfied with the result, you've only lost a paper bag and a little time, so you can do it again. Once you have a pattern you like, trace it onto a piece of leather with a pencil and then cut it out. Use a thick piece of leather for this. A thin piece will be floppy and not hold up well.

- Make a strap to hold the handle

- A knife sheath typically has a strap near the top to hold the handle against the sheath. Without this piece, the knife tends to flop about and may even fall out of the sheath when the wearer bends over. This strap should be a little wider than the snaps you plan to use and long enough to wrap around the knife handle at the point where it will be fastened to the sheath. Most (perhaps all) knife handles have a different girth at different points along their length. It's better to make the strap a little too loose than it is to make it a little too tight.

- Punch holes

- Punch a hole in the center of the strap. Then fold the top of the sheath over on itself to form a loop through which a belt can be slipped. Punch a hole through both thicknesses near the top (make sure you know where you want the strap before punching these holes). Lay the strap on the sheath and then place the knife on top of it, positioned where you want it. Then wrap the strap around the handle and mark it for the snaps. Punch holes for the snaps.

- Saddle stitch the belt loop

- Fold the top of the sheath over on itself and saddle stitch it across the width of the sheath.

- Set the snaps

- Set the snaps following the instructions given above for the hatchet sheath.

- Rivet the strap in place

- Rivet the strap to the sheath. You can buy rivets, or if you feel adventurous (or cash-strapped), you can make your own rivets from nails. To make a rivet from a nail, cut the nail so that it is a little longer than the thickness of the leather (all layers) through which it will pass. The nail should poke out from the leather by an amount equal to half the diameter of the nail shank. Put the nail in place and lay it on an anvil (or on a sledge hammer or on a bench vice's table) with the nail head down. Using the flat face of a ball peen hammer, tap on the cut end of the nail. Then begin tapping on the cut end holding the hammer face at an angle, going all around the edges. Finally, flip the hammer over and use the rounded end (the ball peen) and repeat the process. The end of the nail should mushroom over and flatten out. You can shape the mushroomed portion into a dome with practice.

- Rivet the sheath closed

- Use brass or copper rivets for the sheath. If making your own rivets, use brass or copper nails. Brass and copper are softer than steel, so when the knife blade slides into the sheath and hits the brass or copper rivets, it will not dull the blade as steel rivets would. If you do not rivet the sheath, but merely stitch it closed, the knife may eventually cut through the stitches. Use five evenly-spaced rivets to hold the sheath closed, with the fifth rivet near the tip of the sheath.

- Stitch between the rivets

- Stitch the sheath to keep it from gapping open between the rivets. Locate the stitches closer to the edge of the sheath than the rivets. That way the rivets can protect the stitching from the knife blade.

4

The amount of leather you will need for this will depend on the waist-size of the intended recipient of the belt. The width should be roughly 2.5cm![]() , but some variability here is OK - just make sure it will fit through the belt loops.

, but some variability here is OK - just make sure it will fit through the belt loops.

The length of the belt should be equal to the waist size of the intended wearer plus about 15cm![]() . Ten centimeters

. Ten centimeters![]() of this excess will be allowed for the end that goes through the buckle, and the remainder will be for the end that attaches permanently to the buckle. Once the belt has been cut out, you can tool it using the standard means. It is not necessary (or even desired sometimes) to tool the entire length of the belt.

of this excess will be allowed for the end that goes through the buckle, and the remainder will be for the end that attaches permanently to the buckle. Once the belt has been cut out, you can tool it using the standard means. It is not necessary (or even desired sometimes) to tool the entire length of the belt.

When tooling has been completed, the belt can be dyed. Finally, the holes should be punched and the buckle attached.

If you prefer, you could make a guitar strap instead.

5

There are many items you use in everyday life and as a Pathfinder that can benefit from having a carrying case. Here are a few such things:

- Bible

- Binoculars

- MP3 player

- Cell phone

- Eyeglasses

- Toiletries

- Flint and steel

- Notebook

- Daily planner

- Pathfinder pins

- Laptop Computer

- PDA

- Camera

You may prefer to make a garment or accessory:

- Vest

- Hat

- Sun visor

- Gloves

- Moccasins

- Tool belt

6

You should already have made:

- a sheath (knife, hatchet, or ax)

- a belt

- an item of your own design

- an item you made when completing requirement 4 of the standard level of the Leather Craft honor.

You will therefore only need to make two more items to meet this requirement. You can make items of your own design, or make items that someone else has already designed, or one of each. It's up to you.