AY Honors/Printing/Answer Key

1. Know how the following printing devices work:

a. Web press

A web press prints on a continuous paper roll (web). Think of printing newspapers, etc. Sometimes a web press can print on both sides of the paper at the same time, as well as printing in color, and finishing (cutting, folding, punching, etc.)

b. Offset press

An 'Offset press' uses an 'offset' roller which transfer the 'inked image' from the plate to the printing surface of the paper.

Offset printing is a widely used printing technique where the inked image is transferred (or "offset") from a plate to a rubber blanket, then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier on which the image to be printed obtains ink from ink rollers, while the non-printing area attracts a film of water, keeping the non-printing areas ink-free.

See the Wikipedia article on Offset printing for more.

c. Photocopy machine

How a photocopier works (using xerography):

- First, the surface of a cylindrical drum is given an electro-static charge by a high-voltage wire called a corona wire. The drum is coated with a photoconductive semiconductor material, such as selenium or germanium.

- Then the light reflected from the scanned original document is beamed in a narrow band onto the surface of the drum. Only the white areas of the original document reflect light. The reflected light then hits the drum, which is specially conditioned to make it photoconductive. This means that wherever light hits it, the positive charges are conducted away to a ground.

- As a result, the white areas of the picture are now neutral, and the black areas remain positively charged, yielding a latent electrical image on the surface of the drum.

- The toner is negatively charged. Therefore, when it is applied to the drum to develop the image, it is attracted and sticks to the areas that are positively charged, just as paper sticks to a toy balloon with a static charge.

- The toner image is then transferred from the drum onto a positively charged piece of paper.

- The drum is then wiped clean and completely discharged by light, before beginning the process again.

- The toner is a dry powder. If copies were to exit the photocopier covered in dry toner it would easily brush off. Toner usually contains a styrene or polyester resin, and with the application of high heat and pressure it melts and binds (or fuses) to the paper.

d. Letterpress

Think Gutenberg.

Letterpress is probably one of the first printing methods. Individual 'letters' are assembled to form words, sentences, and paragraphs into a form and when finished this is tightened/locked and this form is 'inked' and applied / pressed to the paper resulting in the printed page.

You can also research "letterpress" at Letterpress printing.

2. Know what the reference of pound means in determining the weight of paper.

Basically, it is the weight of 500 sheets (a ream) of paper stock, but not in the cut sizes you find for your printer, etc, but in the 'uncut' size as manufactured.

Requirement #5 of Bookbinding [1] has an answer for 'pound-weight'. Also, there are several lines here [2].

3. Know what the following paper types are used for:

a. Offset

'Offset' paper is an uncoated paper.

b. Bond

'Bond' paper is a high quality paper used for a variety of purposes (like in your computer printer or copier). It's name is derived from the original use of such paper for 'government bonds'.

c. Cover weight

'Cover weight'. Possibly 'cover stock' which is paper generally used for the cover of books, pamphlets, or other soft covered books.

d. Index

'Index' paper. Possibly 'Index Bristol' which is a rather thick paper stock.

3. Tour a print shop or newspaper company. Write a 300-word report or give a three-minute oral report on the steps taken in the printing process that you observed.

- Ah! This is your part.

4. Do some research to learn about the history of printing. Trace the development of printing by learning how printing presses have progressed to the present.

Try this for a starting point:

5. Know the different inks available for printing and their characteristics.

Commercial printing inks.

News Ink: for newspapers and web printing which is fairly soft and flowing.

Regular Offset Inks: for small and large commercial sheet fed presses (for magazines, etc) (heavy flow).

Silkscreen Ink: for like T-shirts, etc. (liquid).

Letterpress Inks: for letterpress (soft flow).

All are oil based. Even soy based inks are still mostly oil. Mostly linseed oil is used.

There are sub-categories of the regular offset inks for ultra violet printing (which lends itself to resist the sun's deteriotion of some colors), plastic printing, and the latest for waterless printing.

(Many thanks to my uncle in the printing ink industry.)

6. Know the meaning of the following terms:

- a. Backing up

- Printing things on the back side of a paper after the front side has already been printed.

- b. Blanket

- A thick rubber mat that transfers ink to the paper on a printing press.

- c. Bleed

- Print that goes all the way to the edge of a sheet as a result of trimming the paper.

- d. Boldface

- Typeface or fontwork that is thicker than normal. For example, the word "Boldface" above compared to here.

- e. Camera ready art

- Camera ready art is art(work) that is ready for the camera to take a 'picture' onto the plates which will 'print' the printed material.

- f. Caption

- Short text describing an image or picture immediately next to the image or picture.

- g. Clip art

- This is graphics and other source material (sometimes in a clip art book) that you 'clip' or cut out and 'paste-up' into 'camera ready' work.

- h. Collate

- Sorting printed material in a precise order.

- i. Color separations

- To print color photos, the pictures must be divided into four colors - red, yellow, blue, and black. These four colors are then printed separately on the same page, with all the other colors being made by combining these four.

- j. Contact print

- Much like in photography, this is placing a negative in direct 'contact' with the camera's plate and then exposing this 'sandwich' for a short time to a light source.

- k. Debossing

- This is the reverse of 'Embossing' where the image is depressed into the paper surface. In embossing, the image is raised.

- l. Embossing

- Imprinting an image by pressing it into the paper forming a raised relief.

- m. Engraving

- This is a printing method which uses a printing plate (or die) which has an image cut into the printing surface. (Die: a stamp used to press an image or design). This is a type of 'Intaglio' printing.

- n. Font

- The appearance/characteristics of the letters that makes up a typeface. Courier, Times Roman, Arial, are examples of different fonts.

- o. Ghosting

- A faint copy of an image appearing on a page where it was unintended.

- p. Intaglio

- Intaglio (pronounced in-TAL-yo) is a printmaking technique in which the image is incised into a surface. Normally, copper or zinc plates are used as a surface, and the incisions are created by etching, engraving, or some other method. To print an intaglio plate, the surface is covered in ink, and then rubbed vigorously with a special cloth or with newsprint to remove the ink from the surface, leaving it only in the incisions. A damp piece of paper is placed on top, and the plate and paper are run through a printing press that, through pressure, transfers the ink from the recesses of the plate to the paper.

- q. Jog

- Aligning the printed material on two adjoining edges. You would do this, for example, so that you can cut the printed material, bind, or, other finishing tasks.

- r. Matte

- A dull, flat ink finish.

- s. Negative

- A reverse-color image. In a black and white negative, areas that are supposed to be white are black, and areas that are supposed to be black are white.

- t. Paste-up

- 'Paste'-ing clip art, words, pictures, onto a page to create what you want the page to look like, resulting in 'camera ready' work.

- u. Register

- To line up a piece of paper for printing so that the printed material is placed in the correct position on the page. This is important especially when printing separate colors in the 4-color process.

- v. Set-off

- Unwanted transfer of ink from the top (printed) side of one sheet to the underside of another sheet after having been printed.

- w. Show through

- When printing on one side of a page can be seen on the other side of the page.

- x. Thermography

- This mostly refers to printing using a special process (ink, dusting powder, and a heat process) to create raised letters on the resulting printed paper. Mostly done on business cards, letterheads, envelopes, invitations.

- y. Water mark

- A light design on a sheet of paper which can be easily seen if the sheet is held up to a light. U.S. currency has a lot of watermarking.

- z. Work and turn

- The process of printing one side of a paper and then flipping it left-to-right and printing the opposite side using the same guide rails.

7. Know the difference between half-tones, duo-tones, and the four-color process.

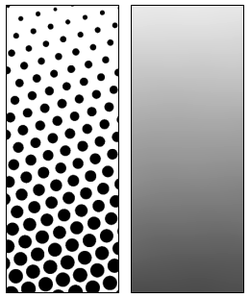

Half-tone : this simulates a continuous shade of an image by using equally spaced dots of different sizes. See the Wikipedia article on Halftone

Duo-tone : is a Half-tone picture made up of two printed colors. See the Wikipedia article on Duotone. This seems to have evolved to also be a generic word for 'color seperation' printing like the four color process below. Duo-tone would only be using TWO colors.

Four-color process : is the process of combining the four basic printing colors (cyan, magenta, yellow, black), to create a picture, image, or colors.

8. Interview a printer to find out the following:

Go interview a printer and get answers to the following questions. Enjoy!

- a. What education is needed to get into the printing field?

- b. What advancement opportunities are available in printing?

- c. What does the future hold for the printing industry?

- d. What do you do in your business to keep customers happy?

- e. What career opportunities related to printing are available?

References

- http://www.printusa.com/glos.htm Glossary of printing terms

- http://www.canadaprintquotes.com/printing101/what_is_a_webpress.asp What is a web press?