AY Honors/Dairying/Answer Key

1

2

The best approach is a holistic one, by taking a close look at the genetics of the calf and the environment. Both of these factors have an effect on the final phenotype. Maternal and paternal characteristics are important as well as the heritability of these traits. When selecting a calf don't always select on appearance. Know that the calf is going to be used for before selection. Characteristics differ between dairy and beef calves.

3

3a

Research has shown that seperating the calf from it's mother immediately to within 4 days reduces stress and seperation anxiety. It also maximizes milk production. Calves need colustrum for the first 1-4 days which gives them immunities. They then go on milk replacer (powder milk based product with additives).

Calves are selected for veal, to raise for meat, to raise as replacement milking cows, or for use as a bull (though most modern dairies use AI now). The selection depends on the breeding (perhaps beef cattle cross for meat), sex, confirmation of the calf, and market conditions. Management of the calf will vary depending on the purpose for which it is raised.

3b

While calfs that are weaned within 4 days will grow more slowly, the value of the milk they would otherwise drink makes early weaning more desirable. Calves should be feed milk replacer, calf manna, and encouraged to start browsing and grazing.

3c

Dairy science and practices have changed drastically since this honor was written. Modern dairies will get a young cow bred by 12 months old and into the milking herd 9 months later.

3d

Young cows need good nutrition to help them produce their first calf. With the birth of the first calf the cow can enter into the milking herd. A cow may have up to ten calves and live up to about 20 years but modern daries agressively cull and replace cows, so a typical cow now lasts about 4 years.

3e

A pregnant and/or lactating cow needs both maintenance ration and extra energy to produce milk and/grow a fetus. Dry and non-pregnant cows need to be fed only the maintenance ration. Requirements for a 400 kg cow are 0.25 kg DCP, 3.0 kg TDN or 10.8 Mcal of ME, 17 g calcium and 13 g phosphorus. Feeding 25 kg of green maize or good quality sorghum containing one per cent DCP, 14 per cent TDN or 60 Mcal ME, 0.6 g calcium and 0.5 g phosphorus per kg of green fodder, meets requirements, as does eight kg of green berseem or lucerne and 5.5 kg of straw. When wheat straw with 1.5 kg of balanced concentrate mixture or 800 g of groundnut cake is fed, the ration is sufficient to maintain the animal.

Care must be taken to ensure the dry cow does not become infected, and to cure any existing infections. The cow must be prepared for lactation again. This article gives a good overview of the drying off process and infection control. http://www.lely.com/en/farming-tips/drying-off-the-dairy-cow

4

There are two broad schools of thought on how to feed cattle. The choice depends on economic, political, and market factors as well as the purpose for which the cattle are raised.

1. Forge based diets: grass, hay, silage

2. Grain based diets: corn, barley, and mixes

Many cows are fed some combination of forge and grain. The milk production of a dairy cow can be enhanced with the use of corn and other grains. These give more energy to produce milk. If cows are kept in a barn mostly they will be fed more grain while cows with access to pasture will get more grass.

5

Cows make milk with their mammory tissues just like all mammals (including humans). To start a cow milking first she must get pregnant (around age 2) and give birth. The farmer then continues to milk the cow and the continued demand for milk causes the cow to continue to produce milk. It is not necessary for the cow to get pregnant or give birth again.

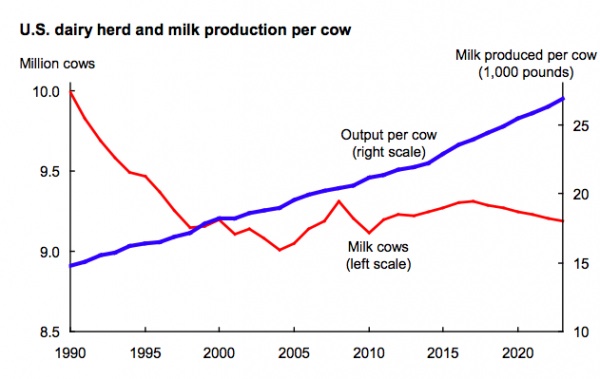

Over the years improved dairy science has lead to a linear growth in milk production per cow over decades with no end in sight for the increases. The United States dairy herd produced 83.9 billion kg (185 billion lbs) of milk in 2007, up from 52.6 billion kg (116 billion lbs) in 1950. Yet there are more than 9 million cows on U.S. dairy farms—about 13 million fewer than there were in 1950. Factors leading to higher milk production include:

- Better control over breeding and the cumulative effects of careful selection over time.

- Culling of lower producing cows.

- Emphasis on cow happiness - soft music, sand beds, lots of rest, heated and air conditioned barns.

- Better quality and engineered feed.

- Scientific study of feed, genetics, and management practices to improve milk production.

Cows are Incredible Article: http://m.washingtonpost.com/blogs/wonkblog/wp/2014/02/17/cows-are-incredible-they-might-just-keep-producing-more-milk-forever/

USDA Chart showing historic and projected milk production per cow and the size of the US dairy herd

6

Hand Milking

Historically, the milking and the processing took place close together in space and time: on a dairy farm. People milked the animals by hand; on farms where only small numbers are kept, hand-milking may still be practiced. Hand-milking is accomplished by grasping the teats (often pronounced 'tits') in the hand and expressing milk by either squeezing the fingers, progressively, from the udder end to the tip or by squeezing the teat between thumb and index finger then moving the hand downward from udder towards the end of the teat. This is repeated, using both hands for speed. Both methods result in the milk that was trapped in the milk duct being squirted out the end into a bucket that is supported between the knees (or rests on the ground) of the milker, who usually sits on a low stool.Traditionally the cow, or cows, would stand in the field or paddock while being milked. Young stock, heifers, would have to be trained to remain still to be milked. In many countries the cows were tethered to a post and milked. The problem with this method is that it relies on quiet, tractable beasts, because the hind end of the cow is not restrained. In cold countries where cows are kept in barns, at least for the winter if not throughout the year, they are still tethered only by the neck or head, particularly where they are kept in small numbers.

Machine Milking

Milking machines are used to extract milk from cows when the herd is larger than about 4 cows. The milking unit is the portion of a milking machine for removing milk from an udder. It is made up of a claw, four teatcups, long milk tube, long pulsator tube, and pulsator. The claw is a manifold which connects the short pulse tubes and short milk tubes from the teatcups to the long pulse tubes and long milk tubes. Claws are commonly made of stainless steel or plastic. Teatcups are composed of a rigid outer shell (stainless steel or plastic), which holds a soft inner liner or inflation. Transparent sections in the shell may allow viewing of liner collapse and milk flow. The annular space between the shell and liner is called the pulsation chamber.

Milking machines work in a way that is different from hand milking or calf suckling. Continuous vacuum is applied inside the soft liner to withdraw milk from the teat by creating a pressure difference across the teat canal (or opening at the end of the teat). Vacuum also helps keep the machine attached to the cow. The vacuum applied to the teat causes congestion of teat tissues (accumulation of blood and other fluids). Atmospheric air is admitted into the pulsation chamber about once per second (the pulsation rate), to allow the liner to collapse around the end of teat and relieve congestion in the teat tissue. The ratio of the time that the liner is open (milking) and closed (massaging or resting) is called the pulsation ratio.

The four streams of milk from the teatcups are usually combined in the claw and transported to the milkline or collection bucket (usually sized to the output of one cow) in a single milk hose. Milk is then transported (manually in buckets) or with a mechanical pump to a central storage vat or bulk tank. Milk is refrigerated on the farm in most countries either by passing through a heat-exchanger or in the bulk tank.

In the photo above is a bucket milking system with the stainless steel bucket visible on the far side of the cow. The two rigid, stainless steel teatcup shells applied to the front two quarters of the cow are visible. The top of the flexible liner is visible at the top of the shells as are the short milk tubes and short pulsation tubes extending from the bottom of the shells to the claw. The bottom of the claw is transparent to allow observation of milk flow. When milking is completed the vacuum to the milking unit is shut off, and the teatcups are removed.

Milking machines keep the milk enclosed and safe from external contamination. The interior 'milk contact' surfaces of the machine are kept clean by a manual or automated washing procedure implemented after milking is completed. Milk contact surfaces must comply with regulations requiring food grade materials (typically stainless steel and special plastics and rubber compounds) and are easily cleaned.

Most milking machines are powered by electricity but, in case of electrical failure, there can be an alternative means of motive power, often an internal combustion engine, for the vacuum and milk pumps. Milk cows cannot tolerate delays in scheduled milking without serious milk production reductions.

The most advanced dairies use robotic milkers. These robots guide the cows into the milking station, scan the cow and record which cow it is, attach to the cow's utter, milk, disengage, measure the amount of milk, and reward the cow with tasty feed, all without the farmer's involvement. This frees the farmer to do other work such as record keeping, crop production and herd management. They also help the farmer get more sleep without the 4:30 AM wake up for milking. Robotics allows 3-4 milkings a day, instead of 1-2 with farmer controlled systems, which has proven to give substantially increased milk yield.

7

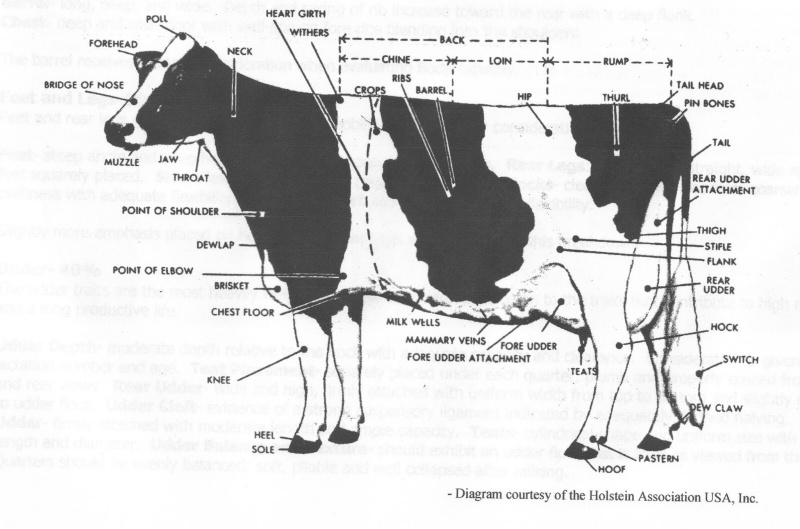

The descriptions of these parts can be found in requirement 6 above.

- Claw

- Teatcups

- Short milk tubes

- Long milk tube

- Short pulse tubes

- Long pulsator tube

- Pulsator

- Collection bucket

8

Mastitis is the inflammation of the mammary gland. It is usually caused by a bacterial infection from Staphylococcus, Streptococcus, E. coli, or Mycoplasma. It can have many causes, including by poor milking practices, poorly fitting teatcups, faulty milking equipment, and freezing. It can be spread to other cows when bedding is shared between an afflicted cow and a healthy cow. It can be prevented by vaccination.

9

Mastitis

Mastitis is an inflammation of the mammary glands. It has been covered in the previous requirement.

Bovine Spongiform Encephalopathy

Bovine Spongiform Encephalopathy (BSE) is more commonly known as mad cow disease. The infectious agent in BSE is believed to be a specific type of misfolded protein called prion. Misfolded prion proteins carry the disease between individuals and cause deterioration of the brain. Different theories exist for the origin of prion proteins in cattle. Two leading theories suggest that it may have jumped species from the disease scrapie in sheep, or that it came from a spontaneous form of "mad cow disease" which has been seen occasionally in cattle for many centuries.

Cattle, like most other food animals, are normally herbivores. In nature, cattle eat grass or grains. In modern industrial cattle-farming, various commercial feeds are used, which may contain ingredients including antibiotics, hormones, pesticides, fertilizers, and protein supplements. The use of meat and bone meal as a protein supplement in cattle feed was widespread in Europe prior to about 1987. Worldwide, soybean meal is the primary plant-based protein supplement fed to cattle. However, soybeans do not grow well in Europe, so cattle raisers throughout Europe turned to the less expensive animal byproduct feeds as an alternative. A change to the rendering process in the early 1980s may have resulted in a large increase of the infectious agents in the cattle feed. A contributing factor seems to have been a change in British laws that allowed a lower temperature sterilization of the protein meal.

Soybean meal is cheap and plentiful in the United States. As a result, the use of animal byproduct feeds was never common, as it was in Europe. However, U.S. regulations only partially prohibit the use of animal byproducts in feed. In 1997, regulations prohibited the feeding of mammalian byproducts to ruminants such as cows and goats. However, the byproducts of ruminants can still be legally fed to pets or other livestock such as pigs and poultry such as chickens. In addition, it is legal for ruminants to be fed byproducts from some of these animals. A proposal to end the use of cow blood, restaurant scraps, and poultry litter (fecal matter, feathers) in January 2004 has yet to be implemented, despite the efforts of some advocates of such a policy, who cite the fact that cows are herbivores, and that blood and fecal matter could potentially carry BSE.

Foot and Mouth Disease

Foot-and-mouth disease (FMD), sometimes called hoof-and-mouth disease, is a highly contagious and sometimes fatal viral disease of cattle and pigs. It can also infect deer, goats, sheep, and other bovids with cloven hooves, as well as elephants, rats, and hedgehogs. Humans are affected only very rarely.

Foot-and-mouth disease is characterized by high fever that declines rapidly after two or three days; blisters inside the mouth that lead to excessive secretion of stringy or foamy saliva and to drooling; and blisters on the feet that may rupture and cause lameness. Adult animals may suffer weight loss from which they do not recover for several months as well as swelling in the testicles of mature males, and in cows, milk production can decline significantly.

One of the difficulties in vaccinating against FMD is the huge variation between viral strains. There is no cross-protection between strains (meaning that a vaccine for one strain won't protect against any others) and in addition, two strains within a given strain may have nucleotide sequences that differ by as much as 30% for a given gene. This means that FMD vaccines must be highly specific to the strain involved. Vaccination only provides temporary immunity that lasts from months to years.

Rinderpest

Rinderpest (RP) is an infectious viral disease of cattle, domestic buffalo, and some species of wildlife, it is commonly referred to as cattle plague. It is characterized by fever, oral erosions, diarrhea, lymphoid necrosis, and high mortality. In German, Rinderpest means cattle-plague. It can be prevented by vaccination. Effective control of rinderpest has been established and by the end of 2010, the FAO plan to have eradicated it completely.

Blackleg

Blackleg is an infectious bacterial disease of sheep and cattle, caused by Clostridium chauvoei bacteria. It is found all over the world. A symptom of blackleg is characteristic swellings which make a cracking sound under pressure. Blackleg vaccine gives immunity against it. Burning the upper layer of soil to eradicate left-over spores is the best way to stop the spread of blackleg from diseased cattle.

Foot Rot

Foot rot, or infectious pododermatitisis, is a hoof infection that is commonly found in sheep and cattle. As the name suggests, it rots away the foot of the animal, more specifically the area between the two toes of the infected animal. It is extremely painful and contagious. It can be treated with a series of medications but if not treated the whole herd can become infected. The cause of the infection in cattle is two anaerobic bacteria (grow without oxygen), Fusobacterium Necrophorum and Bacteroides Melaninogenicus. Both bacteria are common to the environment in which cattle live and the Fusobacterium is present in the rumen and fecal matter of the cattle themselves. Usually there is an injury to the skin between the hooves that allows the bacteria to infect the animal. Another cause of foot rot may high temperatures or humidity causing the skin between the hooves to crack and let the bacteria infect the foot. This is one of the reasons that foot rot is such a major problem in the summer. Foot rot is easily identifiable by its appearance and foul odor. Treatment is usually with an antibiotic medication, and preventing injury to the feet is the best way to prevent foot rot.

10

10a

By-product concentrates commonly available to smallholder farmers are cakes made from mustard, groundnut, and coconut, brans such as rice, wheat, and maize, milling by-products like broken pulses (beans) and non-conventional concentrates including palm kernel, salseed meal, cassava chips, and rubber seedmeal. This list is more asian focused, ingredients will vary based on what is available locally at a reasonable cost. Many concentrates also include added salt and trace minerals.

10b

a measure of the protein available in the feed. Increasing crude protien increase milk yeild to a point. See references for a detailed explanation.

10c

remove from the herd. Non-productive (infertile), diseased, elderly, or lower producing cows are candidates for culling. Culled cows go for slaughter to become meat. About 19% of beef in the US is from dairy cows.

10d

not producing milk. Dairy cows dry up about 2 months before giving birth.

10e

producing milk

10f

the process from when cow first gives birth, is milked, through when it dries up before giving birth again restarting the cycle. Traditionally the cycle takes about a year, but very productive cows may be allowed to go 14-15 months instead.

10g

Oxytocin is a hormone which causes the smooth muscle layer of band-like cells surrounding the alveoli to squeeze the newly-produced milk into the duct system. Oxytocin is necessary for the milk ejection reflex, or let-down to occur.

11

Pasteurization

Milk is an excellent medium for microbial growth,vand when stored at ambient temperature bacteria and other pathogens soon proliferate.

The Centers for Disease Control (CDC) says improperly handled raw milk is responsible for nearly three times more hospitalisations than any other food-borne disease outbreak, making it one of the world's most dangerous food products. Diseases pasteurisation can prevent include tuberculosis, brucellosis, diphtheria, scarlet fever, and Q-fever; it also kills the harmful bacteria Salmonella, Listeria, Yersinia, Campylobacter, Staphylococcus aureus, and Escherichia coli O157:H7, among others.

Pasteurisation is the reason for milk's extended shelf life. High-temperature, short-time (HTST) pasteurised milk typically has a refrigerated shelf life of two to three weeks, whereas ultra-pasteurized milk can last much longer, sometimes two to three months. When ultra-heat treatment (UHT) is combined with sterile handling and container technology (such as aseptic packaging), it can even be stored unrefrigerated for up to 9 months.

History Before the widespread urban growth caused by industrialisation, people kept dairy cows even in urban areas and the short time period between production and consumption minimised the disease risk of drinking raw milk. However, as urban densities increased and supply chains lengthened to the distance from country to city, raw milk (often days old) began to be recognised as a source of disease. For example, between 1912 and 1937 some 65,000 people died of tuberculosis contracted from consuming milk in England and Wales alone. This explains Ellen White's comments about the dangers of milk.

Developed countries adopted milk pasteurization to prevent such disease and loss of life, and as a result milk is now widely considered one of the safest foods. A traditional form of pasteurization by scalding and straining of cream to increase the keeping qualities of butter was practiced in England before 1773 and was introduced to Boston in the USA by 1773, although it was not widely practiced in the United States for the next 20 years. It was still being referred to as a "new" process in American newspapers as late as 1802.

Process Pasteurization typically uses temperatures below boiling, since at very high temperatures, casein micelles will irreversibly aggregate, or "curdle". The two main types of pasteurization used today are high-temperature, short-time (HTST, also known as "flash") and extended shelf life (ESL). Ultra-high temperature processing (UHT, also known as ultra-heat-treating) is also used for milk treatment. In the HTST process, milk is forced between metal plates or through pipes heated on the outside by hot water, and is heated to 72°C (161°F) for 15 seconds. UHT processing holds the milk at a temperature of 138°C (280°F) for a minimum of two seconds. ESL milk has a microbial filtration step and lower temperatures than UHT milk. Milk simply labeled "pasteurized" is usually treated with the HTST method, whereas milk labeled "ultra-pasteurized" or simply "UHT" has been treated with the UHT method. Since 2007, however, it is no longer a legal requirement in European countries (for example in Germany) to declare ESL milk as ultra-heated; consequently, it is now often labeled as "fresh milk" and just advertised as having an "extended shelf life", making it increasingly difficult to distinguish ESL milk from traditionally pasteurized fresh milk. A less conventional, but US FDA-legal, alternative (typically for home pasteurization) is to heat milk at 145 °F (63 °C) for 30 minutes.

Pasteurization methods are usually standardized and controlled by national food safety agencies (such as the USDA in the United States and the Food Standards Agency in the United Kingdom). These agencies require that milk be HTST pasteurized to qualify for the pasteurized label. Dairy product standards differ, depending on fat content and intended usage. For example, pasteurization standards for cream differ from standards for fluid milk, and standards for pasteurizing cheese are designed to preserve the enzyme phosphatase, which aids cutting. In Canada, all milk produced at a processor and intended for consumption must be pasteurized, which legally requires that it be heated to at least 72°C for at least 16 seconds, then cooling it to 4°C to ensure any harmful bacteria are destroyed. The UK Dairy Products Hygiene Regulations 1995 requires that milk be heat treated for 15 seconds at 71.7 °C or other effective time/temperature combination.

A process similar to pasteurization is thermization, which uses lower temperatures to kill bacteria in milk. It allows a milk product, such as cheese, to retain more of the original taste, but thermized foods are not considered pasteurized by food regulators.

Efficacy The HTST pasteurization standard was designed to achieve a five-log reduction, killing 99.999% of the number of viable micro-organisms in milk.[26] This is considered adequate for destroying almost all yeasts, molds, and common spoilage bacteria and also to ensure adequate destruction of common pathogenic, heat-resistant organisms (including Mycobacterium tuberculosis, which causes tuberculosis, but not Coxiella burnetii, which causes Q fever). As a precaution, modern equipment tests and identifies bacteria in milk being processed. HTST pasteurization processes must be designed so the milk is heated evenly, and no part of the milk is subject to a shorter time or a lower temperature.

Even pasteurization without quality control can be effective, though this is generally not permitted for human consumption; a study of farms feeding calves on pasteurised waste milk using a mixture of pasteurization technologies (none of which were routinely monitored for performance) found the resulting pasteurized milk to meet safety requirements at least 92% of the time.

An effect of the heating of pasteurization is that some vitamin, mineral, and beneficial (or probiotic) bacteria is lost. Soluble calcium and phosphorus decrease by 5%, thiamin and vitamin B12 by 10%, and vitamin C by 20%. However, these losses are not significant nutritionally.

Verification Direct microbiological techniques are the ultimate measurement of pathogen contamination but these are costly and time consuming (24-48 hours), which means that products are able to spoil by the time pasteurisation is verified.

As a result of the unsuitability of microbiological techniques, milk pasteurisation efficacy is typically monitored by checking for the presence of alkaline phosphatase, which is denatured by pasteurisation. B. tuberculosis, the bacterium requiring the highest temperature to be killed of all milk pathogens is killed at similar ranges of temperature and time as those which denature alkaline phosphatase. For this reason, presence of alkaline phosphatase is deemed to be an ideal diagnostic tool for pasteurisation efficacy.

Phosphatase denaturing was originally monitored using a phenol-phosphate substrate. When hydrolysed by the enzyme these compounds liberate phenols, which were then reacted with dibromoquinonechlorimide to give a colour change, which itself was measured by checking absorption at 610 nm (spectrophotometry). Some of the phenols used were inherently coloured (phenolpthalein, nitrophenol) and were simply assayed unreacted. Spectophotometric analysis is satisfactory but is of relatively low accuracy because many natural products are coloured. For this reason, modern systems (since 1990) use fluorometry which is able to detect much lower levels of raw milk contamination.[25]

Care of Dairy Appliances

The milking machine gets the most use and abuse of anything on a dairy farm, yet is sometimes taken for granted. Proper equipment care will increase production and reduce frustration. Some farmers choose to have a dairy service perform regular checks and maintenance on their equipment, while other more mechanically gifted farmers so most work themselves. Most farmers take some middle path. From changing the milk filter every day to annual checkups of the whole system, it is important to follow the recommended service intervals. Even though a component like the teat cup may look fine, when it reaches the end of its service life it is developing microscopic holes that can harbour disease.

Keeping all equipment clean with water and food safe cleaners is very important as well to ensure the safety of the milk.

12

This is going to be the hardest part of the honor to arrange if you do not live on a dairy farm.

References

- This article details how cows digest grass to make milk. http://www.dairy.edu.au/discoverdairy/Students/From-Farm-to-Plate/How-Cows-Make-Milk.aspx

- Wikipedia on Cow Feeding http://en.m.wikipedia.org/wiki/Cattle_feeding

- Feeding by age/stage of life. http://www.ilri.org/InfoServ/Webpub/fulldocs/SmHDairy/chap7.html

- http://babcock.wisc.edu/node/150

- detailed explanation of crude protein. http://research.vet.upenn.edu/dairynutrition/ProteininDairyCows/tabid/3715/Default.aspx